Semi-automatic production solution for in-vitro diagnostic products

Simplify precision tasks in molecular and immunodiagnostics while reducing manual errors with this ergonomic platform, perfect for improving product consistency and staff efficiency in clinical settings.

Automates Liquid Dispensing and Assembly for Diagnostics

The TM 05 from Rychiger is a versatile, semi-automated platform designed to streamline the production of in-vitro diagnostic kits and reagents. It excels in automating tasks like liquid dispensing, pipetting, and assembly, effectively reducing manual labor while ensuring precision and consistency. Suitable for applications in molecular and immunodiagnostics, the TM 05 enables production of end-products such as PCR kits, ELISA kits, and lyophilized enzyme beads.

Operating in a stand-alone mode, it can process up to six units per minute with a flexible footprint of 1.5 square meters, integrating seamlessly into laboratory and workshop-style environments. The equipment offers ergonomic access to all components, facilitating easy operation and maintenance. Designed for scalability, the TM 05 helps rapidly-growing startups and contractors maximize productivity and maintain high-quality standards. It is equipped to handle both liquids and solids, with optional sealing and tagging capabilities to match specific production requirements.

Benefits

- Enhances productivity with semi-automated processes, reducing manual workload.

- Ensures consistent product quality with precise liquid dispensing and assembly.

- Scalable design supports growth from small-batch to larger production capacities.

- Ergonomic setup minimizes operator strain and improves accessibility.

- Customizable configurations accommodate diverse diagnostic product requirements.

- Applications

- Liquid reagents, Molecular diagnostics, Lyophilized products, Diagnostic kits, In-vitro diagnostics, Clinical chemistry, Immunodiagnostics, Diagnostic reagents

- End products

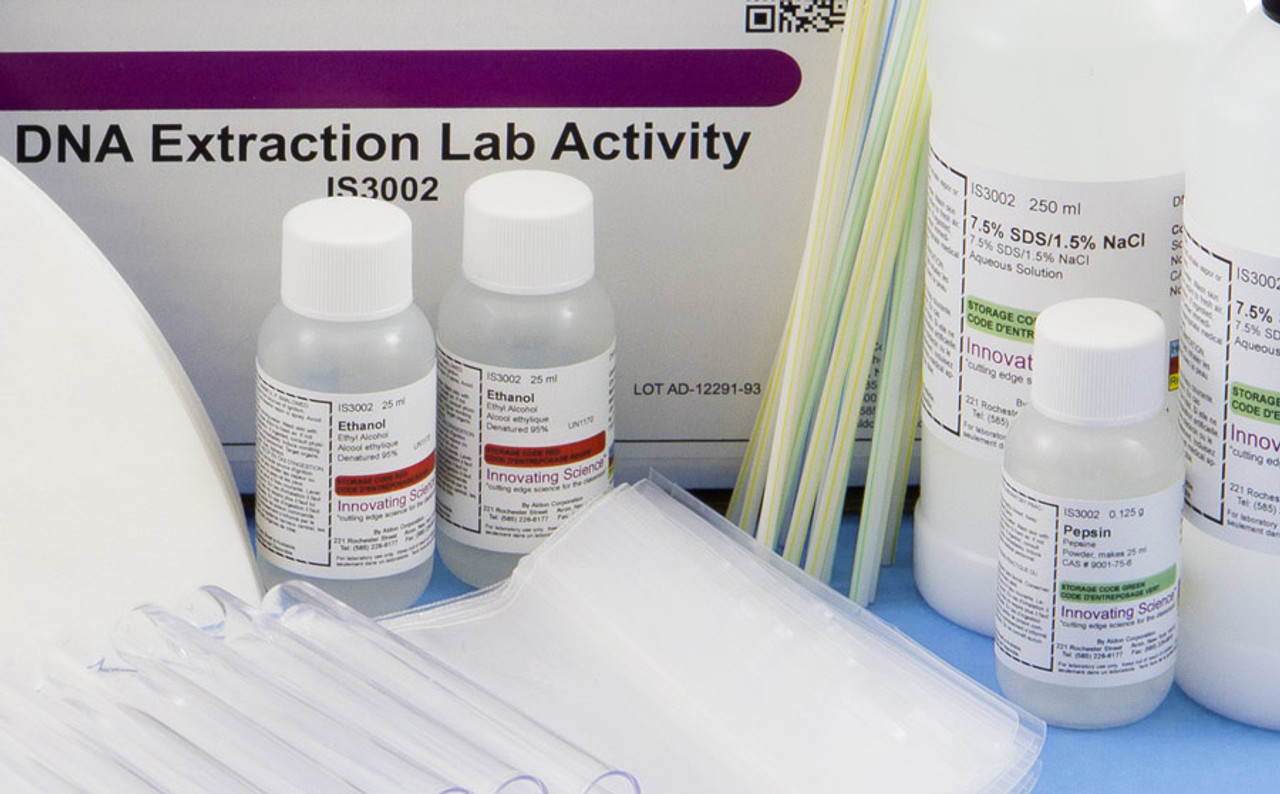

- Pre-packaged chromogen solutions, Dna extraction kits, Rna isolation reagents, Magnetic bead separation kits, Buffer solutions for assays, Hormone assay kits, Master mix for qpcr, Reagent kits for pcr testing, Taq polymerase solutions, Antibody testing kits, Lysis reagent kits, Lyophilized enzyme beads, Sepharose bead suspensions, Elisa kits

- Steps before

- Dosing, Pipetting, Assembly

- Steps after

- Quality Controls, Tagging, Labeling, Packing

- Input ingredients

- liquid reagents, viscous reagents, agarose/Sepharose liquids, lysis fluids, magnetic beads, latex beads, master mixes, Taq™, Oligos, fluorescent samples, chromogens, lyophilized products, abrasive powders, lyophilized beads

- Output ingredients

- in-vitro diagnostic products, clinical trial samples, semi-automated processes

- Market info

- Rychiger is known for engineering high-precision filling and sealing machines for the food and medical industries, offering customized, innovative automation solutions, with a strong reputation for reliability and exceptional engineering expertise in the packaging sector.

- Output/min

- 6

- Output/h

- 360

- Unit height

- Up to 120 mm

- Outer unit diameter

- Up to 160 mm

- Number of lanes

- 1

- Size (LxWxH)

- 1 - 1.5 x 1 x 2 m

- Weight

- 300 kg

- Connected load

- 3 x 400 V + Pe / 50 Hz

- Rated power

- 5 kW

- Compressed air

- a≥ 5 bar, 55 Nm³/h

- Volume

- 5 l/min

- Cleanroom Classification

- ISO 7/8

- Footprint

- 1.5m²

- Ergonomics

- Superior

- Automation level

- Semi-automatic

- Process flexibility

- High

- Ergonomic design

- Yes

- Batch capability

- Lab-scale to small batches

- Process validation

- Fully validated

- Reproducibility

- High

- Cleaning method

- Easy access for cleaning

- Application scalability

- Gradual automation

- Accessibility of components

- Maximum accessibility

- Footprint

- 1.5m²

- ISO Class Cleanroom Compatibility

- ISO Class 7/8

- Footprint

- 1 - 1.5 x 1 x 2 m

- Output capacity

- 6 containers/min

- Energy efficiency

- 5 kW power

- ISO Certification

- ISO 7 / ISO 8

- Machine footprint

- 1.5 m²

- Unit dimensions (LxWxH)

- 1 - 1.5 x 1 x 2 m

- Weight

- 300 kg

- Number of lanes

- 1

- Outer unit diameter

- Up to 160 mm

- Unit height

- Up to 120 mm

- Ergonomic Design

- Superior ergonomics for accessibility

- Process Flexibility

- Wide range of process technologies

- Platform Design

- Stand-alone unit configuration

- Installation Ease

- Roll to site and connect