Speed controller for feeders

Ensure precise material flow by integrating this speed controller, ideal for managing both volumetric and gravimetric feeder operations seamlessly.

Controls Feeding Rates for Precision Dosing

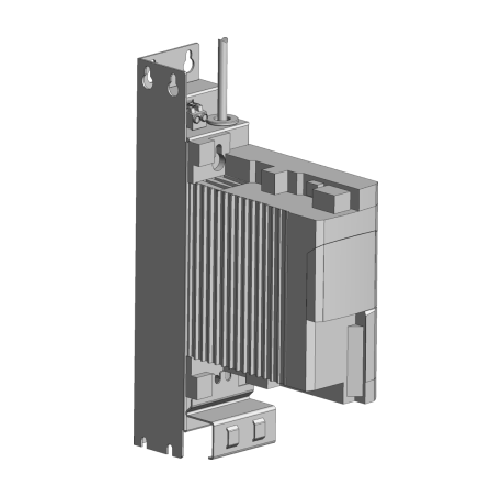

The Speed Controller from Solids Process Solutions (SPS) is a robust solution for optimizing the performance of both volumetric and gravimetric feeders. Designed with frequency control and available as models FC-CM and FC-CB, this equipment allows for precise control over feeding rates, ensuring consistency in the production of products such as chemical additives, pharmaceutical tablets, and pet food kibbles. The speed controller is engineered to seamlessly integrate into pre-existing production lines, and is suitable for a variety of industries including aquafeed, petrochemical, and food processing. With options for both 1 phase and 3 phase operations, it delivers improved energy efficiency and operational flexibility. The FC-CM model features a closed enclosure for direct feeder installation, while the FC-CB model allows for DIN-rail mounting in a control cabinet, facilitating easy maintenance and system upgrades. Designed for rugged industrial environments, the Speed Controller offers durable performance with full compliance to industry standards, supporting operations in demanding settings.

Benefits

- Enhances precision in feeding operations, improving product consistency.

- Lowers operational costs through energy-efficient frequency control.

- Simplifies integration and maintenance with flexible mounting options.

- Supports diverse production environments, from pharmaceuticals to pet food.

- Increases operational reliability with compliance to industry standards.

- Applications

- Food, Fine chemical, Feed, Recycling, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Pet food kibbles, Rubber compounds, Nutritional supplements, Pharmaceutical tablets, Snack foods, Color masterbatches, Chemical additives, Plastic granules, Milk powder, Fish pellets, Animal feed pellets, Processed minerals, Pharmaceutical compounds, Laundry detergents, Recycled plastic flakes

- Steps before

- Dosing, Mixing, Extrusion

- Steps after

- Pelletizing, Packaging, Inspection

- Input ingredients

- Output ingredients

- Market info

- Voltage Compatibility

- 1 phase or 3 phase

- Controller Type

- Frequency controller

- Installation Type

- Closed housing / DIN-rail mounting

- Feeder Compatibility

- Volumetric / Gravimetric feeders

- Wiring

- Fully wired

- Frequency controller type

- 1 phase / 3 phase

- Mounting type

- DIN-rail / Enclosure on feeder

- Feeder type compatibility

- Volumetric / Gravimetric

- Installation type

- Fully wired

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact / Standard

- Control panel type

- Integrated / External

- Discharge method

- Electrical / Manual

- Mounting type

- DIN-rail / Cabinet

- Enclosure type

- Closed / Open

- Phase type

- 1 phase / 3 phase

- Control method

- Frequency controller

- Enclosure type

- Closed housing / DIN-rail mounting

- Cable management

- Fully wired

- Feeder type compatibility

- Volumetric / Gravimetric