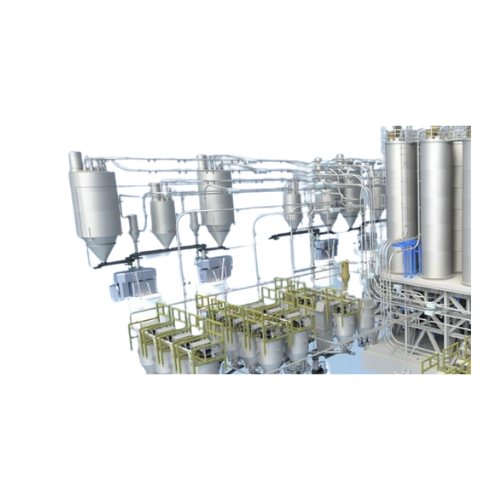

Dispersion paint production systems

Achieve 100% color accuracy and flexible production with our advanced system, ensuring optimal storage, precise weighting, and efficient conveying of dispersion paints.

Manages Precise Dispersion and Transport of Paint Components

Zeppelin Systems offers a comprehensive solution with its range of rotary feeders and diverter valves specifically designed for the dispersion paint industry. These components facilitate the precise handling of pigments, binders, and additives through optimized continuous processes. Suitable for industries focusing on architectural and automotive coatings, they ensure reliable, high-speed operations with seamless integration into existing production lines. Their robust construction supports various product forms, from powders to granules, and the equipment is designed to handle up to industrial scale volumes efficiently. Equipped with advanced PLC controls, these feeders and valves allow for precise rate adjustments and include options for automated operation and remote monitoring, optimizing both energy consumption and process throughput. Constructed with material options like stainless steel, they offer excellent corrosion resistance critical for chemical processing. The system supports easy cleaning and maintenance, featuring components that help minimize downtime, providing a reliable and efficient solution for modern paint manufacturing needs.

Benefits

- Enhances production efficiency with precise material handling and transport.

- Reduces operational costs through automated PLC control and remote monitoring.

- Offers flexibility with customizable material and configuration options for diverse applications.

- Minimizes downtime with easy maintenance and quick-cleaning components.

- Ensures chemical compatibility and longevity with corrosion-resistant construction.

- Applications

- Binders, Additives, Fillers, Pigments, Dispersion paints, Titanium oxide

- End products

- Wood finishes, Titanium dioxide processing products, Polymer additives, Specialty resins, Automotive coatings, Protective sealers, Cementitious fillers, Industrial coatings, Architectural paints, Textile pigments

- Steps before

- Material Selection, Material Preparation, Grinding, Mixing

- Steps after

- Quality Control, Storage, Filling, Packing

- Input ingredients

- fillers, binders, pigments, additives, titanium oxide, powdery raw materials, recipe components, base materials, raw materials

- Output ingredients

- dispersion paints

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Color accuracy

- 100%

- Conveying method

- Pneumatic / Mechanical

- Discharge method

- Pneumatic / Vibratory bottom

- Filtration type

- Jet filters / Aspiration systems

- Weighing accuracy

- High precision

- Conveying speed

- Customizable

- Dosing type

- High-precision

- Material feeding type

- Automatic / Manual

- Automation level

- High

- System Testing Capability

- Industrial scale testing

- Dust-free operation

- Aspiration systems

- Handling capability

- High-capacity for titanium oxide

- System efficiency

- Optimized performance

- Control system

- Open architecture

- Silo design

- Customizable cone opening angle

- Discharge efficiency

- Residue-free

- Feeding time

- Short

- Working mechanism

- Rotary feeder, diverter valve

- Integrated steps

- Storage, discharge, filtration, conveying, weighing, dosing

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Fast, tailored for flexibility

- Energy efficiency

- Optimized for minimal downtime

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Tank shape

- Conical / Cylindrical

- Tank size

- Variable based on application

- Discharge method

- Vibratory bottom / Pneumatic

- Control panel type

- Integrated / Detached

- Conveying type

- Pneumatic / Mechanical

- Silo type

- Storage / Blending / Process

- Silo construction

- Modular / Bolt-Tec

- Mixing type

- High intensity / Cooling / Universal

- Rotary sifter type

- RS rotary sifter

- Control panel type

- PLC / HMI

- Discharge method

- Vibratory / Pneumatic

- Automation level

- Manual / PLC / SCADA

- Integration possibilities

- Seamless with existing systems