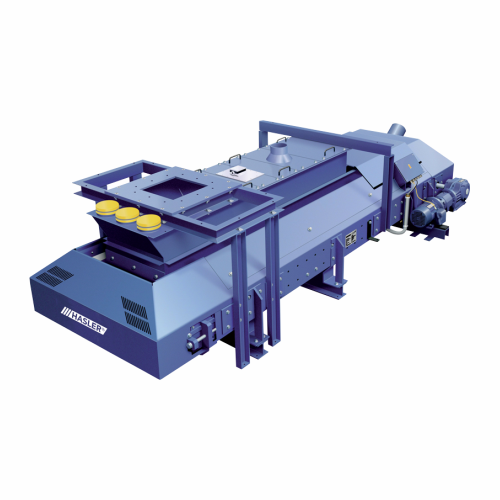

Powder belt feeder for accurate powder metering

Achieve precise powder metering with a specialized feeder that maintains dosing accuracy and ensures stable material flow for seamless integration into your high-demand industrial processes.

Precisely Feeds and Conveys Powdered Materials

The POWDRIT Precision Belt Feeder from HASLER Group is engineered to deliver accurate dosing and stable conveyance of powdered materials across various industrial processes. Its multi-stage feeding system incorporates a high-quality conveyor belt, an inlet hopper, a weighbridge, and a settling chamber, ensuring precise and consistent material flow. Catering to industries such as cement, fertilizers, and technical ceramics, POWDRIT is vital for producing items like cement mix and titanium dioxide pigments. With precision accuracy at ±1%, it handles demanding operational conditions efficiently. The system’s modularity allows for diverse applications, as it is available in five belt widths and four lengths. Integration into existing control systems is seamless, thanks to the SCMIII digital controller, which offers real-time data and alarm monitoring. Designed with durability and ease of maintenance in mind, the POWDRIT ensures minimal downtime with accessible servicing features. Its dust extraction hood maintains a clean working environment, crucial for safety in powder handling operations.

Benefits

- Ensures precision dosing with ±1% accuracy, enhancing product consistency.

- Modular design accommodates various application needs, providing flexible integration.

- Reduces maintenance time with simplified servicing and a robust construction.

- Maintains a safe working environment with an efficient dust extraction system.

- Optimizes production flow with real-time monitoring through digital control systems.

- Applications

- Polymers, Metal powders, Minerals, Coal, Fertilisers, Specialty acids, Amino, Technical ceramics, Resins, Powders, Pigments, Cement

- End products

- Activated carbon, Epoxy resins, Titanium dioxide pigments, Npk fertilizer granules, Tungsten metal powders, Citric acid, Cement mix, Polypropylene pellets, Silica minerals, Amino acid supplements, Alumina substrates

- Steps before

- Pre-dosing, Material Loading, Material Preparation

- Steps after

- Quality Control, Packaging, Dust Extraction

- Input ingredients

- powdered materials, powders, pigments, coal

- Output ingredients

- precisely metered powder, measured powdery materials

- Market info

- HASLER Group is known for manufacturing and supplying industrial engineered-to-order (ETO) equipment, specializing in mixing, filtration, and sealing solutions for various industries, with a reputation for quality and innovation in handling challenging process applications.

- Accuracy

- ±1%

- Belt Width

- Available in five widths

- Belt Length

- Available in four lengths

- Belt Material

- High-quality conveyor belt

- Dust Extraction

- Comprehensive system

- Sensor Type

- SFT digital sensor (optional)

- Automation

- Electronically controlled

- Automation level

- PLC-controlled

- Batch vs. continuous operation

- Continuous

- Changeover time

- Quick-change design

- Cleaning method

- Manual

- Energy efficiency

- Optimized for low consumption

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- Various powder densities and sizes

- Anti-static Handling

- ATEX compliant

- Compact footprint

- Modular design

- Discharge method

- Conveyor belt

- Control panel type

- SCMIII controller

- Chassis dimensions

- Variable width and length

- Belt width options

- Multiple widths available

- Belt length options

- Multiple lengths available

- Settling chamber

- Sealed chamber

- Control panel type

- SCMIII controller

- Belt width options

- Five belt widths available

- Belt length options

- Four lengths available in standard configuration

- Integration possibilities

- SCMIII data collection and regulation functions

- Modular design

- Adaptable in terms of length and width