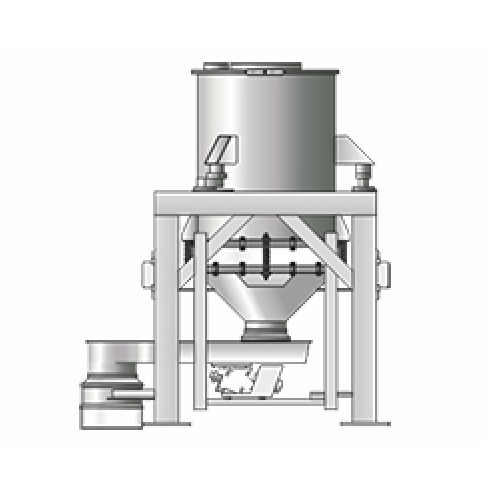

Loss-in-weight feeder for non-hygroscopic ingredients

Ensure precision in your dosing and weighing processes with this advanced feeder, ideal for handling non-hygroscopic solids like powders and granules, minimizing product degradation and maximizing linear conveyance accuracy across extensive feed rate ranges.

Precisely Doses and Weighs Solids and Powders

The SiloTray Loss-in-Weight Feeder from Solids Process Solutions (SPS) features a vibratory metering bin activator with variable speed vibration motors, designed to handle non-hygroscopic and non-sticky materials like pellets, powders, and flakes. This feeder excels in applications across aquafeed, pharmaceutical, chemical, and food industries, delivering precise, continuous dosing required for high-quality production outputs like fish pellets and pharmaceutical powders. The system ensures high weighing accuracy through its advanced weighing technology, while vibration amplitude feedback maintains steady flow over the entire feed rate range. With no stirring agitator, it minimizes ingredient degradation, integrating seamlessly into automated production lines. Built for efficient operation, the SiloTray is constructed from durable materials to withstand industrial conditions, offering options for customized configurations to meet specific operational needs.

Benefits

- Ensures high precision in dosing, minimizing waste and optimizing material usage.

- Maintains consistent material flow, reducing the risk of production line interruptions.

- Protects materials from degradation, preserving product quality.

- Integrates smoothly into automated systems, enhancing operational efficiency.

- Configurable for various applications, providing flexibility in multiple industries.

- Applications

- Food, Fine chemical, Feed, Recycling, Nutrition, Detergents, Compounding, Chemical, Pharma, Plastics, Minerals, Masterbatch, Aquafeed, Dairy, Petfood

- End products

- Liquid detergent base, Color masterbatch, Silicon dioxide powder, Pharmaceutical powders, Vitamin supplements, Dog food pellets, Gelatine capsules, Recycled plastic granules, Fish pellets, Polycarbonate granules, Composite materials, Cattle feed pellets, Lactose powder, Flour mix, Calcium carbonate powder

- Steps before

- Ingredient Preparation, Grinding, Drying

- Steps after

- Mixing, Extrusion, Packaging

- Input ingredients

- pellets, powders, flakes, fibers, chips, ingredients without hygroscopic characteristics, non-sticky ingredients, non-floodable ingredients

- Output ingredients

- accurately dosed materials, precisely metered ingredients, consistently distributed solids, linearly conveyed materials

- Market info

- Feed type

- Pellets / Powders / Flakes / Fibers / Chips

- Automation

- Variable speed vibration motors

- Vibration control

- Vibration amplitude feedback

- Accuracy

- High weighing accuracy

- Working mechanism

- Vibratory metering

- Automation level

- Variable speed vibration motors

- Cleaning method

- No stirring agitator

- Batch vs. continuous operation

- Continuous

- Vibration amplitude feedback

- Ensures linear conveyance

- Ingredient compatibility

- Non-hygroscopic, non-sticky, non-floodable

- Hygroscopic materials

- Not suitable

- Sticky materials

- Not suitable

- Floodable materials

- Not suitable

- Non-degradable materials

- Suitable

- Particle form

- Pellets / Powders / Flakes / Fibers / Chips

- Discharge method

- Vibratory

- Compact footprint

- Yes

- Integration possibilities

- Variable speed vibration motors

- Vibratory motor

- Variable speed

- Feedback system

- Vibration amplitude feedback