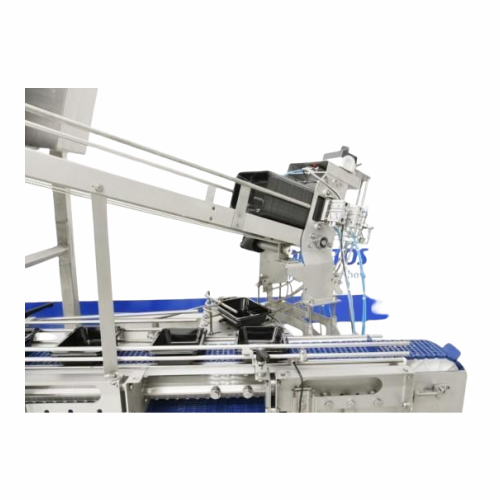

Tray handling equipment for food packaging

Optimize your food production with adaptable tray handling units that streamline dispensing, packing, and sealing processes, ensuring your ready-to-eat meals and packaged foods maintain quality and hygiene efficiently.

Dispenses, Covers, and Seals Ready Meal Trays

The Finntray series by Kometos provides comprehensive tray handling solutions tailored for the food processing and packaging industry. This equipment specializes in dispensing, covering, and sealing trays for ready meals, soups, salads, and more. It features flexible automation capabilities, allowing for seamless integration into high-speed production lines. With a capacity of up to 140 trays per minute, the Tray Dispensers efficiently manage aluminum, cardboard, or plastic trays. These units include pneumatic and electric actuation systems, while the covering machines utilize servo motor technology for precise lid application. The equipment is PLC-controlled with a Siemens S7 interface, ensuring user-friendly operation and minimal manual intervention. Constructed to meet stringent hygiene standards, these machines are easy to clean and maintain, supporting CIP systems for contamination-free processing. Optional customization and engineering support ensure these units can fit diverse production requirements, making them a versatile choice for enhancing packaging efficiency.

Benefits

- Increases production line efficiency by minimizing manual labor through high-speed automatic operations.

- Adapts quickly to product changes, supporting diverse meal types and seasonal demands.

- Ensures food safety with compliance to strict hygiene standards for easy cleaning and maintenance.

- Reduces production downtime with reliable actuator systems and prompt maintenance support.

- Integrates seamlessly into existing workflows with flexible automation and customizable configurations.

- Applications

- Soups, Salads, Ready meal portions, Porridge, Lasagnas, Pastas, Ready-to-eat meals

- End products

- Instant oatmeal, Chunky vegetable soup, Chicken alfredo pasta, Beef stew, Quinoa salad, Creamy tomato soup, Cheese tortellini, Vegetable stir-fry, Vegetable lasagna, Macaroni and cheese, Greek salad, Chicken caesar salad, Spaghetti bolognese, Caesar salad, Minestrone soup

- Steps before

- Product preparation, Tray loading, Material sorting

- Steps after

- Sealing, Labelling, Packing, Storage

- Input ingredients

- aluminum trays, cardboard trays, plastic trays, ready meal portions, soups, salads, pastas, lasagnas, porridge

- Output ingredients

- packaged ready-to-eat meals, sealed trays, dosed food portions

- Market info

- Kometos is known for manufacturing modular and mobile food processing facilities and equipment, offering innovative and tailored solutions for the food industry. Their expertise lies in efficiency, hygiene, and customization, enhancing clients' production capabilities.

- Speed

- 25–140 trays/min

- Capacity

- 1500–3000 trays/hour

- Tray size

- Max 280 x 360 mm

- Actuator

- Pneumatic / Electric

- Control system

- Plc Kometos / Siemens S7

- Power source

- Compressed air / Electric

- Automation

- Automatic feeding conveyor

- Adjustment

- Change tray size without tools

- Conveyor

- 1 pc / 2 pcs

- Track height

- 900 mm ± 50 mm

- Buffer magazine for lids

- Approx. 600 mm

- Capacity (Weight)

- 400 gr. / 700 gr. max 25–50 trays/min

- Actuator

- Electric servo motor / Pneumatic

- Accessories

- Shields and covers with safety limit switches

- Automation level

- Manual / PLC / Siemens S7

- Tray Capacity

- 25–140 trays/min

- Tray Size Flexibility

- Max. 280 x 360 mm

- Technology Integration

- Tray Dispenser / Covering Machine

- Changeover Flexibility

- Toolless Tray Size Change

- Handling Mechanism

- Pneumatic / Electric

- Operation Type

- Inline Tray Handling

- Cleaning Method

- Manual Easy-Clean Design

- Density/particle size

- Cardboard, plastic, aluminium trays

- Tray material

- Cardboard / plastic / aluminum

- Machine footprint

- Compact, adaptable to production line

- Tray size adaptability

- Max Tray Size

- Number of lines

- Single/Double-line configurations

- Tray handling speed

- 25 - 140 trays/min

- Control panel type

- PLC Kometos / Siemens S7 with colour touch-screen

- Inlet method

- Conveyor / Pusher

- Track height

- 900 mm ± 50 mm

- Control panel type

- Colour touch-screen

- Integration possibilities

- PLC Kometos / Siemens S7

- Tray Size Adjustability

- Change tray size without tools

- Expansion Capability

- Automatic feeding conveyor for tray stack

- Actuator type

- Pneumatic / electric