Feeding, dosing, weighing and mixing system for granulate

Achieve precise granulate mixing and rapid color changes with an integrated system that combines transporting, dosing, weighing, and mixing, ensuring uniform product quality and efficient production line integration.

Transports, Doses, Weighs, and Mixes Granulates

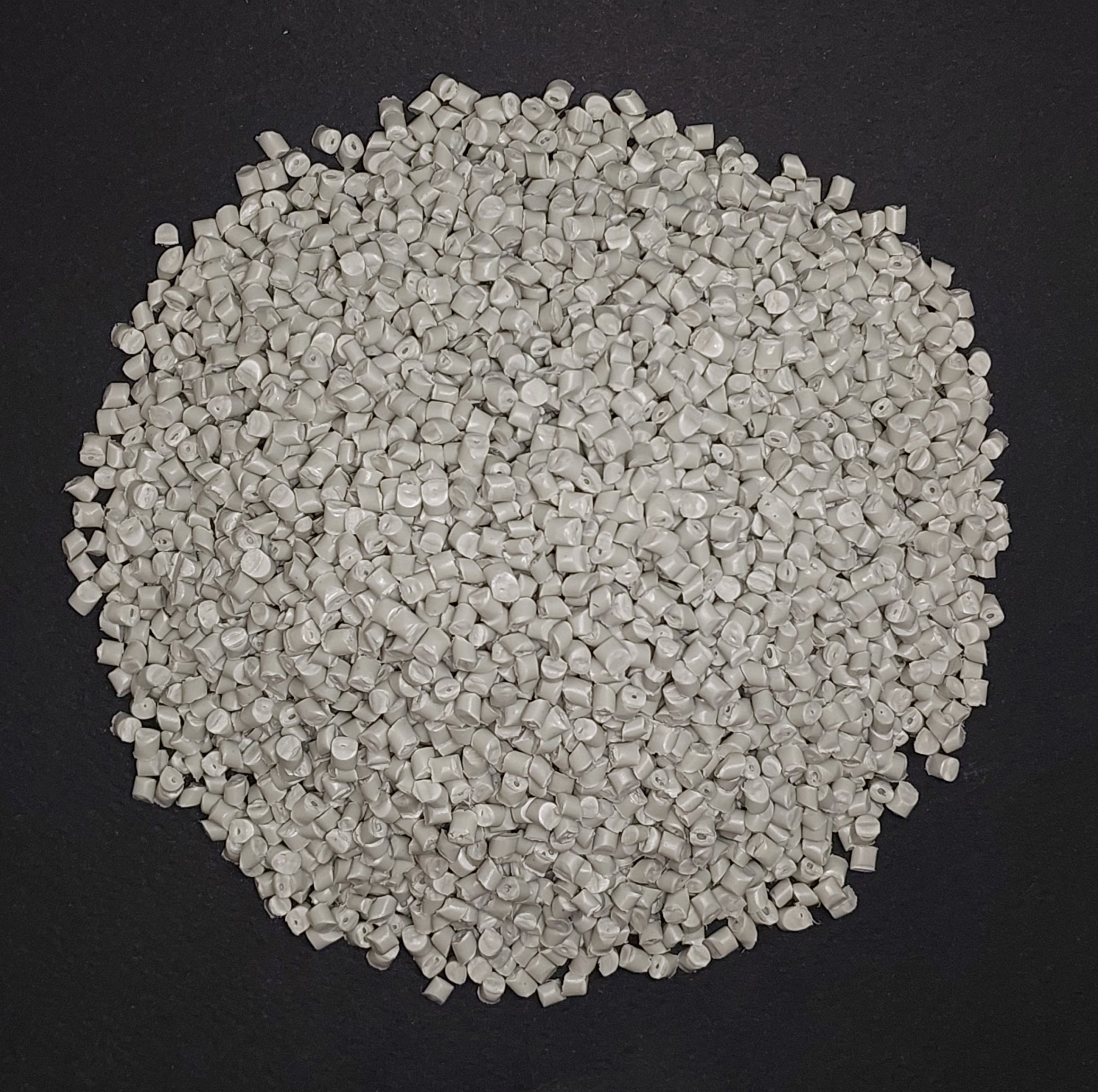

The AZO®MIXOMAT from AZO GmbH & Co. KG is an all-in-one system that revolutionizes your production line by effectively transporting, dosing, weighing, and mixing granulates. Constructed with a conical housing and geared motor, it simplifies complex operations, making it ideal for plastic processing and compounding. The system efficiently processes polypropylene granules, colored masterbatch pellets, recycled plastic compounds, titanium dioxide pigment, and antioxidant additives with a throughput ranging from 150 kg/h to 2.5 t/h.

Its compact design integrates seamlessly into existing lines, eliminating the need for separate differential dosing scales. Operationally, it supports both batch and discontinuous processes under gravimetric conditions, ensuring precise throughput registration. The MIXOMAT is available in mild steel or stainless steel, catering to specific operational and cleaning requirements. By combining air-purged filters and conveying systems, it guarantees minimal product loss and reduces energy consumption. This equipment is a pivotal asset for medium to high throughput operations in plastics, chemical, and packaging industries, offering extensive customization through AZO’s collaboration with extrusion machine manufacturers.

Benefits

- Enhances production efficiency by integrating multiple processes into a single compact system.

- Facilitates quick material changeovers and cleaning, minimizing operational downtime.

- Ensures consistent product quality with high repetition accuracy in mixing and weighing.

- Adapts easily to varying production demands, supporting medium to high throughput operations.

- Saves space and costs by eliminating the need for differential dosing scales.

- Applications

- Additives, Granulates, Pigments, Masterbatch, Re-work

- End products

- Polypropylene granules, Recycled plastic compounds, Antioxidant additives, Titanium dioxide pigment, Colored masterbatch pellets

- Steps before

- Purification, Drying

- Steps after

- Packing, Extrusion, Foil Production

- Input ingredients

- granulate, masterbatch, re-work, pigments, additives

- Output ingredients

- mixed granulate, processed masterbatch, processed re-work, pigment mixtures, additive mixtures

- Market info

- AZO is renowned for designing and manufacturing automated bulk material handling systems, specializing in mixer feeding, ingredient automation, and process control, known for their reliability and tailored solutions in the food, pharmaceuticals, and chemical industries.

- Accuracy

- High repetition accuracy

- Capacity

- 150 kg/h to 2.5 t/h

- Dosing type

- Gravimetric

- Feeding type

- Discontinuous

- Material Compatibility

- Mild steel or stainless steel

- Automation

- Automatic

- Cleaning method

- Easy cleaning, large cleaning door

- Modularity

- Compact, pre-assembled modules

- Compressed Air Usage

- For discharge valve operation

- Batch vs. continuous operation

- Discontinuous / Batch

- Integrated steps

- Transporting, dosing, weighing, mixing

- Automation level

- PLC-controlled

- Cleaning method

- Easy cleaning / Quick-release door

- Changeover time

- Rapid color change

- Cleanability

- Easy to clean

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Available in stainless steel

- Density/particle size

- 0.5–2.5 g/cm³

- Granulate mixing

- Masterbatch, re-work, pigments, additives

- Machine footprint

- Compact

- Shape

- Conical

- Feed method

- Switching valves

- Discharge method

- Compressed air operated valve

- Material

- Mild steel or stainless steel

- Finish

- Ground and polished

- Cleaning features

- Large cleaning door with quick-release fasteners

- Material of construction

- Mild steel / Stainless steel

- Cleaning method

- Easy cleaning / Quick-release fasteners

- Mixing tool configuration

- Geared motor driven

- Discharge method

- Compressed air operated valve

- Integration capability

- Compatible with FLEXIDOS® and AZODOS®

- Module variants

- MIXOMAT mixer / MIXOMAT scale / MIXOMAT conveying scale

- Finish type

- Ground and polished finish