Industrial potato flake production line

Maximize yield and quality in potato processing by integrating advanced pre-cleaning, peeling, and drying technologies, ensuring optimal product consistency and minimal waste in flake production.

Processes Potatoes into Flakes and Snacks

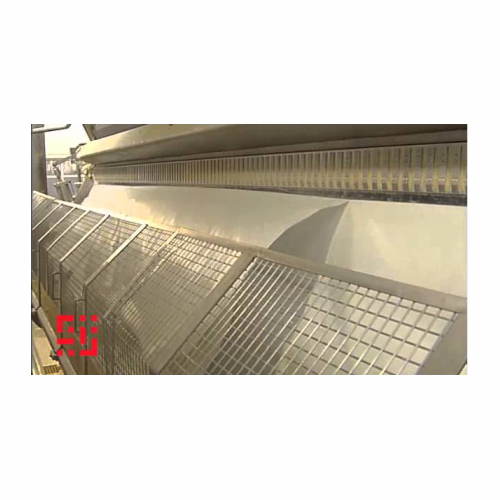

The Flake Line from Kiremko is a comprehensive potato processing system designed to transform raw potatoes into a variety of end-products, including potato flakes, instant mashed potatoes, and pellet snacks. Utilizing an integrated series of robust equipment such as cyclone destoners, drum washers, and steam peelers, this line ensures optimal cleanliness and peeling precision.

Its multi-stage process includes precise weighing and dosing systems that manage the flow of ingredients with high accuracy, while cutting and sizing machines like the Idaho Steel slicer optimize the blanching efficiency. The line’s screw type blanchers and coolers regulate product temperature, essential for consistent quality and ease of rehydration.

Capable of processing up to 70 tons per hour, the Flake Line is PLC-controlled, allowing for seamless integration into existing production environments. Its energy-efficient operation and durable stainless steel construction ensure longevity and reduced operational costs. The system accommodates customization to meet specific production needs, supported by Kiremko’s engineering expertise. Additionally, its design emphasizes quick maintenance and cleaning, enhancing uptime and production line efficiency.

Benefits

- Enhances product quality with precision peeling and optimal sizing, minimizing material loss.

- Increases operational efficiency, processing up to 70 tons per hour with seamless integration into production lines.

- Reduces energy consumption with efficient temperature regulation in blanching and cooling processes.

- Lowers maintenance costs through durable construction and design focused on easy cleaning and accessibility.

- Offers flexible customization options to accommodate specific production requirements, supported by engineering expertise.

- Applications

- Hash browns, Potato flakes, Pellet snacks, Potato mash, Potato chips, Formed mash, French fries

- End products

- Hash brown patties, Potato crisps, Instant mashed potatoes, Extruded pellet snacks, Formed potato patties, Ready-to-eat french fries

- Steps before

- Pre-cleaning, Peeling, Weighing and dosing, Cutting and sizing, Blanching, Cooling

- Steps after

- Cutting and sizing, Packing

- Input ingredients

- potatoes, raw potatoes, clay, sand, soil

- Output ingredients

- potato flakes, flakes, clean potatoes, peeled potatoes, sized potatoes, blanched potatoes, dried potato flakes, milled potato flakes

- Market info

- Kiremko is known for manufacturing industrial equipment for the potato processing industry, specializing in engineered-to-order solutions, with a strong reputation for innovation, quality, and reliability in turnkey processing lines and individual machines.

- Capacity

- Up to 70 tons per hour

- Peeling Thickness

- Millimeter accuracy

- Automation

- PLC-controlled

- Dosing Accuracy

- Loss-in-weight principle

- Cooling Temperature

- To desired retro-gradation specification

- Drying Method

- Steam-heated drum dryer

- Milling Size

- 1.6 mm x 1.6 mm to 20 mm x 20 mm

- Pre-cleaning integration

- Inline

- Peeling precision

- Millimeter-level

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Batch

- Cleaning method

- CIP

- Cooling integration

- Screw type cooler

- Energy efficiency

- Low energy consumption

- Drying process

- Drum dryer

- Material throughput

- Up to 70 tons/hour

- Maintenance

- Low maintenance

- Control panel type

- PLC-controlled

- Compact footprint

- Available in different capacities up to 70 tons per hour

- Discharge method

- Ferris wheel, pump system, or outfeed screw

- Drum size

- Various sizes for Drum washer and Drum dryer

- Machine material

- Stainless steel, polyurethane layer

- Rotating brush

- Durable and wear-proof

- Feed type

- Gravity fed into slicer

- Cooling medium

- Water flow and air extraction

- Control panel type

- PLC-controlled

- Discharge method

- Ferris wheel, pump system, or outfeed screw

- Cooling method

- Screw type cooler

- Blancher type

- Screw type blancher