Chestnut sorting and grading system

Optimize chestnut processing with advanced sorting technology that ensures precise size classification and defect detection, enhancing product quality and market readiness for your produce.

Sorts and Grades Chestnuts with Precision

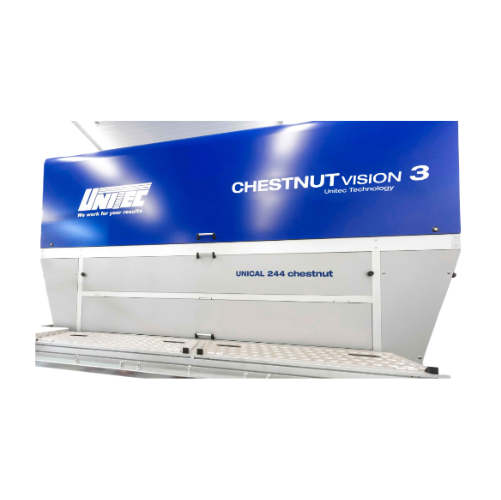

The Chestnut Vision 3, paired with the UNICAL 244 from UNITEC, delivers exceptional precision in sorting and grading for the food processing and agricultural industries. This equipment utilizes advanced vision systems to detect defects such as cracks, holes, and buds in chestnuts, categorizing them by size, form, and quality. It handles applications across fresh produce, bakery, and processing sectors, delivering end-products like roasted chestnuts, chestnut flour, and bakery fillings. With a high throughput capacity designed for continuous, automated operation, it seamlessly integrates into existing production lines. The system, built with durable materials, ensures reduced maintenance downtime and is supported by comprehensive engineering and customization options.

Benefits

- Enhances product quality by accurately sorting and grading chestnuts based on size and defects.

- Increases efficiency with continuous, automated operation, reducing reliance on manual labor.

- Integrates seamlessly with existing production lines, optimizing workflow and reducing setup time.

- Minimizes waste by precisely identifying unsuitable produce for repurposing or removal.

- Offers long-term cost savings through durable construction and reduced maintenance requirements.

- Applications

- Bakery sector, Fruits, Vegetables, Chestnuts, Processing industry

- End products

- Chestnut puree, Fruit salads, Chestnut flour, Processed chestnut snacks, Chestnut stuffing, Preserved fruits, Roasted chestnuts, Candied chestnuts, Vegetable mixes, Bakery fillings

- Steps before

- Harvesting, Cleaning, Calibrating

- Steps after

- Packing, Quality Control, Distribution

- Input ingredients

- chestnuts

- Output ingredients

- sorted chestnuts, fresh market chestnuts, bakery sector chestnuts, processing industry chestnuts

- Market info

- Automation

- PLC-controlled

- Sorting Accuracy

- High precision sorting

- Detection Type

- Vision system

- Product Capacity

- Varied by system configuration

- Handled Product Types

- Fresh market, bakery sector, processing industry

- Defects Detection

- Size, form, optical weight, external defects like cracks or holes

- Material Construction

- 100% Made in Italy components

- System Components

- Mechanical, electric, electronic, software, automation

- Quality Selection System

- Advanced quality selection

- Traceability

- Yes

- Efficiency

- Manpower optimization, cost savings

- Defect Types Detected

- Cracked, with holes, with bud

- Sorting Categories

- Size, form, quality classes

- Automation level

- PLC / SCADA

- Batch vs. continuous operation

- Continuous Inline

- Changeover time

- Minimal

- CIP/SIP

- Automated Cleaning

- Cleaning method

- CIP

- Energy efficiency

- Optimized consumption

- Air incorporation control

- Vision system

- Automation level

- Integrated automation

- Density/particle size

- 0.5–2.5 g/cm³

- Market Destination

- Fresh Market, Bakery Sector, Processing Industry

- Control panel type

- HMI touchscreen

- Integration possibilities

- PLC / SCADA systems

- Automation features

- Vision system integration

- Sorting parameters

- Size / Form / Quality

- Defect detection capability

- Cracked / Holes / Bud

- Made in

- Italy