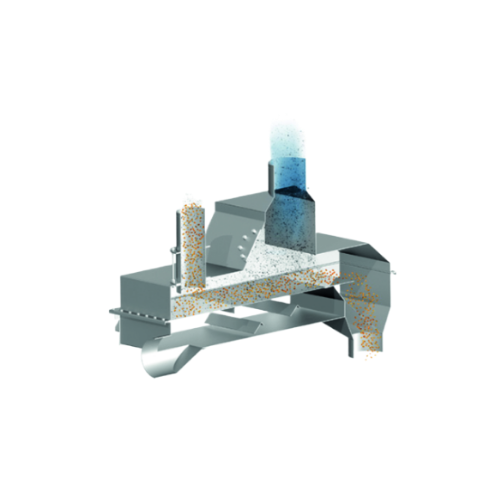

Vibratory pellet separator for dust and streamer removal

Achieve high-efficiency separation of dust and streamers from polymer granules with this compact vibratory pellet separator, enhancing product purity and process reliability in your production line.

Efficiently Separates Dust from Polymer Pellets

The VGS Separator ZSD from Zeppelin Systems is an essential component for plastics and chemical manufacturers focused on maintaining high purity levels in their products. This compact separator excels in efficiently removing fine dust particles and long streamers from polymer and plastic pellets. Leveraging a combination of vibration and flowing gas, the VGS Separator ensures consistent, high-efficiency separation throughout its operations.

Ideal for applications such as polypropylene, polyethylene, PVC, ABS, and specialty polymer blends, it handles gravimetric feeding with throughput up to 60 metric tons per hour. This versatile separator can be seamlessly integrated prior to packaging and loading processes. It features a straightforward design that simplifies installation and setup, eliminating the need for additional intake or discharge feeders. Additionally, the VGS Separator supports customization to match specific product and throughput requirements. Its durable construction suits continuous operations, accommodating both gravimetric and pneumatic feeding methods.

Benefits

- Enhances product purity by effectively eliminating dust and streamers from pellets.

- Increases production efficiency with continuous, high-throughput capabilities up to 60 metric tons per hour.

- Simplifies integration with compact design and minimal installation requirements.

- Improves operational flexibility, supporting both gravimetric and pneumatic feeding.

- Customizable to meet specific production needs, ensuring optimal performance for diverse applications.

- Applications

- Polymers, Complex plastics

- End products

- Specialty polymer blends, Polyethylene granules, High-performance engineering plastics, Nylon pellets, Abs plastic beads, Polycarbonate granules, Polypropylene pellets, Pet flakes, Pvc powder

- Steps before

- Grinding, Pulverizing, Pre-sorting

- Steps after

- Packing, Loading, Transporting

- Input ingredients

- pellets, polymers, complex plastics

- Output ingredients

- cleaned pellets, dust particles, streamers

- Market info

- Zeppelin Systems excels in designing and manufacturing high-quality bulk material handling and processing equipment. Renowned for its engineering expertise, the company serves industries including plastics, chemicals, and food, ensuring efficient, reliable, and innovative solutions tailored to customer needs.

- Separation efficiency

- Extremely high

- Feed type

- Pneumatic / Gravimetric

- Capacity

- Up to 60 metric tons/hour

- Cleaning method

- Gentle on products

- Design

- Compact

- Working Mechanism

- Gravimetric feeding with vibratory conveyor

- Integrated Steps

- Separation, Cleaning, Dosing

- Batch vs. Inline Flow

- Inline Continuous

- Automation Level

- Simple Dosing, High Efficiency

- Cleaning Method

- Gentle Cleaning

- Changeover Time

- Quick Setup and Installation

- Compatibility

- Polymers and complex plastics

- Compact footprint

- Yes

- Discharge method

- No intake or discharge feeders required

- Control panel type

- Integrated multiple screening