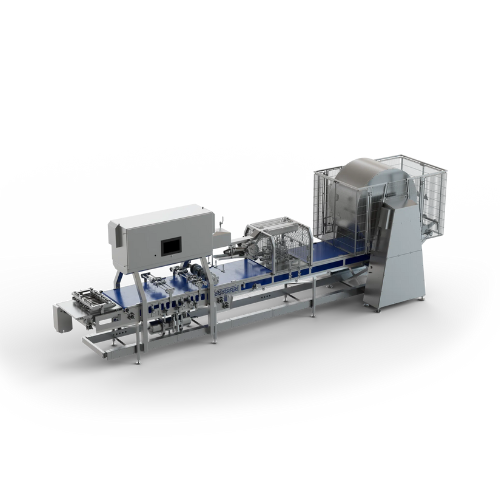

Processing line for spring rolls

Streamline your spring roll production with a compact machine designed to minimize downtime and labor while maximizing consistency and safety through precise dosing, folding, and baking.

Automates Spring Roll Production Processes

The Spring Roll Processing Machine from Cabinplant is a comprehensive solution for automating the production of various spring roll types, including chicken, shrimp, and vegetarian options. This equipment is designed to enhance efficiency and product consistency by integrating dosing, filling, baking, folding, and rolling processes. The system operates with high-speed automation, allowing for continuous production and reducing manual labor to just two operators, thereby lowering operational costs.

With line capacities ranging from 120 to 240 rolls per minute, the machine caters to both small and large-scale food processing businesses. Its compact design ensures minimal space usage, while robust construction facilitates easy maintenance and cleaning. Featuring a user-friendly interface, the machine supports rapid product changeovers with just 30 minutes of downtime, enabling quick adjustments for different recipes and sizes.

Cabinplant’s solution reduces waste through precise raw material usage and provides enhanced food safety by minimizing human contact. Available in configurations suitable for solid and slurry products, it seamlessly integrates into existing production lines, offering flexibility and scalability to meet diverse production demands. With options for various lane setups and drum dimensions, this equipment is tailored to fit specific industrial needs, ensuring optimal performance and reliability.

Benefits

- Increases production efficiency by minimizing manual labor to just two operators.

- Enhances product consistency with precise filling and consistent sheet thickness.

- Reduces operational costs with rapid 30-minute changeovers for different product types.

- Optimizes space utilization with a compact design requiring less production area.

- Boosts food safety by eliminating human cross-contamination risks.

- Applications

- Seafood, Dairy food, Berries, Convenience food, Pet food, Meat, Vegetables, Poultry, Fish

- End products

- Duck spring rolls, Chicken spring rolls, Pork spring rolls, Crab spring rolls, Spring rolls, Shrimp spring rolls, Beef spring rolls, Vegetarian spring rolls

- Steps before

- ingredient preparation, dough mixing, raw material loading

- Steps after

- quality inspection, packaging, storage

- Input ingredients

- batter, dough, filling

- Output ingredients

- spring rolls, spring roll sheets

- Market info

- Cabinplant is known for designing and manufacturing tailored processing solutions for the food industry, specializing in fish, seafood, fruits, and vegetables. They are reputed for their innovative technology and efficiency in delivering customer-specific engineered-to-order equipment.

- Automation

- PLC-controlled

- Capacity

- 120-240 rolls per minute

- Changeover time

- 30 minutes

- Dimensions

- 2177 mm height, 6510 mm length, 1881 mm width

- Drum size (Standard)

- Ø 1200 x 655 mm

- Drum size (Large)

- Ø 1200 x 750 mm

- Width of sheet

- 145-360 mm

- Efficiency

- Increased due to minimal maintenance

- Labor requirement

- Reduced to two operators

- Operation type

- Continuous

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- 30 minutes

- Cleaning method

- Easy access for cleaning

- Energy efficiency

- Low energy usage due to compact design

- Reduction in manual labor

- Reduced to two operators

- Biological compatibility

- Food-safe materials

- Cleanability

- Smooth surfaces for easy cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel, corrosion-resistant materials

- Abrasion resistance

- High durability surfaces

- Density/particle size

- Uniform for consistent processing

- Heat sensitivity

- N/A

- Manual labor

- Reduced to two operators

- Compact footprint

- Yes

- Machine height

- 2177 mm

- Machine length

- 6510 mm

- Machine width

- 1881 mm

- Sheet width for standard drum

- 300 mm

- Sheet width for large drum

- 360 mm

- Discharge method

- Spring roll Sheet folding conveyor

- Compact design

- Space-saving

- Changeover time

- 30 min downtime on product changeover

- Control panel type

- User-friendly operation