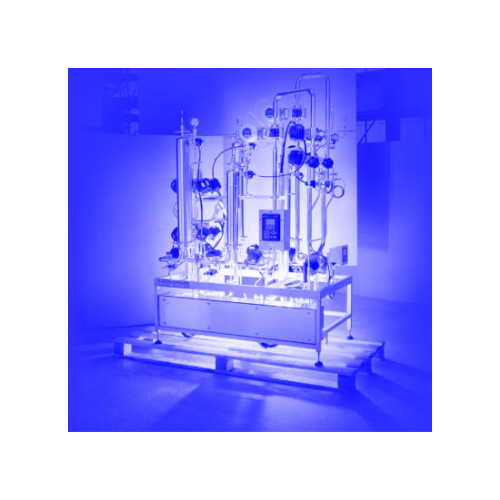

Filter stations for sterile filtration in biopharmaceuticals

Ensure sterility and precision in your biopharmaceutical processes with filter stations designed to support critical filtration and dosing requirements, safeguarding product integrity and optimizing process efficiency.

Sterilizes and Filters Biopharmaceutical Media and Solutions

Bioengineering’s Filter Stations are engineered to provide effective sterilization and filtration solutions for biopharmaceutical production, addressing the stringent needs of cell culture media and dosing agents. Designed to integrate seamlessly into both small labs and large-scale production facilities, these stations offer customizable configurations with options for preliminary, sterile, and virus filters working in series. Capable of processing flow rates from several liters per hour up to 10 m³/h, they ensure adaptability across various scales. Featuring CIP and SIP capabilities, these filter stations are PLC-controlled for full process automation, enhancing operational efficiency and safety with integral safety tests and flow monitoring. Constructed from high-quality materials suitable for sterile environments, they meet cGMP compliance, emphasizing reliable performance in producing vaccines, monoclonal antibodies, and recombinant proteins. Bioengineering’s robust design supports easy maintenance with available documentation and engineering support for customized solutions.

Benefits

- Enhances process safety with integrated flow rate and filter integrity monitoring.

- Streamlines operations with fully automated CIP and SIP functionality.

- Increases production efficiency by processing up to 10 m³/h.

- Supports regulatory compliance with cGMP standards.

- Reduces risk of contamination with sterile filtration of sensitive media.

- Applications

- Large-scale production facilities, Small laboratories, Biotechnological research, Cell culture media, Biopharmaceuticals, Dosing agents

- End products

- Recombinant proteins, Cell therapy products, Vaccines, Buffer solutions, Custom filtration solutions, Monoclonal antibodies, Culture media supplements, Hyaluronic acid

- Steps before

- Media Preparation, Solution Mixing

- Steps after

- Sterilization, Filtration, Dosing

- Input ingredients

- cell culture media, dosing agents, media lines, preliminary filters, sterile filters, virus filters

- Output ingredients

- sterile solutions, filtered media, virus-free media

- Market info

- Bioengineering is known for its expertise in designing and manufacturing customized bioreactors and fermenters, serving the biotechnology and pharmaceutical industries. They are reputed for high-quality, engineered-to-order solutions and innovative process technologies.

- Automation

- CIP / SIP capable

- Flow rate

- Several liters/hour to 10 m³/h

- Filter capacity

- Preliminary, sterile, virus filters

- Filter type

- Code 7 filters

- Safety Features

- Filter integrity tests, flow rate measurement, pressure measurement

- Compatible Processes

- Preliminary, sterile, virus filtration

- Sterilization capability

- Fully automated and sterilizable

- Media Line Configuration

- Multiple lines with customizable filter housings

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- CIP 121°C / SIP 135°C

- Cleaning method

- CIP / Manual

- Compatibility with Code 7 filters

- All makes

- Heat sensitivity

- Sensitive to denaturation

- Filter Type

- Preliminary, Sterile, Virus

- Flow Rate

- Several L/h to 10 m³/h

- Filter Compatibility

- All Code 7 Filters

- Filter Housing Size

- Customizable

- Media lines

- Multiple lines possible