Blending silo for poorly flowing bulk material

Enhance your bulk material processing with a blending solution that ensures uniform mixing from multiple heights, tackling the challenges of poorly flowing materials with ease.

Ensures Homogeneous Blending of Bulk Materials

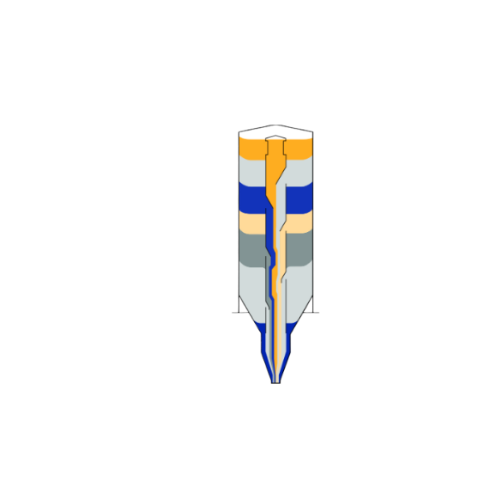

The Centro-Blend ZSD from Zeppelin Systems offers an efficient solution for blending various bulk materials across industries such as plastics, rubber, and food processing. The system uses a central blending pipe with multiple intake openings equipped with deflector plates. This design ensures equal draw from multiple heights within the silo, resulting in uniform, homogenous mixing of poorly flowing materials. Ideal for producing plastic pellets, rubber compounds, and food powders, the Centro-Blend ZSD can handle continuous and automated operations with high capacity. Its flat deflector plates prevent dead space and product assembly, promoting consistent mass flow. Designed for easy integration, it offers reliable performance for automated production lines and does not compromise on material integrity thanks to its robust construction.

Benefits

- Achieves uniform blending, enhancing product quality and consistency.

- Seamlessly integrates into automated production lines, increasing operational efficiency.

- Minimizes material waste with dead space elimination.

- Supports high-capacity operations for increased throughput.

- Durable construction ensures long-term reliability and reduced maintenance costs.

- Applications

- Chemicals, Fluff-tec, Performance materials, Food industry, Rubber and tire, Plastics, Dispersion paints

- End products

- High-performance composite materials, Rubber compounds, Tire treads, Emulsion paints, Chemical additives, Food powders, Flour mixes, Fluff pulp, Plastic pellets

- Steps before

- Material Conveying, Bulk Material Transport, Material Storage

- Steps after

- Material Dosing, Bulk Material Handling, Material Distribution

- Input ingredients

- bulk material, poorly flowing bulk material

- Output ingredients

- blended material

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Blending Method

- Central blending pipe

- Intake Design

- Multiple intake openings

- Deflector Plate Design

- Flat surfaces, varying sizes

- Integration

- Easy into processing

- Mass Flow

- Consistent design

- Automation

- No product assembly required

- Working mechanism

- Central blending pipe with multiple intake openings

- Flow integration

- Easy integration into processing

- Batch vs. continuous operation

- Continuous operation

- Mixing uniformity

- Consistent mass flow

- Automation level

- Potential for integration with PLC

- Cleaning method

- Manual cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Machine footprint

- Compact design

- Blending pipe structure

- Central pipe with multiple intake openings

- Deflector plate design

- Flat surfaces with varying sizes

- Discharge method

- Central blending pipe for uniform flow

- Control panel type

- PLC / Touchscreen HMI

- Integration possibilities

- Easy integration into processing

- Central blending pipe

- Multiple intake openings

- Deflector plates

- Weld-mounted, varying sizes

- Product discharge

- From blending pipe and outer ring