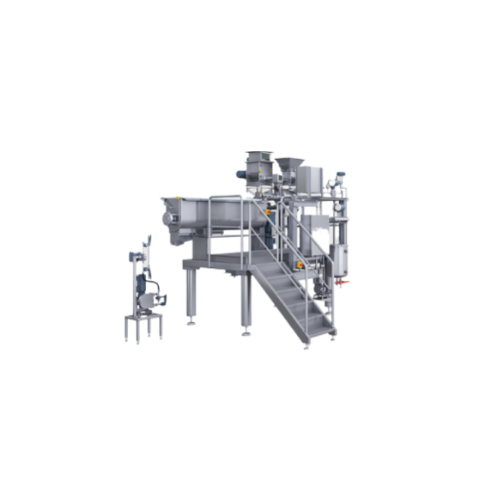

Automatic continuous mixer for dough preparation

Streamline your production line with a mixer that ensures precise dosing and thorough mixing of raw materials, optimizing dough quality for a broad range of food products.

Mixes and Doses Ingredients Continuously

The GRIM Continuous Dough Mixer, available in single and double vessel configurations, is designed by GEA to deliver precise and consistent dough mixing for the food industry. Its automatic dosing system efficiently measures and mixes flour, liquids, and micro ingredients, utilizing PLC control for precise operation. Ideal for pasta, snacks, and breakfast cereal production, it ensures superior dough quality with a mixing capacity ranging from 150 to 3000 kg/h. The mixer features a conical paddle shaft in a stainless-steel vessel for robust mixing, with easy access for maintenance due to its opening cover and safety switch. Integrated with upstream and downstream processes, it is customizable to fit your production needs, offering reliability and minimal energy consumption. The GRIM mixer stands out for its ability to enhance production efficiency while maintaining high standards of quality and safety compliance.

Benefits

- Enhances productivity with continuous, automated mixing.

- Optimizes ingredient use, reducing waste with precise dosing.

- Improves dough quality for better end-product texture and elasticity.

- Streamlines integration into existing production lines.

- Minimizes maintenance time with easy access design and safety features.

- Applications

- Dough, Snacks, Pasta, Fresh pasta, Breakfast cereals

- End products

- Spaghetti, Pizza dough, Granola bars, Tortellini, Potato chips, Corn puffs, Penne, Bread dough, Muesli, Ravioli, Pasta sheets, Fresh linguine

- Steps before

- Dosing, Weighing, Measuring

- Steps after

- Mixing, Kneading, Gluten Development, Quality Assurance

- Input ingredients

- flour, micro ingredients, liquids, water, eggs

- Output ingredients

- dough

- Market info

- GEA is known for its expertise in engineering innovative and sustainable equipment and solutions, focusing on sectors such as food, beverages, pharmaceuticals, and energy, with a reputation for quality, efficiency, and advanced technological applications in industrial processing.

- Capacity

- 150-1800 kg/h (single)

- 1200-3000 kg/h (double)

- Automation

- PLC-controlled

- Mixing time

- 12 minutes

- Dosing Type

- Automatic dosage (ponderal or volumetric)

- Shaft Type

- Shaft with paddles fixed by conical joint

- Material

- Stainless Steel

- Dosers Customization

- Customizable

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC-controlled

- Mixing time

- At least 12 minutes

- Dosage systems

- Automatic flour, micro ingredients, and liquids dosage

- Feeding system

- Stainless-steel terrace placement for discharge and feeding

- Shaft design

- Shaft with paddles fixed by a conical joint

- Safety features

- Safety switch on mixing vessel cover

- Customizability

- Customizable dosers according to desired program

- Corrosive resistance (e.g. acids)

- Yes

- Density/particle size

- 0.7–1.0 g/cm³

- Biological compatibility

- Suitable for food-grade materials

- Cleanability

- Stainless steel construction

- Dough Mixing

- Pasta, Snacks, Breakfast Cereals

- Vessel Type

- Single / Double

- Footprint

- Compact

- Construction Material

- Stainless Steel

- Discharge Method

- Terraced Feeding

- Mixing Vessel Access

- Opening Cover with Safety Switch

- Mixing Shaft Design

- Shaft with Conical Joint Paddles

- Customization of Dosers

- Yes

- Dosers Customization

- According to desired program

- Mixing Vessel Access

- Opening cover with safety switch

- Control System

- PLC-controlled