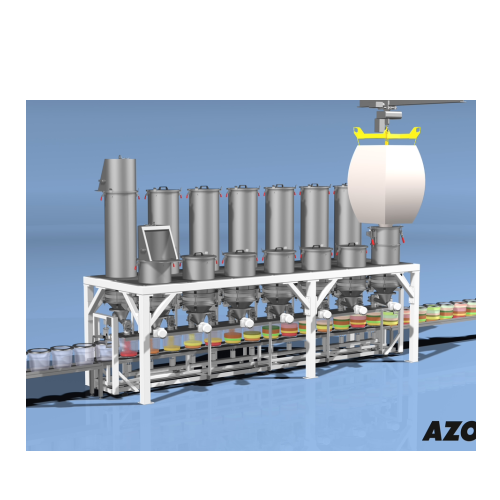

Automatic minor components weighing system

Streamline precision in your production by automating the weighing of minor and micro components, minimizing errors and enhancing efficiency for critical formulations.

Automates Weighing and Dosing of Minor Components

The AZO COMPONENTER® Step is a cutting-edge solution from AZO for automating the precise weighing and dosing of minor and micro components. Designed for the food, pharmaceutical, chemical, and plastics industries, this system tackles the challenges of manual weighing by ensuring gram-level accuracy and reducing contamination through rigorous batch separation. Components such as pigments, APIs, flavor enhancers, and other additives are automatically measured and tracked, integrating seamlessly into your production line. Utilizing a two-tiered system, materials are stored and identified in the upper level before transfer to target containers below, minimizing cross-contamination risks and improving throughput rates. The system supports continuous, high-speed operations, fully automating processes to meet stringent hygiene and safety requirements. Configurations can accommodate various materials and product alignments, ensuring alignment with your specific production needs. Additionally, the robust tracking technology enables complete traceability for compliance with industry standards and regulations.

Benefits

- Enhances product safety and consistency through precise component dosing and rigorous batch separation.

- Increases efficiency by minimizing manual processes, reducing labor costs and operator fatigue.

- Ensures compliance with stringent hygiene and safety standards across various industries.

- Facilitates flexible production planning with scalable module expansion and high throughput rates.

- Provides complete traceability of all processed components, improving quality assurance and regulatory compliance.

- Applications

- Food, Plastics, Chemicals, Pharmaceuticals

- End products

- Flavor enhancers, Additives for polymers, Active pharmaceutical ingredients (apis), Color additives, Chemical compounds, Plastic colorants, Pigment blends

- Steps before

- Purification, Drying, Grinding, Material Identification, Batch Preparation

- Steps after

- Quality Control, Mixing, Blending, Tablet Pressing, Packaging

- Input ingredients

- pigments, colourings, flavouring agents, additives, active agents, micro quantities, raw materials

- Output ingredients

- dosed components, weighed components, target containers with recipe-compliant components

- Market info

- AZO is renowned for designing and manufacturing automated bulk material handling systems, specializing in mixer feeding, ingredient automation, and process control, known for their reliability and tailored solutions in the food, pharmaceuticals, and chemical industries.

- Automation

- Fully automatic

- Batch separation

- Rigorous

- Accuracy

- Gram accuracy

- Capacity

- High throughput rates

- Cycle time

- Maximized by simultaneous weighing

- Container tracking

- Identification technology

- Dosing type

- Simultaneous weighing

- Dosing mechanism

- Dosing screws and vibration

- Process steps reproducibility

- Yes

- Filling method

- Pneumatic filling

- Material traceability

- Barcode identification

- Automation level

- Fully automatic

- Batch vs. continuous operation

- Batch

- Changeover time

- Minimal with modular capability

- Cleaning method

- Reduced cleaning required

- Tracking and tracing

- Yes, with barcoding

- Cleanability

- Compliant with hygiene requirements

- Density/particle size

- Able to handle pigments, colourings, agents

- Corrosive resistance (e.g. acids)

- Suitable for food, pharmaceuticals, chemicals

- Industry application

- Food, pharmaceuticals, chemicals, plastics

- Hygiene Standards

- Strict adherence

- Feed method

- Pneumatic, sacks, big bags

- Discharge method

- Pneumatic drive

- Control panel type

- PLC-controlled

- Container type

- Target containers with liners

- Integration Possibilities

- Compatible with 3D scan and VR technology

- Control System

- Fully automatic with tracking and tracing

- Modular Expansion

- Expandable with further modules for flexibility

- Target Container Liners

- Option to provide liners for containers

- Dosing Method

- Dosing screws combined with vibration bottoms

- Barcode Identification

- Raw materials identified using barcode

- Filling Options

- Filled from sacks or big bags

- Pneumatic filling feasible

- Identification Technology

- Tracking of target containers throughout process

- Pneumatic Drive

- Positioning of containers below dosing points

- Batch Separation

- Vibrating chutes for accurate metering