Cip & Sip systems for pharmaceutical cleaning

Ensure effective cleaning and sterilization in production lines with customizable CIP and SIP systems, streamlining validation processes and reducing downtime, ideal for maintaining sterility and maximizing efficiency in pharmaceutical and biotech environments.

Cleans and Sterilizes Pharmaceutical Production Equipment

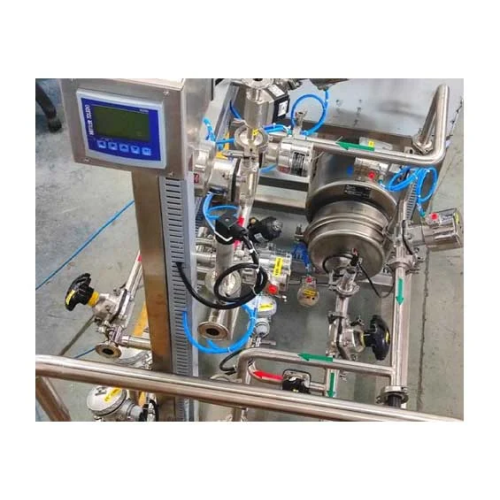

Fabtech’s CIP & SIP Skid Mounted Systems are designed for pharmaceutical, biotech, and healthcare industries, ensuring reliable cleaning and sterilization in compliance with GMP and USFDA standards. These systems utilize high-quality orbital welding and electropolished surfaces to maintain optimal hygiene. They offer customizable configurations, including dosing options for enhanced cleaning efficiency and jacketed/non-jacketed tanks to suit your precise needs. Seamlessly integrating into your production line, they improve uptime by reducing cleaning intervals. Supported by extensive documentation dossiers, these systems simplify validation, making them ideal for producing high-purity monoclonal antibodies, vaccines, insulin, and other critical healthcare products.

Benefits

- Enhances operational efficiency by reducing cleaning and sterilization time.

- Lowers contamination risk with electropolished surfaces and high-quality welding.

- Facilitates regulatory compliance with comprehensive validation documentation.

- Customizable setup optimizes integration into existing production lines.

- Decreases downtime, leading to increased overall productivity.

- Applications

- Biopharmaceuticals, Healthcare products, Pharmaceuticals

- End products

- Vaccines, Nutritional supplements, Insulin, Contact lenses, Monoclonal antibodies, Sterile surgical equipment, Injectable drugs, Tablets, Diagnostic reagents

- Steps before

- Water Purification, Ingredient Mixing, Material Preparation

- Steps after

- Sterilization, Process Validation, Quality Control, Packaging

- Input ingredients

- water, cleaning agents, acid, alkali

- Output ingredients

- cleaned equipment, validated cleaning processes

- Market info

- Configuration

- Customisable

- Space Saving Option

- Tankless

- Surface Finish

- Electropolished to less than 0.4 RA microns

- Welding Quality

- High quality orbital welding with boroscopy and videoscopy

- Dosing Option

- Acid/alkali dosing

- Tank Type

- Jacketed/non jacketed

- Cleaning Method

- CIP / SIP

- Automation level

- Manual / PLC / SCADA

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Batch vs. continuous operation

- Batch / Inline Continuous

- Energy efficiency

- 0.5–2 kWh/kg moisture

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Cleaning methods

- CIP / SIP

- Tank Configuration

- Jacketed/Non-jacketed

- Space Saving Design

- Tankless option

- Contact Surface Finish

- Electropolished to less than 0.4 RA microns