Single screw batch feeder with stirring agitator for powders and pellets

Ensure precise ingredient control and consistency with a feeder that integrates seamlessly into your batch processing line, optimizing throughput with high weighing accuracy and adjustable feed rates.

Ensures Precise Dosing and Feeding

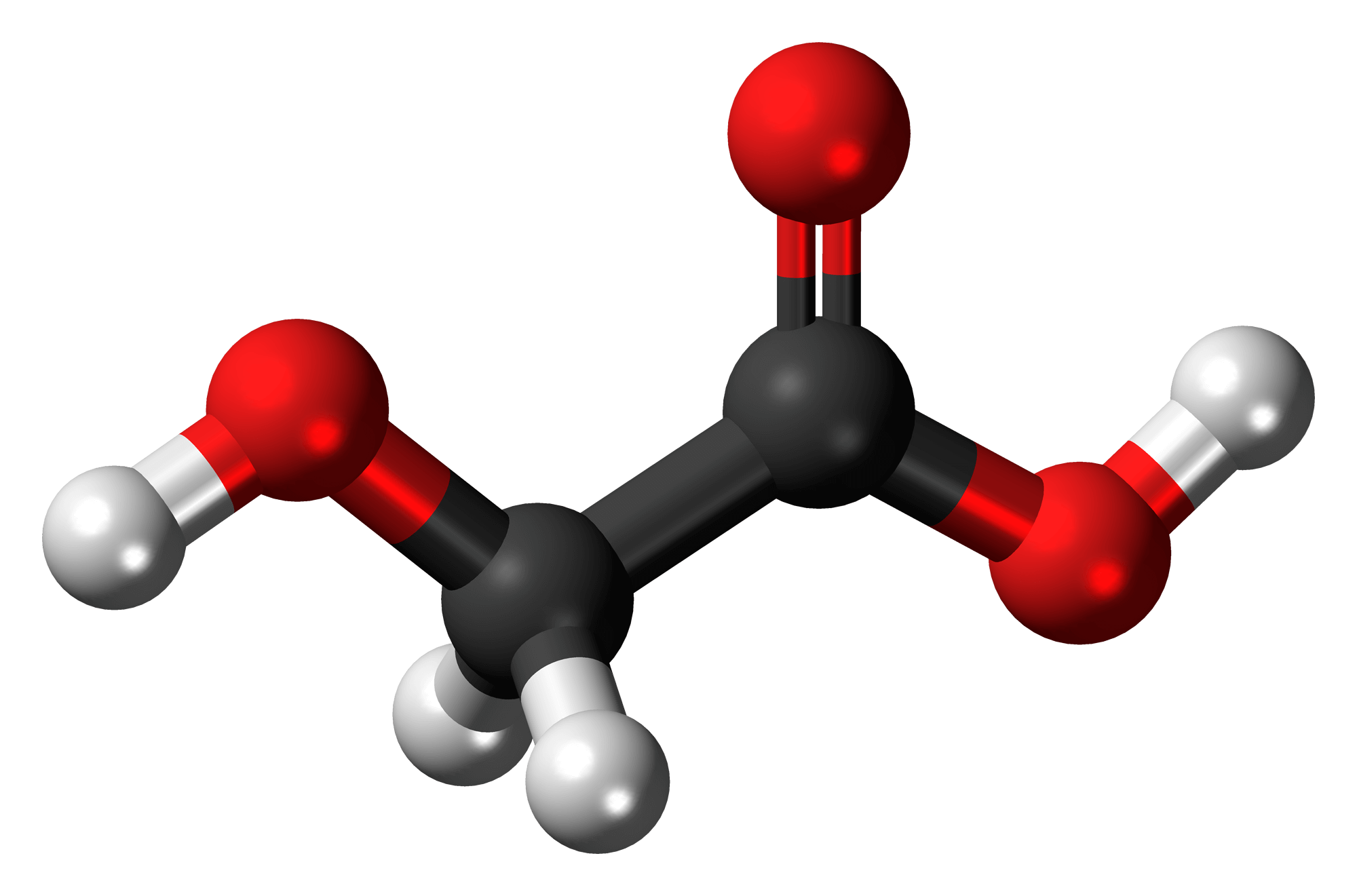

The Single Screw Batch Feeder with Stirring Agitator, offered by Solids Process Solutions (SPS), is designed for precise loss-in-weight dosing of powders and granules. Its stainless steel construction features a stirring agitator for consistent screw filling, essential for industries like dairy, chemicals, and pharmaceuticals, producing items from ethylene glycol to pet food kibble. This feeder allows quick adaptation with interchangeable screws, accommodating varied ingredients and feed rates. The high-tech weighing system ensures accuracy by computing target weights and halting operations upon attainment. The feeder integrates into processing and pre-processing operations, facilitating batch and continuous processes. For easy maintenance, it includes an option for rapid cleaning, and its modular design supports seamless integration into existing setups, enhancing operational efficiency.

Benefits

- Ensures high batch accuracy for consistent product quality.

- Minimizes material wastage with precise weight-based dosing.

- Reduces changeover time with quick adjustment for different feed rates.

- Streamlines cleaning processes, reducing downtime.

- Enhances operational efficiency by integrating seamlessly into production lines.

- Applications

- Food, Fine chemical, Feed, Recycling, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Corn flour, Color masterbatch, Mineral supplements, Polyethylene granules, Liquid detergents, Milk powder, Ethylene glycol, Fish pellets, Cattle feed, Protein supplements, Tablets, Recycled plastic pellets, Dog food kibble, Pharmaceutical excipients

- Steps before

- Ingredient Preparation, Grinding, Mixing, Material Loading

- Steps after

- Weighing, Batch Dosing, Quality Inspection, Packing

- Input ingredients

- powders, pellets, changing ingredients

- Output ingredients

- consistent screw filling, mass flow of solids, target weight batch

- Market info

- Batch dosing

- Loss-in-weight

- Material

- Stainless steel

- Hopper filling method

- By weight

- Automation

- Automatic Rate Turndown (“A.R.T.”) mode

- Weighing accuracy

- High

- Screw type

- Interchangeable

- Screw tube type

- Interchangeable

- Agitation method

- Stirring agitator

- Working mechanism

- Single screw with stirring agitator

- Integrated steps

- Batch dosing with loss-in-weight system

- Automation level

- Automatic stopping at target weight

- Batch vs. continuous operation

- Batch

- CIP/SIP

- Easy and quick cleanable version

- Abrasion resistance

- Suitable for abrasive materials

- Biological compatibility

- Compatible with food industry standards

- Cleanability

- Easy and quick cleanable

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Density/particle size

- Compatible with 0.5–2.5 g/cm³ / fine powders to pellets

- Control panel type

- Separate hinge motor

- Discharge method

- Screw

- Compact footprint

- Yes

- Material

- Stainless steel

- Cleaning method

- Easy and quickly cleanable

- Adjustability

- Interchangeable screws and screw tubes

- Control panel type

- Interchangeable

- Agitator type

- Stirring agitator

- Screw type

- Interchangeable screws

- Tubes type

- Interchangeable screw tubes