Green coffee storaging and dosing system

Optimize your coffee production with a flexible and modular solution designed for precise storage and dosing, ensuring high-capacity operations without compromising space.

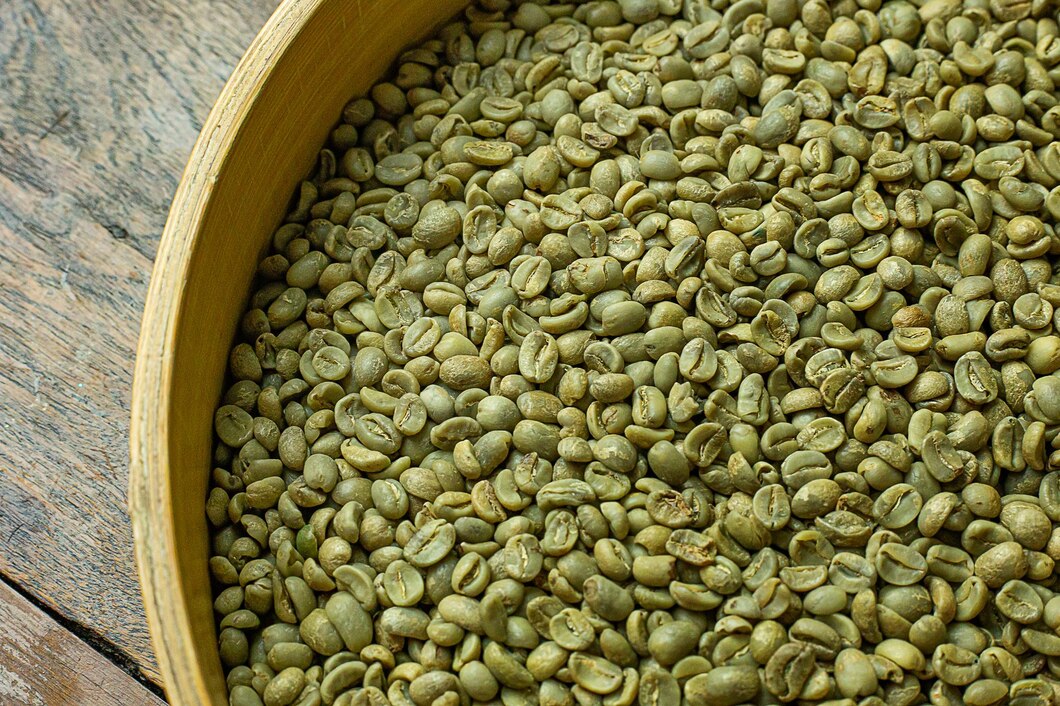

Stores and Doses Green Coffee Beans

The Green Coffee Storaging and Dosing Systems by IMA Coffee Petroncini are designed for precise handling of green coffee beans within processing facilities. Featuring a modular design, this equipment supports seamless integration into existing layouts, optimizing space and enhancing efficiency. Its batch weighing system ensures accurate dosing, vital for maintaining blend consistency and quality. The systems cater to a variety of applications including single-origin and specialty coffee, with a focus on energy efficiency through optimized motor controls. Integrated automation, such as PLC systems, facilitates process monitoring and reduces manual intervention. The equipment, built in high-grade materials, offers durability and resistance to the demanding conditions of coffee pre-processing. Dust aspiration and filtering systems maintain a clean environment, aligning with industry standards for safety and hygiene. IMA Coffee Petroncini also provides customization and engineering support, ensuring that each solution meets the specific needs of your production capacity and facility layout.

Benefits

- Enhances production efficiency with flexible adaptation to facility layouts.

- Minimizes contamination risks through integrated dust aspiration and filtering.

- Increases dosing precision, supporting consistent product quality.

- Reduces operational downtime with automated batch weighing systems.

- Optimizes space usage with modular and space-saving silo designs.

- Applications

- Green coffee, Coffee beans

- End products

- Single-origin green coffee, Raw coffee beans, Green coffee blends, Specialty coffee green beans

- Steps before

- Green Coffee Receiving, Green Coffee Cleaning, Green Coffee Sorting

- Steps after

- Roasting, Roasted Coffee Storage, Packing

- Input ingredients

- green coffee beans, coffee bags, bulk coffee containers

- Output ingredients

- stored green coffee, accurately dosed green coffee, sorted green coffee, dust-free green coffee

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Silo Shape

- Circular, Square, Polygonal

- Installation Location

- Indoor / Outdoor

- Batch Weighing Accuracy

- High Precision

- Silo Capacity

- Variable based on Facility

- Dosing Type

- Rotary Distributors and Weighing Devices

- Dust Aspiration System

- Integrated

- Storage Flexibility

- Adaptable for Future Expansion

- Environment Impact Attention

- Dust Free

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Batch

- Energy efficiency

- Optimised weighing times

- Changeover time

- Flexible layout adaptation

- Cleaning method

- Dust aspiration and filtering systems

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Silo shape

- Circular, polygonal, square

- Silo installation

- Indoor/Outdoor

- Silo material

- Hygienic-design specifications compliant

- Silo size

- Customizable for facility space

- Space optimization

- Modular shape

- Dosing system

- Batch weighing

- Dust control

- Dust aspiration and filtering systems

- Storage shape

- Square, Polygonal, Circular

- Storage type

- Indoor/Outdoor

- Silo design

- Modular, Hygienic

- Batch weighing device

- Integrated beneath silos

- Discharge method

- Rotary distributors, Special dosing valves

- Dust management system

- Dust aspiration and filtering

- Process control

- Petroncini Production Manager®