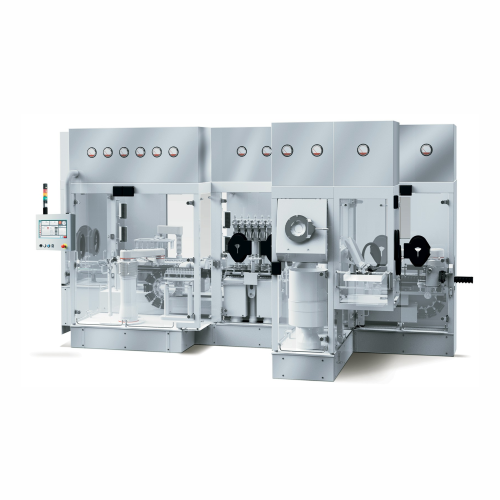

Filling and stoppering system for nested syringes

Ensure aseptic precision in syringe and vial preparation with a high-speed filling system designed for seamless integration and contamination prevention.

Fills and Stopper Nested Syringes and Vials

The Extrafill 10 by Marchesini Group is a high-speed, automated filling and stoppering machine specifically engineered for the pharmaceutical and biotech sectors. It excels in aseptic processing for liquid formulations, handling a range of container formats including nested syringes, vials, and cartridges. The machine employs a ten-head filling system with brushless motor-driven movements, ensuring precise dosing and reducing the risk of contamination thanks to its Balcony Style design, which promotes optimal airflow. Unique features such as the piston and peristaltic pump interchangeability, alongside in-process weight control, enhance operational flexibility. Capable of processing up to 36,000 syringes per hour, the Extrafill 10 integrates seamlessly into production lines with its denesting and detraying units, along with reject and recover systems for faulty containers. Compliance with GMP standards is ensured, with options for installation under LAF, RABS, or in isolator environments, offering a high degree of process control and contamination prevention. Additionally, the system facilitates efficient maintenance access and format changes, vital for minimizing downtime in high-demand environments.

Benefits

- Enhances production efficiency with high-speed processing up to 36,000 syringes per hour.

- Minimizes contamination risks through optimal airflow design and aseptic processing capabilities.

- Reduces operational downtime with easy format changes and maintenance access.

- Ensures precise dosing with adjustable weight control and interchangeable pump systems.

- Meets stringent pharmaceutical standards with compliance options for various controlled environments.

- Applications

- Liquid formulations, Syringes, Vials, Biopharmaceuticals, Cartridges, Pharmaceuticals

- End products

- Insulin prefilled syringes, Biotech protein formulations, Antibiotic vials, Saline syringes, Adrenaline auto-injectors, Monoclonal antibody solutions, Heparin cartridges, Growth hormone cartridges, Vaccine vials, Chemotherapy liquid doses

- Steps before

- Washing and Sterilizing, Air Cleaner and Blowing, Nested-Tray Preparation

- Steps after

- Visual Inspection, Syringe Re-nesting, Alu-capping, Packaging

- Input ingredients

- nested syringes, RTU vials, RTU cartridges, Nest/Tub, Nested-Trays, Tub/Nest

- Output ingredients

- filled syringes, filled vials, filled cartridges, stoppered containers, sealed products

- Market info

- Marchesini is renowned for manufacturing high-quality packaging machinery for the pharmaceutical and cosmetics industries, offering innovative, customized solutions with advanced automation and technology.

- Speed

- up to 36, 000 syringes/h

- Filling Heads

- 10

- Filling Volume

- 0.5 ml - 10 ml (syringes), 2R - 15R (vials), 1 ml - 5 ml (cartridges)

- Automation

- Brushless motors

- Weight Control

- 0 ÷ 100% Adjustable IPC

- Stopper Sorting System

- Innovative system to avoid jamming

- Sampling

- Dedicated unload lane

- Machine Installation

- Possible under LAF, open/closed RABS, or Isolator

- Container Rejection

- Single container rejection system

- Denesting/Detraying Unit

- Robotized for syringes and RTU vials

- Dosing Method

- Rotary Piston Pumps / Peristaltic Pumps

- Container Type

- Syringes, RTU vials, RTU cartridges

- Automation level

- Manual / PLC / SCADA

- Batch vs. continuous operation

- Batch / Inline Continuous

- Airflow Laminarity

- Perfect air flow laminarity over containers

- Wall installation arrangement

- Backside maintenance access

- Stopper sorting system

- Innovative to avoid jamming

- Changeover capability

- Easy switch between pump types

- Container rejection system

- Single container rejection

- Feeding system efficiency

- Sticky stoppers recovery system

- Installation flexibility

- Under LAF, open/closed RABS, Isolator

- Machine type

- Automatic High-speed Filling Machine

- Filling heads

- 10 filling heads

- Footprint

- Balcony Style Design

- Installation

- Possible Wall Installation

- Product formats

- Syringe, RTU vials, RTU cartridges

- Product types

- Liquid to very viscous gel

- Stopper sorting system

- Innovative system to avoid jamming

- Control type

- Brushless motors

- Rejection lane

- Single Container Rejection

- Sampling lane

- Dedicated unload lane for sampling

- Container diversion

- Integrated system for vial to alu-capping machine

- Integration possibilities

- No Glass-To-Glass connection to downstream machines

- Installation arrangement

- Wall Installation with backside maintenance

- Stopper sorting system

- Innovative system for simpler format change