Filling and closing system for cartridges

Enhance your cartridge production with precise filling and closing technology designed to ensure high process reliability and gentle handling for sensitive liquid medications.

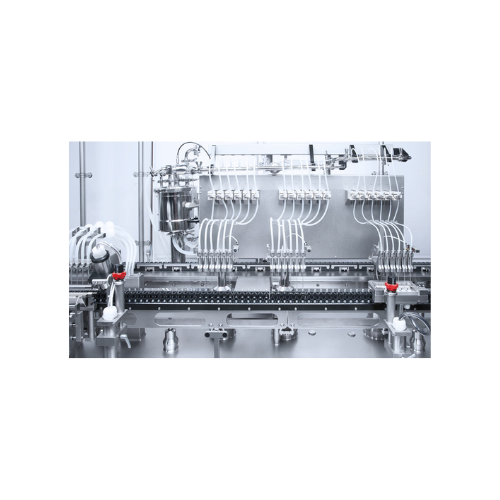

Fills and Closes Cartridges with Precision

The KFM Series from Bausch+Ströbel consists of advanced cartridge filling and closing machines engineered specifically for the pharmaceutical and biotech industries. This series is designed to accommodate intermittent-motion rotary and continuous linear operations, offering versatility in your production environment. The KFM Series addresses the need for precision and reliability in liquid formulations, effectively preventing contamination through a unique container transport system that eliminates glass-to-glass contact.

The machines are equipped to handle a range of applications, including the filling of insulin cartridges, vaccines, and monoclonal antibodies. With capacities reaching up to 36,000 items per hour, these machines support high-throughput operations while maintaining precision in dosing, with options for rotary piston pumps, peristaltic pumps, or time-pressure dosing systems. Fully integrating with upstream sterilization tunnels and downstream labeling machines, the KFM Series provides seamless automation across your production line.

The machines comply with GMP and FDA standards, ensuring regulatory compliance in all pharmaceutical applications. They also feature SIP/CIP-compatible dosing components, facilitating easy cleaning and maintenance, thus reducing downtime. For environments requiring strict contamination control, optional RABS and cleanroom isolators are available, along with automation-friendly PLC controls for enhanced process management.

Benefits

- Ensures product purity and consistency with precise filling and closing operations.

- Minimizes risk of contamination through specialized glass-free transport.

- Enhances production flexibility with interchangeable dosing systems.

- Supports high throughput, meeting demands of large-scale operations.

- Simplifies cleaning and reduces downtime with CIP/SIP compatibility.

- Applications

- Biopharmaceuticals, Cartridges, Liquid formulations, Pharmaceuticals

- End products

- Biologics in cartridge format, Monoclonal antibodies in cartridges, Injectable antibiotics cartridges, Hormone replacement therapy cartridges, Insulin cartridges, Vaccines in cartridge form, Liquid pain relief medication cartridges, Prefilled syringes with liquid medication

- Steps before

- Sterilizing tunnel, Upstream processing

- Steps after

- Closing with crimp caps, Labeling, Downstream processing

- Input ingredients

- cartridges, plunger stoppers, liquid products, dosing components, gas for flushing, mixing beads

- Output ingredients

- filled cartridges, sealed cartridges, crimp caps with rubber seal

- Market info

- Bausch Stroebel specializes in manufacturing high-quality pharmaceutical packaging and processing machinery, renowned for their precision, reliability, and innovation in filling and packaging lines for the pharmaceutical industry. They are respected for tailored solutions and advanced engineering.

- Output

- up to 36, 000 items/h

- Container diameter

- 7 - 14 mm

- Container height

- 40 - 90 mm

- Filling method

- Rotary piston pump / peristaltic pumps / time-pressure dosing

- Cleanroom compatibility

- Cleanroom isolator / RABS

- CIP/SIP compatibility

- SIP/CIP-compatible dosing components

- Automation

- Centralized operation

- Container transport

- Without glass-to-glass contact

- Gas-flushing stations

- Available

- Process reliability

- High

- Plunger stopper insertion

- From below

- Hopper options

- Various supply hoppers

- Working Mechanism

- Rotary and Intermittent-Motion Linear

- Integrated Steps

- Prefilling and Final Filling

- Batch vs. Continuous Operation

- Intermittent and Continuous

- CIP Principles

- CIP/SIP-Compatible Dosing Components

- Process Reliability

- High

- Container Transport

- Individual Glass-to-Glass Contact-Free

- Flexible Dosing Technology

- Rotary Piston, Peristaltic Pumps, Time-Pressure System

- Automation Level

- Centralized Operation

- Cleaning Method

- CIP/SIP

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Container diameter range

- 7 - 14 mm

- Container height range

- 40 - 90 mm

- Discharge method

- Crimp caps with rubber seal

- Operation method

- Intermittent-motion rotary and linear

- Transport system

- Individual, glass-to-glass contact-free

- Dosing system options

- Rotary piston, peristaltic, time-pressure

- Container transport system

- Individual gentle transport

- Closure options

- Crimp caps with rubber seal

- Sterilization and cleaning

- SIP/CIP compatible

- Barrier systems

- RABS, cleanroom isolator

- Optional extras

- Insertion of mixing beads, gas-flushing stations

- HMI or control panel integration

- Centralized operation

- Vision system compatibility

- Cleanroom compatible

- Output range

- KFM4008 to KFM12024, up to 36, 000 items/h