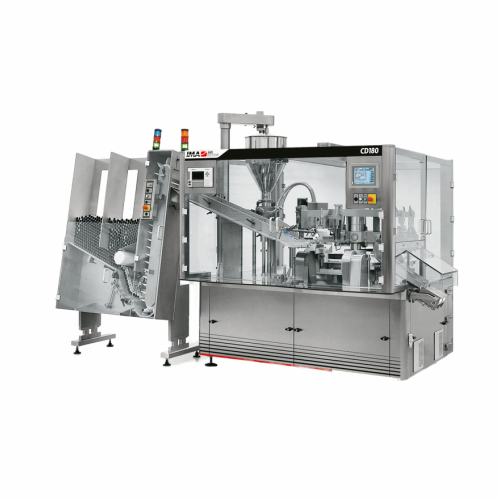

Automatic tubefiller for pharmaceutical tubes

Streamline your tube packaging process with this versatile solution, optimized for high-speed filling and precise dosing to enhance production efficiency across diverse liquid products.

Fills, Seals, and Doses Liquid Tubes

The Comadis CD180 from IMA Group is an engineered-to-order tubefiller designed for demanding production environments across pharmaceutical, cosmetics, and personal care industries. This twin-nozzle machine adapts to varied production needs, offering both high-speed operation up to 180 tubes per minute and customizable configurations, including a fully robotized tube feeder. It features a servo-driven dosing pump and servo-controlled diving nozzles for precise liquid management and cleaning efficiency. Suitable for a wide range of applications, the CD180 ensures product integrity in filling, sealing, and dosing processes. Its integrated electrical cabinet and tool-free change of size parts streamline maintenance, while compatibility with sustainable materials supports eco-friendly initiatives. Compliance with pharmaceutical industry standards is assured, making it an ideal solution for manufacturers seeking efficient and adaptable tube-filling operations.

Benefits

- Enhances production efficiency with high-speed tube filling up to 180 tubes per minute.

- Offers flexibility and scalability with customizable robotized configurations for varied batch sizes.

- Streamlines maintenance with easy disassembly and tool-free size changeover.

- Supports sustainability initiatives by handling eco-friendly packaging materials.

- Ensures product precision and reduces waste with servo-driven dosing and 3-way valve control.

- Applications

- Sustainable packaging, Personal care products, Food and dairy, Confectionery, Coffee, Cosmetics, Home care products, Tea and beverage, Pharmaceuticals

- End products

- Steps before

- Tube preparation, Material blending, Tube sorting

- Steps after

- Sealing, Batch data collection, Secondary packaging

- Input ingredients

- tubes, bulk materials, liquid products

- Output ingredients

- filled tubes, sealed tubes

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Mechanical speed

- Up to 180 tubes/min

- Filling volume

- 2-250 ml. (on request up to 350 ml.)

- Tube diameter

- 10-50 mm

- Tube length

- 60-250 mm

- Working stations

- 15

- Dosing pump

- Fully servo-driven

- Automation

- Fully robotized tube feeder available

- Nozzle type

- Servo-controlled diving (or stationary) with positive shut-off valve

- Working Mechanism

- Mechanical with servo-driven dosing pump

- Automation Level

- Fully robotized with servo-controlled elements

- Batch vs. Continuous Operation

- Batch

- Changeover Time

- Quick interchangeability of parts without tools

- CIP/SIP

- Stationary nozzle cleaning by air blow

- Cleaning Method

- Air cleaning

- Size Change Flexibility

- Simplified and tool-free

- Energy Efficiency

- Efficient servo-driven components

- Integrated Steps

- Automatic/robotized tube feeding

- Sustainability of materials

- Sustainable plastic materials

- Machine footprint

- Compact with integrated electrical cabinet

- Nozzle Type

- Twin-nozzle, servo-controlled options

- Customization options

- Individually tailored configurations available

- Tube diameter

- 10-50 mm

- Tube length

- 60-250 mm

- Feed method

- Automatic/robotized tube feeders

- Discharge method

- Positive shut-off valve with air blow cleaning

- Material compatibility

- Sustainable plastic materials

- Nozzle type

- Servo-controlled diving or stationary

- Tube feeder type

- Automatic/robotized

- Configuration

- Basic to fully robotized

- Dosing pump type

- Easy-to-disassemble, fully servo-driven

- Machine layout

- Integrated electrical cabinet

- Customization options

- Designer seals

- Configurable via HMI

- Stroke, acceleration, deceleration