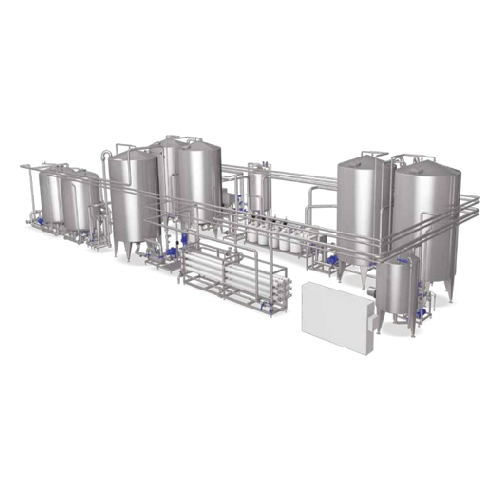

Industrial water disinfection system

Ensure the microbiological safety of liquids by utilizing an advanced water disinfection solution that leverages ozone, chlorine, and UV technologies for comprehensive pathogen elimination without altering taste or odor.

Delivers Precise Ozone Dosage for Water Disinfection

The EASY.Ozone from A Due S.p.A. is a sophisticated ozone dosing system designed for robust water disinfection across beverage production, food processing, and water treatment plants. Utilizing ozone’s potent oxidizing properties, this system guarantees effective sterilization of water, ensuring the safety and quality of end-products such as mineral water, fruit juices, plant-based beverages, and carbonated drinks. It features a stand-alone design with flexible installation options, including configurations with or without a contact tank for optimal ozone and water interaction. The system can adjust ozone concentration in proportion to water flow rate, temperature, and pH, ensuring precise disinfection tailored to specific processing needs. With a throughput capacity ranging from 10,000 to 100,000 liters per hour, EASY.Ozone supports continuous operation and easy integration into existing filling systems. Engineered for energy efficiency, it includes an optional water cooling feature for enhanced performance. The system is equipped with an automatic start and stop function, ozone destroyer, and environmental ozone detection for safe operations. Constructed from corrosion-resistant materials, it supports reliable long-term use with minimal maintenance, making it an ideal choice for industries requiring stringent purity standards.

Benefits

- Enhances product safety and quality with precise ozone disinfection, eliminating pathogens effectively.

- Supports high-volume operations with a processing capacity of up to 100,000 liters per hour.

- Reduces operational risks with automatic start-stop management and integrated ozone detection systems.

- Customizable dosing ensures tailored disinfection, adapting to specific water characteristics for optimal results.

- Lowers maintenance demands with corrosion-resistant construction and continuous operation capability.

- Applications

- Plant-based beverages, Milk, Non-alcoholic beer, Water treatment, Beverage production, Hard seltzers, Food processing, Fantasy drinks, Juices, Carbonated soft drinks, Flavored water

- End products

- Carbonated lemonade, Hard cranberry seltzer, Hard lime seltzer, Table water, Apple juice, Alcohol-free lager, Orange juice, Almond milk, Soy milk, Enhanced mineral water, Bottled spring water, Energy drinks, Fruit-flavored water, Herbal-infused sparkling water, Sparkling cola, Non-alcoholic malt beverage

- Steps before

- Filtration, Reverse Osmosis, Remineralization

- Steps after

- Bottling, Carbonation, Storage

- Input ingredients

- untreated water, Sodium Hypochlorite, Ozone, UV light, Chlorine

- Output ingredients

- disinfected water, reduced pathogens, residual chlorine, residual ozone

- Market info

- A Due is known for designing and manufacturing beverage processing equipment, specializing in water treatment, syrup preparation, and complete automation solutions for the beverage industry, with a strong reputation for innovation and quality engineering.

- Automation

- Fully automatic / semi-automatic

- Contact time

- 3–5 minutes

- Flowrate

- 10, 000 l/h to 100, 000 l/h

- UV dose

- 40–120 mJ/cm²

- UV lamp wavelength

- 253/254 nm

- Residual ozone quantity

- 0.2–1 ppm

- Residual chlorine control

- 1–5 PPM

- Sodium hypochlorite capacity

- 0.5–10 l/h

- Continuous operating time

- Up to 12, 000 hours

- Working mechanism

- Chlorine dosage, UV irradiation, Ozone dosage

- Integrated steps

- Water disinfection, contact tank, residual control

- Batch vs. continuous operation

- Continuous operation

- Automation level

- Manual / Fully automatic / Semi-automatic

- Cleaning method

- Not specified

- Energy efficiency

- Not specified

- Contact time

- Varies by system and application

- Corrosive resistance (e.g. acids)

- Stainless steel 316L

- Tank shape

- Contact tank

- UV Lamp length

- Continuous operating time up to 12, 000 hours

- Material of UV chamber

- 316L stainless steel

- Ozone system design

- Fully automatic, semi-automatic, with or without contact tank

- Flowrate for ozone and UV systems

- 10, 000 l/h to 100, 000 l/h

- Compact system for UV

- Suitable for continuous operation

- Control panel type

- Automatic / Semi-automatic

- Integration possibilities

- Inline systems, SCADA compatible

- Disinfection method options

- Chlorine, UV, Ozone

- Contact tank presence

- With or without tank

- Ozone dosage adjustment

- Proportional to water characteristics

- UV lamp brand compatibility

- Various international brands

- Ozone detection and destruction

- Equipped

- UV irradiation chamber material

- 316L stainless steel

- HMI integration

- Automatic start, stop management

- Cooling options for Ozonizer

- Water cooling available

- CIP support

- Available for hot CIP