Nut Packaging Equipment

Find production technology for packaging nuts, and connect directly with leading machine manufacturers worldwide.

When it comes to packaging nuts, high-quality packaging equipment is a must. Not only do they protect the nuts, but they also help to extend its shelf life. In order to achieve this, it's important to invest in the right nuts packaging equipment.

The Different Types of Nut Packaging Machines

There are different types of packaging machines available on the market. each with its own unique features and benefits. Some of the most common types of technologies to package nuts include:

- Fillers: These machines are designed to fill pouches or packaging bags with nuts, dried fruits, almonds, peanuts, pistachio, and even popcorn.

- Sealing machines: These machines seal the packaging bags once they are filled with the product.

- Automated packaging machines: These machines offer a high level of automation and are ideal for larger production volumes.

Key Features to Consider When Choosing The Right Packaging Solution For Your Nuts

When choosing a packaging machine, there are several key features to consider. These include:

- Type of packaging: There are many types of packaging available for snack foods, including pouches and packaging bags. Make sure you choose a machine that is compatible with the type of packaging you require.

- Product packaging requirements: Different products require different types of packaging. For example, cashews and almonds may require different packaging than peanuts. Make sure you choose a machine that is suitable for your specific product packaging requirements.

- Speed and capacity: The speed and capacity of the machine are important factors to consider, especially if you have a high-volume production. Look for a machine that can keep up with your production demands.

- Quality of packaging: High-quality packaging is important to protect the product and extend its shelf life. Look for a machine that can produce consistent, high-quality packaging.

- Maintenance requirements: Make sure you choose a machine that is easy to maintain and service, with readily available parts and support.

Choosing the right packaging equipment for your nuts is essential. Especially to ensure that your product arrives in top condition without contamination and damage. By keeping in mind all the consideration mentioned above, you can choose the right machine for your production needs. Whether you’re packaging cashews, almonds, peanuts, or other snack foods, investing in high-quality packaging solutions and filling machines can help to improve the overall quality of your product. And thus, maximizing overall profit.

What are you making?

Which nut packaging technology do you need?

Linear vibratory weigh filler for fragile food products

Achieve precise and gentle filling of fragile food products with ...

Linear weigh filler for accurate box packaging

Ensure precise weight-based filling for a variety of solid products, from d...

Vertical form, fill and seal packaging system for small bags

Maximize efficiency with small bag portioning for food and ...

Chestnut processing line for fresh market

Efficiently transform raw chestnuts into polished, fresh market-ready products w...

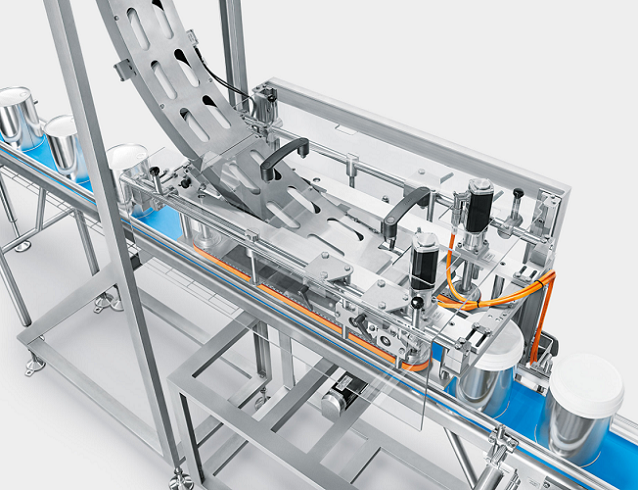

Single lane collator for packaging room

Streamline your packaging operations by efficiently collating, counting, and aligni...

Retractable spiral chute for bulk material handling

Enhance the integrity of your products by gently transferring bulk ma...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

Vertical pouch packaging system for food products

Achieve high-speed, precise packaging with our vertical pouch system, i...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

Vertical form fill sealer for high-speed packaging

Achieve consistent, high-speed packaging with flexible bag styles, per...

Single and dual lane sorters for fresh produce

Optimize your food processing line with precision defect detection and vers...

14 head multihead weigher for dry products

Achieve precise and rapid weighing for a variety of dry, free-flowing products ...

Semi-automatic case packer for chip bags

In small to medium scale production units, packing items manually can consume a lo...

Filling and weight checking machine for food cans

Making sure the right quantity of product is in the packaging can be a ...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Automatic bag folding solution for bulk packaging

Enhance your production line efficiency and product protection by integ...

Industrial Xl bag sealer for large pallet containers

Eliminate manual handling and ensure perfect seals for bulk packagin...

Gravity fed metal detector for dried foods

Ensure product purity and safety with metal detection between gravity feed hopp...

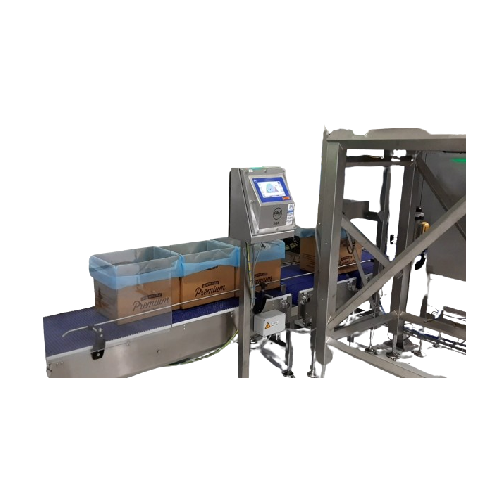

Checkweigher for high-care food environments

For facilities needing precision and hygiene, this high-care checkweigher ens...

Vertical dosing and filling solution for confectionery packaging

Optimize your confectionery and nutraceutical packaging...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

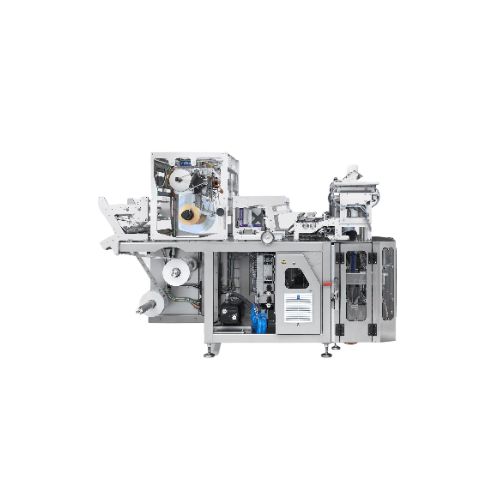

Intermittent vertical form fill seal for confectionery packaging

Optimize your packaging operations with this versatile ...

Continuous vertical form fill seal packaging solution

Experience unrivaled accessibility and efficiency in packaging fres...

Multi-station modified atmosphere packaging system for bulk products

Optimize your packaging efficiency with a system d...

Vertical form fill seal packaging for high washdown environments

Ensure optimal packaging in demanding environments with...

Chain conveyor for grain and floury products

Ensure seamless material handling with a versatile chain conveyor designed fo...

Advanced superheated steam drying solution

Harness the power of consistent drying technology to achieve optimal moisture c...

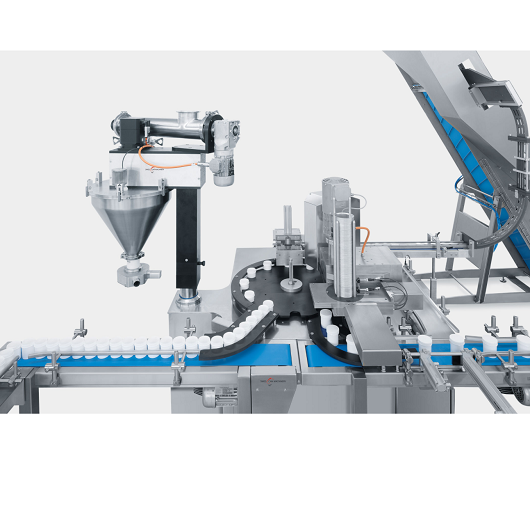

Fully automatic batch scale for powdery and granular products

Achieve precise and repeatable dosing for powdery and gran...

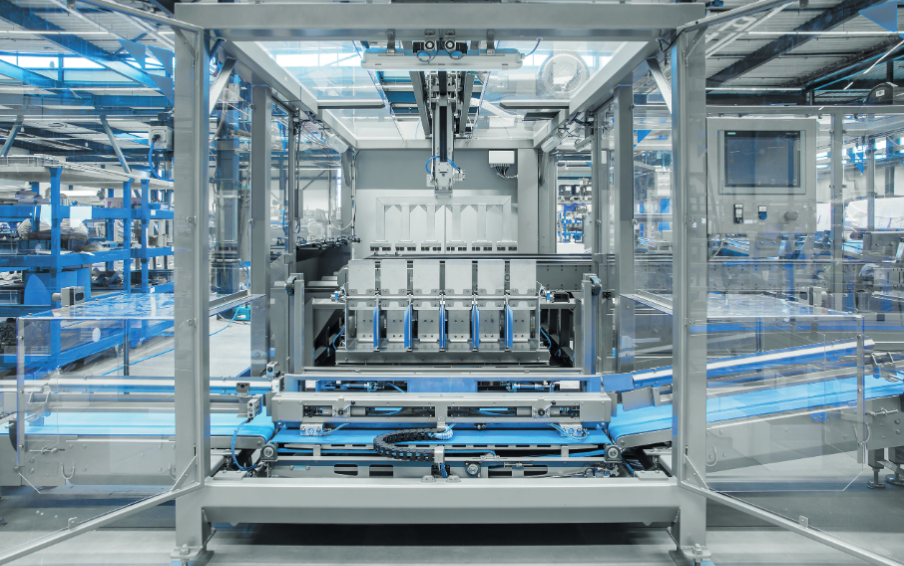

Top load and side load case packer with vision guided robotics

Optimize packing efficiency and flexibility with a versat...

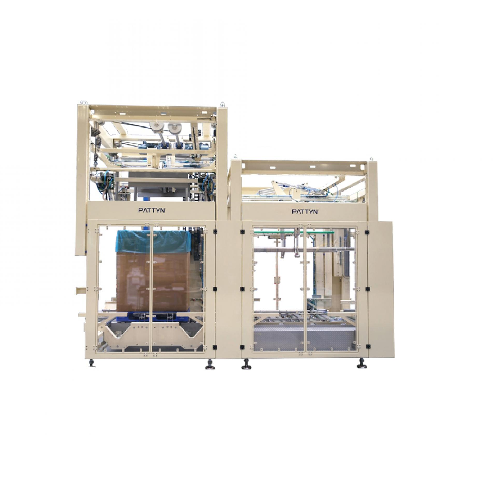

Vertical case packer for reusable and Rsc cases

Streamline your packaging line with versatile, high-speed case packing tha...

Gravimetric filling solution for inconsistent density products

Achieve precise weight accuracy in your filling processes...

Semi-automatic tray sealing for ready meals

Achieve versatile packaging with a semi-automatic tray sealing solution design...

Automatic tray sealer for high-speed food packaging

Optimize your production line with a high-capacity tray sealing solut...

High-speed tray sealer for food packaging

Streamline your packaging process with high-speed tray sealing, reducing labor c...

Automatic tray sealing system for high-speed packaging

Experience seamless high-speed packaging with this versatile tray ...

Automatic tray sealer for high-speed production

Ensure your product packaging stays fresh and secure with this high-capaci...

Industrial case packing solution for high-speed operations

Optimize your production line with a compact, efficient case ...

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

Hand operated tray sealer for small-scale food production

Optimize your packaging process with this compact tray sealing...

Bench mounted tray sealer with gas flush

Optimize your production line with a compact tray-sealing machine designed for pre...

In-line tray sealer for high-speed packaging

Optimize your packaging line with a high-speed solution that accommodates mul...

High-capacity tray sealer for vacuum gas packaging

Enhance your production efficiency with a versatile twin-lane tray sea...

In-line tray sealing system

Streamline your packaging line by implementing a high-speed, in-line tray sealing system designe...

High-capacity tray sealer for poultry, meat & seafood

Optimize your high-speed packaging line with this large-capacity tr...

Automatic tray sealer for high-speed packaging

Streamline your packaging line with an in-line tray sealer that adapts to t...

Large-capacity automatic tray sealer

Optimize your production line with this tray sealer, designed for high-speed sealing a...

Industrial high speed tray sealer

Enhance your production line efficiency with precision sealing capabilities, accommodatin...

Automatic tray sealer

Maximize throughput and shelf life with our high-speed inline tray sealing solution, ideal for diverse ...

Automatic tray sealing system

Optimize your packaging line with versatile tray sealing technology that accommodates various ...

Automated clipped netting system for meat packaging

Enhance your packaging line with a system designed for rapid and prec...

Powdered product shelf-life enhancement through inert gas packing

Extend the shelf life of sensitive powder products by...

Rotary pouch packaging system for food and powder products

Streamline your packaging process with a rotary system that e...

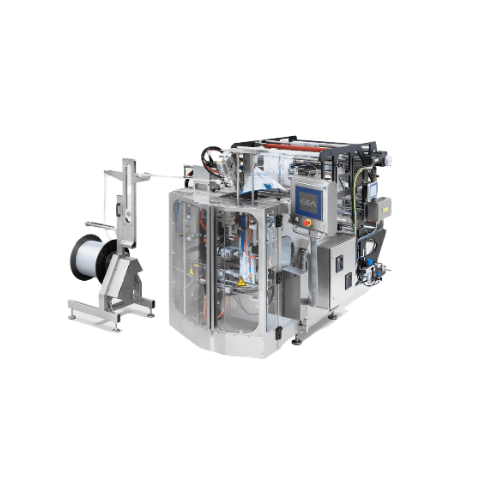

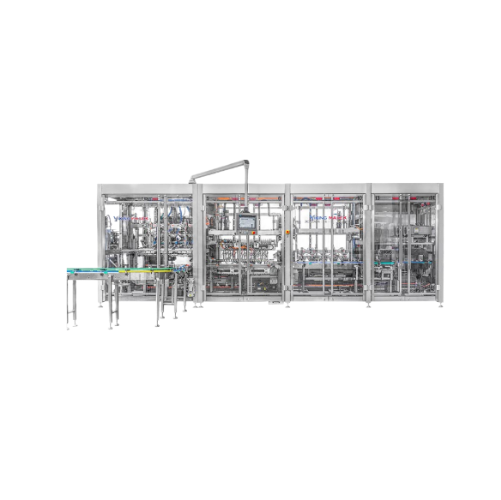

Continuous motion vertical form fill seal packaging system

Achieve high-speed, consistent packaging for diverse products...

High-speed vertical form fill seal packaging machine

Optimize your packaging line with this high-speed vertical form fill...

Vertical form fill seal for dusty and liquid products

Optimize your packaging line with a versatile solution designed to ...

High-speed vertical form fill seal for various packaging needs

Streamline your packaging process with an advanced vertic...

Vertical form fill seal for large bag packaging

For operations requiring precise, large bag packaging, this equipment ensu...

Vertical form fill seal for bulk bag packaging

Streamline your bulk bag packaging with efficiency and precision, ideal for...

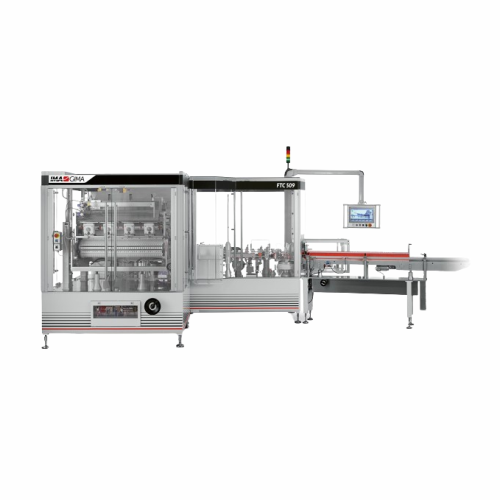

Topload cartoning system for efficient product packaging

Streamline your packaging line with this compact system that com...

Topload cartoner for packaging cartons

Efficient flap closing for diverse carton sizes, ensuring gentle handling of sensiti...

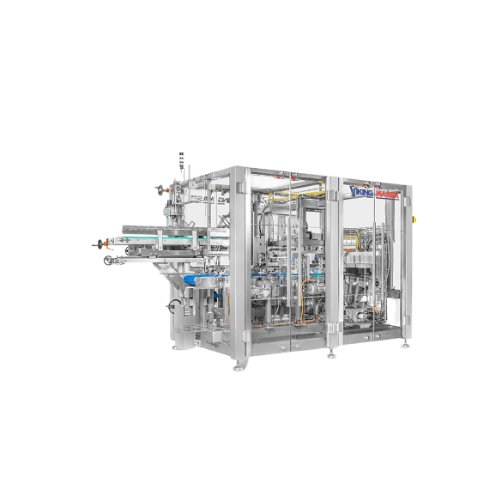

Rotary premade pouch filler and sealer

Maximize production efficiency by seamlessly filling and sealing diverse pouch sizes...

Automatic rotary premade pouch filler and sealer

Optimize your production line with high-speed pouch filling and sealing, ...

Automated infeed and outfeed systems for packaging lines

Streamline your production line by integrating reliable infeed a...

Modified atmosphere packaging solutions for perishables

Extend the freshness and shelf life of perishable goods with prec...

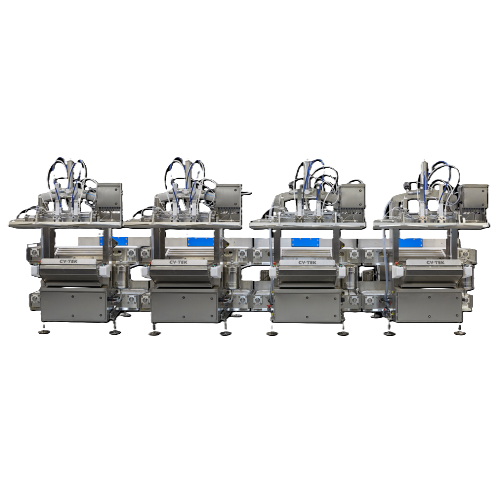

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Robotic packaging integration for automated systems

Enhance your production line efficiency with seamless robotics integr...

Sleeve cartoners for ready meals and salads

Optimize your packaging line with a high-speed sleeve cartoner designed to eff...

Vertical packaging system for medium-high speed applications

Optimize your packaging line with a system that delivers pr...

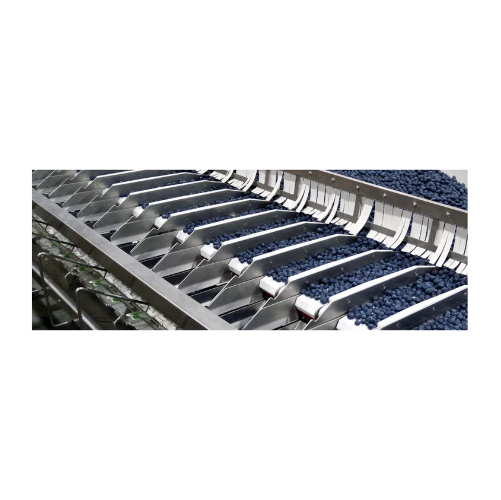

Dry bin filling for delicate fruit

Achieve gentle, high-throughput filling of delicate fruits with minimized manual interve...

High-speed filling system for cherries and blueberries

Streamline your packaging process with a system designed for rapid...

Cherry sorting system with deep learning technology

Boost your fruit processing efficiency by utilizing advanced deep lea...

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

Modular packing system for multihead weighing

Streamline your production with a versatile multihead system designed for pr...

multihead weigher for dry products

Optimize your production line with precise weighing for dry products, ensuring high-spee...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

Rotary pouch filling system

Looking to efficiently manage pouch filling for diverse products? This rotary system seamlessly ...

Garlic splitting and peeling line

Streamline garlic processing with this high-speed line designed to efficiently split, pee...

Robotic pick and place platform for food packaging

Enhance your packaging efficiency and product quality with a scalable ...

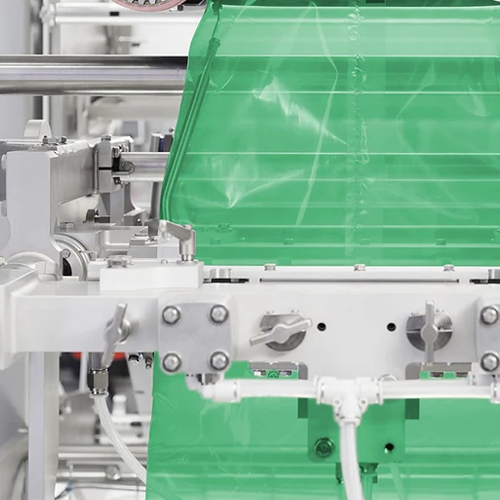

Vffs packaging solution for diverse bag styles and high hygiene standards

Enhance your packaging operations with high-...

Industrial bag sealing solution for medical and food applications

Enhance your packaging line with reliable and versati...

Side Load Case Packer For Packaged Food

Accuracy is a primary concern for case-packing pre-packaged foods such as milk or p...

Vacuum and Gas Injection System for FIBCs

Products packed in large bulk bags, such as FIBCs, require vacuum pressure and a...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Robotic case packing machine for snack bags

Automated packing with robotic suction arms can quickly pickup packaged produc...

Confectionery bags case packer for large scale

Mass production lines need faster and more efficient package processing to ...

Capping machine for plastic lid oatmeal tins

Some products ask for a plastic reusable lid after the can has been sea...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...