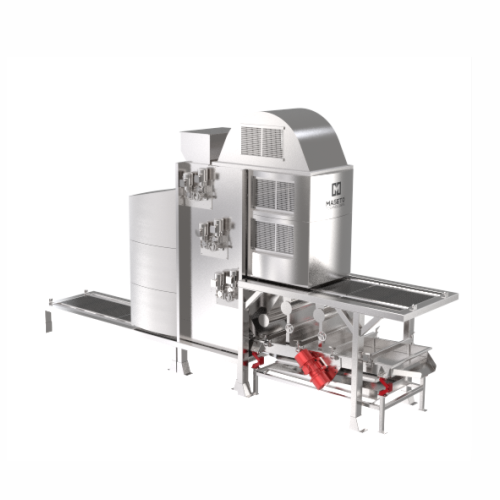

Industrial pistachio peeler

Efficiently remove the interior hull from pistachios with mechanical friction, ensuring high-quality output for blanched and roasted products in your nut processing line.

Detaches Pistachio Hulls via Mechanical Friction

The Maseto Pistachio Mechanical Friction Peeler efficiently removes the interior hull from pistachios, optimizing your nut processing operations. This equipment utilizes a multi-stage mechanical friction system with rollers to detach hulls, followed by compressed air for removal. Designed for nut processors and industrial food manufacturers, it’s ideal for producing peeled, blanched, and flavored pistachio snacks.

Handling between 500 to 3500 kg/h, it supports continuous high-speed operations. The optional washing stage enhances product appearance and reduces maintenance needs. Integrate this friction peeler into your line for streamlined automated processing. Engineered with robust materials for durability, it’s easily maintained and customizable for specific production requirements.

Benefits

- Maximizes efficiency by processing up to 3500 kg/h with continuous operation.

- Enhances product quality with optional washing for improved appearance.

- Reduces maintenance with streamlined mechanical friction and compressed air systems.

- Customizable integration ensures compatibility with existing processing lines.

- Decreases production costs with automated high-speed peeling.

- Applications

- Nuts, Pistachios, Snacks

- End products

- Blanched pistachios, Flavored pistachio snacks, Peeled pistachios, Roasted pistachios

- Steps before

- Blanching

- Steps after

- Washing, Whitening, Cleaning, Maintenance

- Input ingredients

- blanched pistachios

- Output ingredients

- peeled pistachios

- Market info

- Maseto is known for supplying industrial engineered-to-order (ETO) equipment, specializing in custom machinery solutions for various sectors. Their expertise lies in advanced engineering, innovation, and high-quality manufacturing, earning them a strong reputation for reliability and precision.

- Capacity

- 500 – 3500 kg/h

- Automation

- PLC-controlled

- Compressed Air Usage

- Required for hull removal

- Peeling Method

- Mechanical friction

- Cleaning Method

- Optional washing

- Process Phases

- Three to four phases

- Working mechanism

- Mechanical friction

- Integrated steps

- Blanching, peeling, air removal

- Batch vs. continuous operation

- Continuous inline

- Air incorporation control

- Compressed air system

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Abrasiveness

- Yes/No

- Foaming potential

- Low/Medium/High

- Heat sensitivity

- Low/Medium/High

- Container size and shape

- Variable

- Particle size

- Variable

- Product moisture content

- Low/Medium/High

- Shape

- Irregular/Uniform

- Discharge method

- Compressed air system

- Customization phase

- Fourth (washing)

- Material handling

- Four treatment phases

- Control panel type

- Touchscreen / Standard

- Integration possibilities

- Washing unit integration

- Optional feature

- Washing treatment

- Design flexibility

- Subject to change