Powder dosing for lab and galenics

Ideal for precise dosing needs, this compact lab device streamlines powder filling processes, ensuring accurate sample production and testing in research and development stages.

Precisely Doses and Fills Pharmaceutical Powders

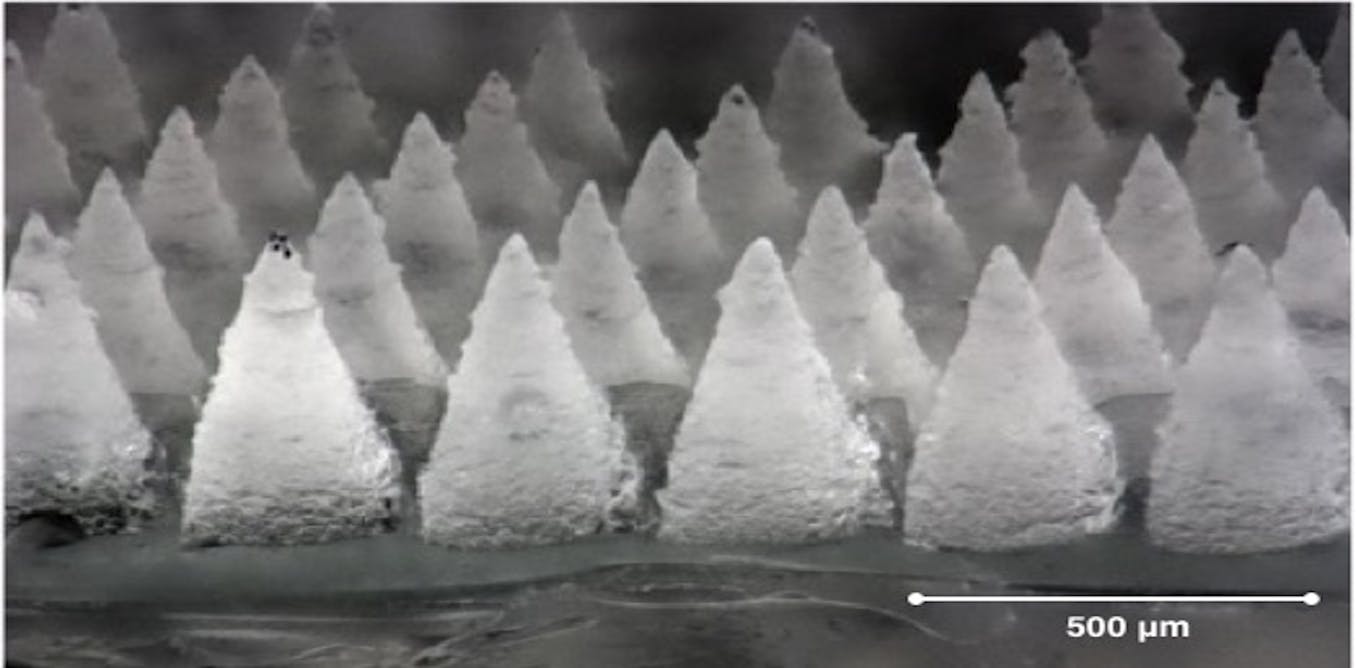

The Tamping Pin TT from Harro Höfliger offers precise manual dosing and filling solutions for pharmaceutical powders, critical in labs and R&D environments. This compact, hand-held device is perfect for developing capsule formulations using a metering disk to achieve exact fill quantities. Its versatility allows you to handle a variety of powder types—like active pharmaceutical ingredients, powder blends, and pellets—at a dosing volume of 50 to 1,385 mm³ and a dosing range of 25 to 690 mg, suitable for a range of end-products including capsules, vials, and microneedle patches.

Integrated as a lab table unit, it provides approximately five dosages per minute, making it ideal for sampling and testing minimal quantities. The equipment supports different filling methods, like tamping pin, dosator, and drum filling, ensuring compatibility with varied powder properties. Its construction from durable materials ensures longevity and ease of maintenance, making it an essential tool for pharmaceutical manufacturers and CDMOs focused on developing innovative drug delivery systems like transdermal patches, inhalation capsules, and oral tablets.

Benefits

- Enhances development efficiency with precise powder dosing for small-scale testing.

- Facilitates flexible research with multiple filling methods for varied applications.

- Improves accuracy and reliability in trial production with reproducible, comparable dosages.

- Minimizes material waste through precise micro-dosing capabilities.

- Supports cost-effective innovation in R&D with rapid configuration adjustments for different powder types.

- Applications

- Pellets, Oral delivery systems, Diagnostic products, Active ingredients, Liquids, Inhalation products, Pharmaceutical powder, Tablets, Transdermal, Capsules, Pharmaceutical devices, Microneedles, Surgical sutures, Powder blends, Mini tablets, Skin care, Medical, Wound, Eye care

- End products

- Wound healing ointments, Liquid-filled capsules, Vial composites, Active pharmaceutical ingredients (apis), Surgical suture packets, Microneedle patches, Transdermal patches, Inhalation capsules, Capsule formulations, Diagnostic kits, Skin care creams, Oral tablets, Eye drop solutions

- Steps before

- Grinding, Powder Blending

- Steps after

- Capsule Filling, Packaging, Quality Control

- Input ingredients

- pharmaceutical powders, powder quantities, capsules, pellets, tablets, mini tablets, powder blends, active ingredients, liquids

- Output ingredients

- filled capsules, vials, stainless steel vials, separate containers

- Market info

- Harro Hoefliger is known for its expertise in manufacturing custom, engineered-to-order packaging and production equipment, particularly for the pharmaceutical, healthcare, consumer goods, and chemical industries, with a reputation for precision, innovation, and quality engineering solutions.

- Dosing volume

- 50 - 1, 385 mm³

- Dosing range

- 25 - 690 mg

- Particle size

- 60 - 150 µm

- Output

- approx. 5 dosages/min.

- Fill volume

- Dependent on hole size and disk height

- Automation

- Manual

- Working mechanism

- Tamping pin dosing

- Batch vs. continuous operation

- Batch

- Automation level

- Manual

- Changeover capability

- Retooling for dosing roller or tamping pin

- Cleaning method

- Manual cleaning

- Dosing flexibility

- Micro-dosing, multiple methods (membrane, dosator, drum)

- Output rate

- Approx. 5 dosages/min

- Particle size compatibility

- 60 - 150 µm

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Final products

- Capsules, Vials, Stainless steel vials, Separate containers

- Compact footprint

- Lab table unit

- Control panel type

- Manual operation

- Discharge method

- Metering disk

- Machine portability

- Hand-held device

- Compact footprint

- Yes

- Control panel type

- Manual

- Discharge method

- Manual

- Dosing type

- Volumetric / Tamping pin