Machinery And Equipment For Processing Pistachio Nuts

Find innovative production technology for making pistachios and connect directly with world-leading specialists

Pistachio nuts offer several health benefits and are very nutritious. The most common way they are enjoyed is when they are roasted or eaten raw. Generally, pistachios are harvested when the shell splits. They are mechanically shaken and caught in a tarp. Furthermore, you can hull and dry them properly before roasting. To achieve all of this, you will need special pistachio processing equipment

Select your pistachios process

Tell us about your production challenge

Roasting with pistachio processing machine

Pistachios are more delicious when roasted. When you roast the nuts, they produce more fragrance and full flavours. You can make both sweetened and salted pistachio nuts using pistachio machines like the batch roaster and the single belt roaster.

If you are roasting them unsalted, drizzle the nut with oil before putting it into the machine. When you are making the salted type, you need to make a salty brine (mix salt with water). Then, put it into a clean spray and spray on the pistachios just before roasting. For the sweeter version, you can use sugar, cayenne or cinnamon just before roasting. Then you sprinkle the sweetener on the pistachio and roast it.

Does aflatoxin affect pistachios?

Pistachio nuts can get moulds on the surface due to aflatoxin. Aflatoxins are a family of toxins usually found in agricultural products like nuts and maize. These toxins are abundant in humid and warm environments. When pistachios are still good, they are yellow or green. When they get contaminated by aflatoxin, they begin to change to a darker brown colour because of harmful moulds.

Also, you have to take certain precautions as a producer to make safe pistachios. You have to ensure that there is no mechanical damage done during harvesting because they are fragile. If broken during harvest, they can get contaminated. With the right equipment and machine, producers are able to minimize this damage.

Pistachio producers and processors should also ensure that the nuts are not stored for too long. This will make them not turn rancid. The nuts should be stored in a dry place to prevent mould growth.

How to store pistachios properly

You store pistachios in an airtight container and pop them into a refrigerator. This way, you can maintain freshness and quality. There, they can be stored for up to 3 months. If stored at room temperature, they can last up to 2 weeks. When stored in a pantry, they can last up to 3 weeks.

Note that pistachios can be highly flammable if you pack them tightly or store them in large quantities. You should also not store them for too long. The oils in them can self-heat and cause spontaneous combustion. They self heat because of their high fat and low water content.

Processing steps involved in pistachios making

Which pistachios technology do you need?

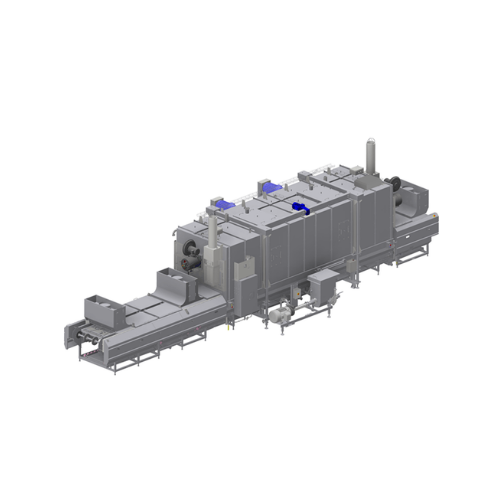

Nut roasting process with halved energy consumption

Achieve significant energy savings while maintaining high-quality roa...

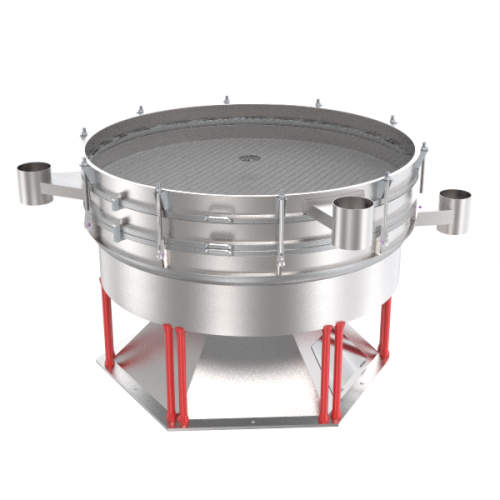

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

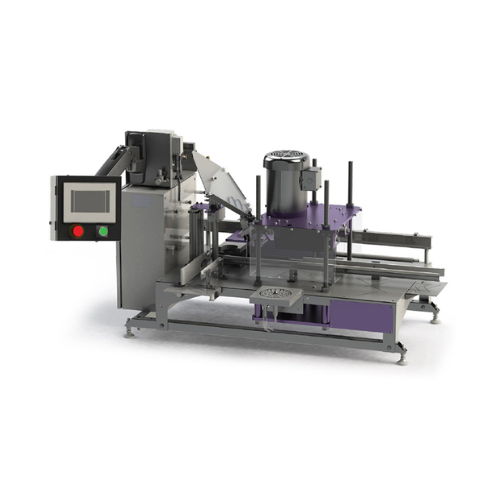

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

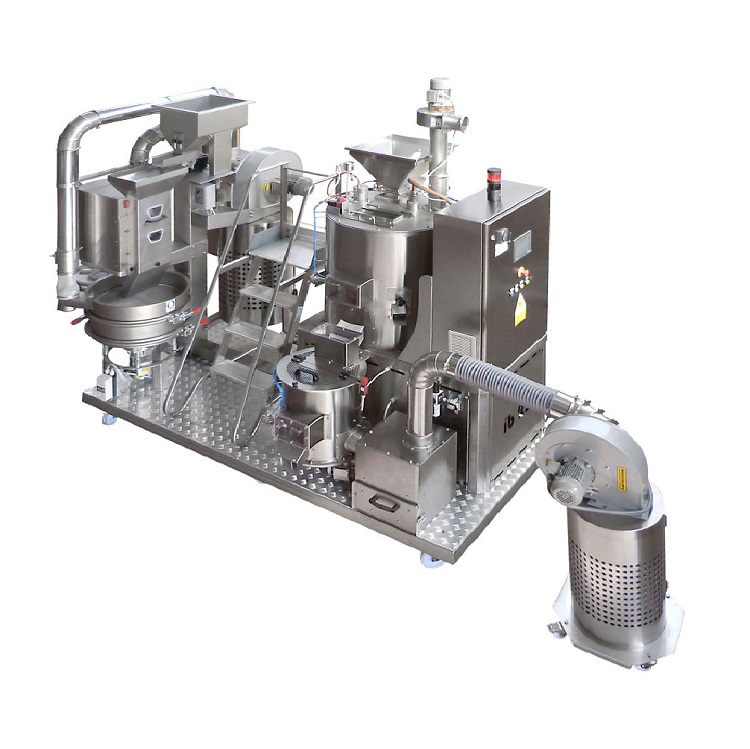

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

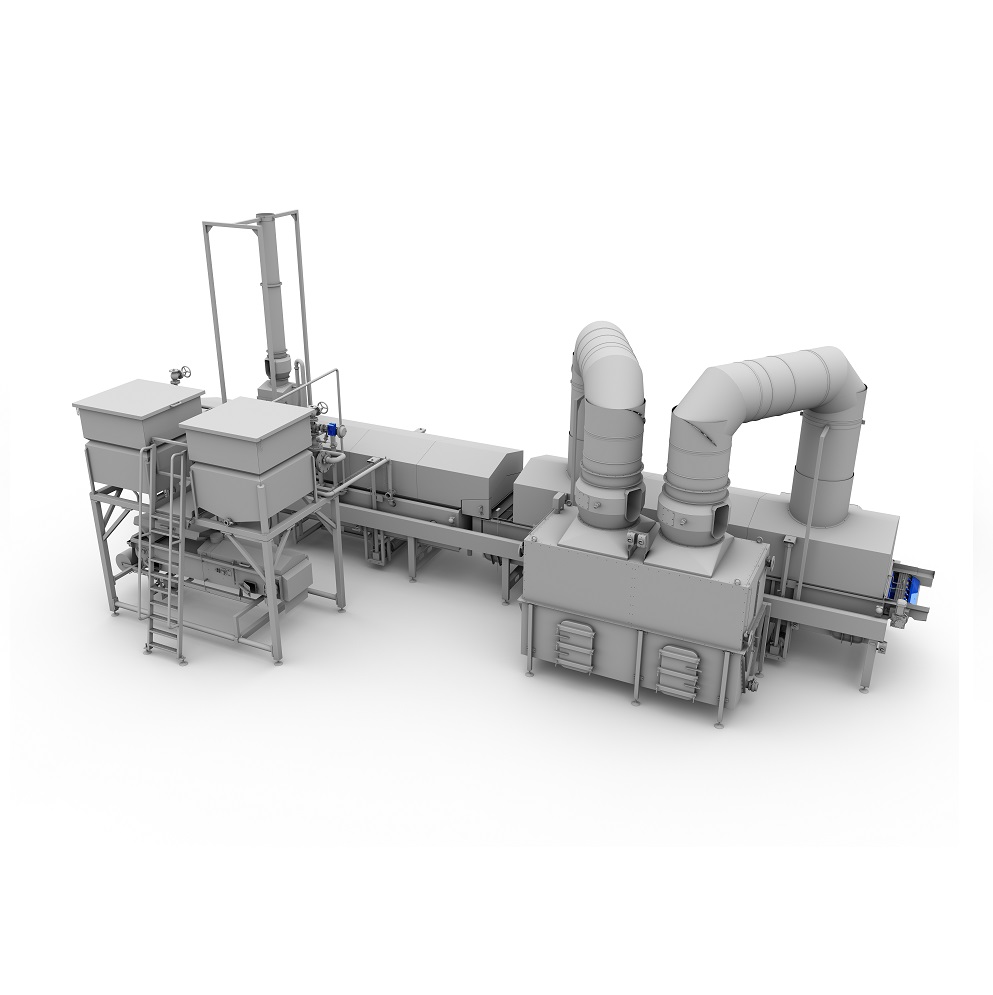

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Industrial pistachio peeler

Efficiently remove the interior hull from pistachios with mechanical friction, ensuring high-qua...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

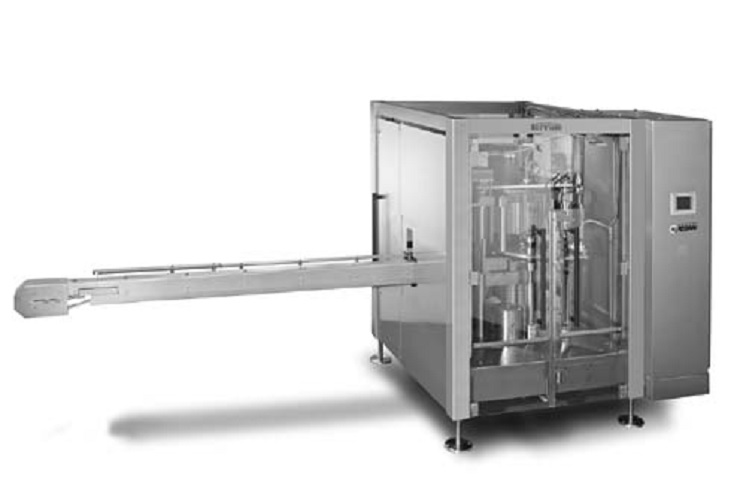

Modified atmosphere packaging for bulk bins

Achieve ultra-low oxygen levels and preserve product quality during bulk proce...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

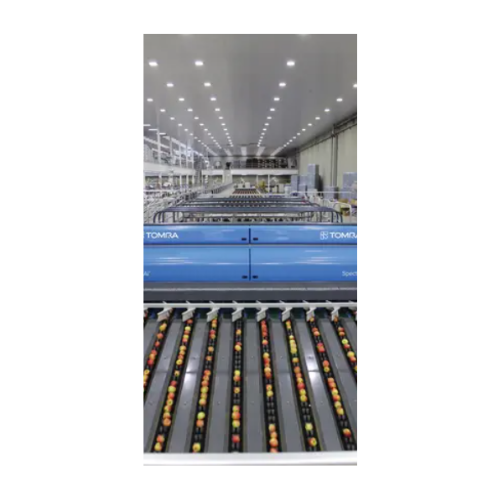

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Batch roaster for nut processing

Achieve precise roasting and flavor development with batch roasters that offer customizable...

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

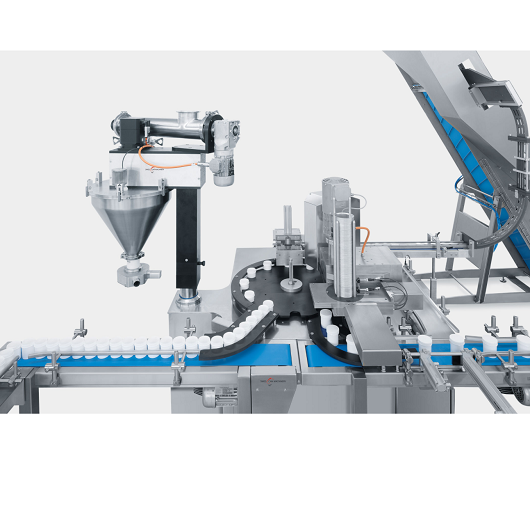

Premade pouch fill and seal solution

Effortlessly fill and seal various pouch sizes for streamlined packaging in diverse fo...

Food sorting system for nuts and dried fruit

Streamline sorting processes by removing visual irregularities, defects, and ...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

Nuts paste refining mill

Transform nuts and dried fruits into fine pastes with precise particle control, ideal for creating p...

Dried nuts roasting system

Efficiently transform raw dried nuts into high-quality pastes and creams, optimizing flavor and t...

Chocolate and sugar coating system

Achieve consistent, high-quality coating for nuts, dried fruits, and confectionery with ...

Industrial nut crusher for dried fruit processing

Optimize your nut and dried fruit processing by reducing them to precis...

Chocolate and nut cluster production line

Optimize your confectionery production with precise control over chocolate and n...

Cluster production system for chocolate with nut inclusions

Efficiently create customized chocolate clusters with precis...

Coffee, dried nuts, and cocoa beans roaster

Achieve precise and customizable roasting for a variety of beans and nuts with...

Industrial roaster for coffee, nuts, and cocoa beans

Optimize your roasting processes with a versatile solution designed ...

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

Semi-manual can sealer

When starting out in the canned product business, you do not necessary want to invest in industrial sc...

Seaming machine for infant formula cans

Packaging of food products, but especially those for babies, like infant formula, i...

Medium scale round can seamer

Automatic seaming of cans of craft bear can be quite the hassle with the movement from the cen...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Entry-level high volume package seal tester

Manufactured food products need to be packed in gas-filled pouches to ensure t...

R&D roaster for cocoa beans

When designing a new chocolate line or experimenting with new ingredients for existing processes...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Small scale nut grinder

Many confectionery and bakery processes rely on the uniform grinding of raw ingredients such as nuts,...

Can filling equipment

Having separate equipment for different process steps like filling and closing, can put a brake on grow...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

High performance can seamers for the food industry

The wide variation of materials and dimensions used in the food cannin...

Industrial nut grater

Pressure from the grinding process can cause damage to food products as well as induce unwanted heating...

Nut dicer

Dicing nuts can generate a large volume of wasteful and messy powdered nut residue.

Nut roaster

Nut roaster that guarantees a high-quality roasting of nuts and seeds with a batching capacity of 40 and 120 kg, d...