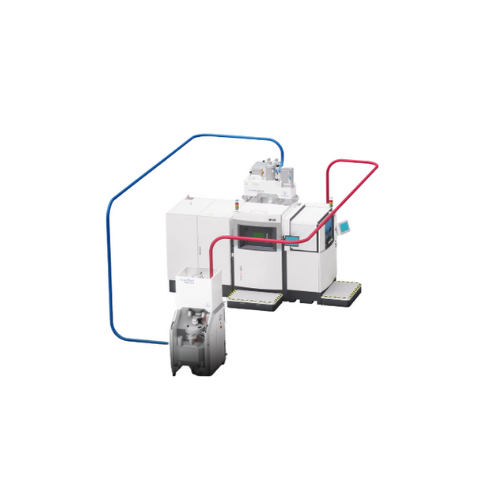

Closed powder handling loop for Eos metal Am printers

Effortlessly manage metal 3D printing powders with a solution that seamlessly integrates into your production line, ensuring precise dosing, efficient sieving, and contamination-free loading for enhanced additive manufacturing performance.

Automates Powder Handling for 3D Printing

The EOS Edition Powder Handling System for EOS M 290, M 300, and M 400 3D printers, developed in collaboration with Volkmann, revolutionizes metal additive manufacturing. This system excels in automating the entire powder management cycle, including conveying, vacuuming, cleaning, sieving, and loading, ensuring precise handling of 3D printing powders. It integrates seamlessly with existing setups, supporting a production cell of up to six printers, making it ideal for aerospace, automotive, and medical applications. The PowTReX component consolidates multiple functions, such as impurity removal and optimized dosing, while the vLoader 250 ensures continuous, inert gas-protected powder supply. Optional features like vacuum drying and flexible scalability enhance operational efficiency and product quality. The system is constructed to accommodate rigorous industrial demands, offering durability and reliability in continuous production environments.

Benefits

- Enhances production efficiency with fully automated powder handling.

- Minimizes contamination risks through closed-loop system design.

- Supports scalable integration, accommodating up to six printers.

- Reduces operational disruptions with continuous powder supply.

- Improves product quality by maintaining stable powder moisture levels with optional vacuum drying.

- Applications

- Metal powders, 3d printing powders, Additive manufacturing materials

- End products

- Metal 3d printed automotive parts, Metal 3d printed aerospace components, Metal 3d printed medical implants, Metal 3d printed tooling and molds, Metal 3d printed prototypes

- Steps before

- Powder Preparation, Material Handling, Powder Sieving, Impurity Removal

- Steps after

- 3D Printing, Powder Recycling, Component Drying, Printer Loading

- Input ingredients

- metal powder, unpacking station, setup station, 3D printer build frame

- Output ingredients

- cleaned metal powder, sieved metal powder, constant powder supply, dried metal powder

- Market info

- Volkmann is known for manufacturing vacuum conveying systems, specializing in pneumatic conveying of bulk materials. Their reputation for innovative and reliable equipment solutions in various industries positions them as a trusted provider for engineered-to-order material handling systems.

- Automation

- Fully automatic

- Distance for powder transport

- Up to 30 meters

- Vibration type

- Mechanical and ultrasonic

- Integration with 3D Printers

- Up to 6 Printers

- Handling process

- Pre- and post-processing

- Powder processing capability

- All common metal powders

- Screening size

- Removes impurities and agglomerates

- Drying option

- Vacuum drying with inert gas

- Inert gas usage

- Argon or nitrogen

- Vibration dampening

- Vibration dampers and flexible hose sleeves

- Automation level

- Fully automated

- Cleaning method

- Manual / CIP

- Batch vs. continuous operation

- Continuous

- Powder handling method

- Vacuum conveying

- Metal powder compatibility

- All common metal powders

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Corrosive resistance

- High, suitable for AM materials

- Abrasion resistance

- High, suitable for metal powders

- Compact footprint

- Integrated system

- Control panel type

- PLC-controlled

- Discharge method

- Vacuum conveyor

- Control panel type

- HMI / PLC interface

- Integration possibilities

- Multiple 3D printers

- EOS M 290,M 300,M 400

- Footprint size

- Compact / modular design

- Automation level

- Fully automated

- Scalability

- Upgradable up to six 3D printers

- Powder handling

- Closed loop system

- System adaptation

- Compatible with existing systems

- Modular devices

- PowTReX, vHub 250, vLoader 250