Cashew Processing Equipment

Find innovative production technology for making cashews and connect directly with world-leading specialists

Cashews come from a tropical tree native to Central America. They have become prominent and your nut mix will not be complete without them. The cashew processing method involves roasting, shell drying, peeling, grading, fumigation and packaging. You have to conduct these processing methods with care to obtain quality cashew nuts. In order to achieve this, you'll need the appropriate machinery for your cashew processing plant.

Technology picks for cashew processing

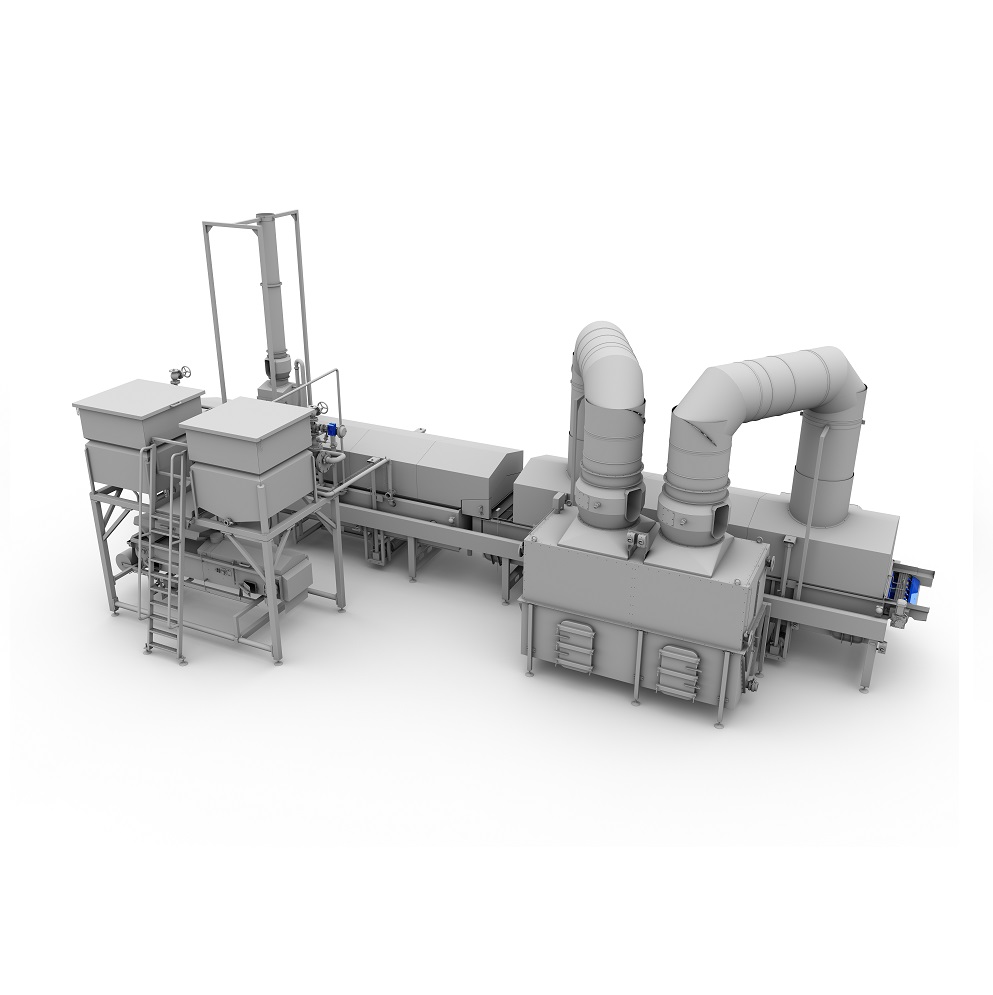

Small scale cashew nut processing plant

Optimize your nut processing with our comprehensive cashew line, designed to stream...

Dairy alternative production technology

Transform your production line with efficient dairy-alternative technology, enablin...

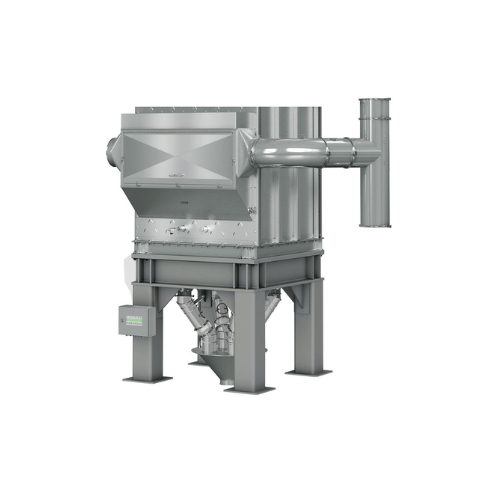

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Tell us about your production challenge

Cashew processing machines you need

To make and process raw cashew nuts, you’ll use different cashew processing machines. This equipment is found in almost all cashew nut processing plants. As an example, an automatic cashew nut grading machine classifies cashews in sizes, shape and dimensions, so you can separate kernels. A steaming machine, in its turn, softens the cashew nut shells so you can obtain the edible seed inside. You’ll also need a peeling machine, along with a cashew nut shelling machine and suitable cutting equipment. After all is done, you will also need a packing machine. Most machinery are fully automatic when it comes to all of these processes.

You can choose to either roast or fry cashew nuts. Roasting the cashew nut improves their taste and texture, while also enhances the overall savory sensory experience. Also, they are easier to digest and roasting decreases exposing them to harmful bacteria like Salmonella or E.Coli.

Note that roasting increases the calorie content of the raw cashews. The nuts will also have a higher sodium content when roasted. Fried cashews, on the other hand, are more versatile. You can fry them with white pepper, garlic and salt before packaging. Their only downside is that they have slightly higher calorie content compared to roasted nuts.

Watch out for the oil turnover time with cashew processing

When frying cashew nuts, take note of the oil turnover time. Oil turnover is the number of hours required to add makeup oil as you fry, to maintain the original amount of oil needed in the fryer. Furthermore, the oil turnover time should be shorter because the shorter it is, the fresher the oil will be. This translates to a longer cashew nut’s shelf life. Factors such as the type of oil you use and frying temperature affect the oil turnover time with cashew processing. Using darker oils with high viscosity, for instance, makes it harder to know how fresh the oil is, and the right time to turnover.

Regulations for the production of cashew

There are some necessary measures you have to take to prevent diseases in cashews and preserve them. When you have split the cashews, you can roast them or dry them with salt to prevent E.Coli from growing on the nuts. You can also use a protective coating of copper-based fungicide on parts of the cashew plant to prevent anthracnose, a fungal disease that affects plants in humid areas.

When making nuts for the US market, ensure that you abide by the US Food and Drug Administration rule that requires all in-shell nuts to be stored separately from the processing operation. Guarantee that they are free from filth and E.Coli, and pasteurize them to avoid pathogens such as Listeria and Salmonella. The same process would apply for most industries where cashews are produced. Contact us if you are looking to find the perfect cashew nut processing machine.

Many people are not aware that cashew nuts come from the cashew fruit. The nut itself looks almost like a stem. When you see the cashew growing, you’ll notice it looks completely different to the final product. That is because the nuts and cashew kernels need to go through a cashew shelling machine as well as various other processes to get to end product that we see in supermarkets.

Furthermore, cashew shells contain poison similar to that found in poison ivy. For that reason, unprocessed cashews are incredibly dangerous and it is critical that they go through the correct processing to make them safe for consumption. All of this used to be done by hand. However, In order to minimize contact with humans and the harmful poison, cashews have to go through an automatic cashew shelling and cutting machine. Grading cashews is also an important part of this process. And finally, roasting machines ensure that all of this harmful material is completely removed. Once again making it totally safe for us to eat.

cashews require intense processing in order to get to the final product and therefore are one of the more expensive nuts. Thus making the cashew industry big business.

Cashew processing machinery typically includes machines like a shelling machine, nut peeling machine, and nut cutting machine. For businesses looking for a complete solution, turnkey cashew processing plants are available that include all the necessary machines and equipment required for a production line. The cashew nut cutter is an essential machine used in the cashew processing line for cutting the cashew nut into smaller pieces for further processing or for packaging.

Processing steps involved in cashews making

Which cashews technology do you need?

Vertical nut dryer

Achieve precise moisture control for nuts with a vertical dryer that optimizes space and adapts seamlessly...

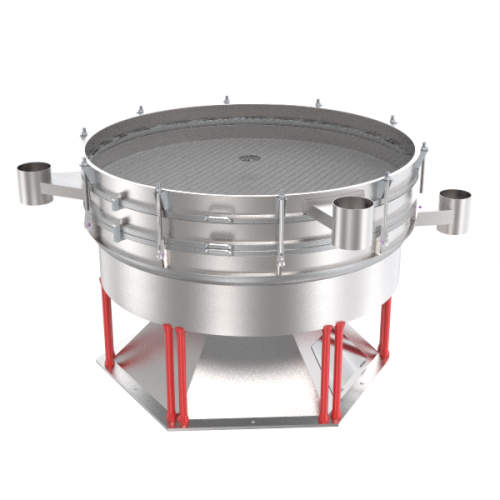

Circular sifter for fatty products and flours

Achieve precise separation and grading of nuts and flours, optimizing your p...

Destoner for nuts and seeds

Efficiently separate heavier particles like stones from a wide range of food products, including...

Nut dicing machine

Efficiently transform whole nuts into uniform cubes with precision cutting technology, ideal for creators ...

Nuts flour production system

Enhance your nut processing efficiency by transforming whole nuts into fine, consistent flour w...

Cooling system for heat-treated products

Efficiently reduce temperatures of high-heat products to protect quality and textu...

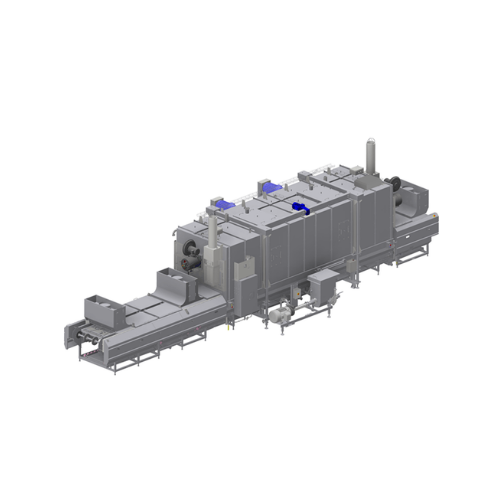

Horizontal roaster system for nuts and seeds

For nut processors aiming to achieve uniform roasting, this system ensures pr...

Nuts dust and impurity removal system

Enhance your nut processing line by effectively eliminating dust and impurities, ensu...

Aspiration system for nut processing

Streamline your nut processing with precise removal of skins, dust, and lightweight pa...

X-ray food inspection system for loose products

Ensure contaminant-free loose products by integrating a versatile inspecti...

Vertical bagging system for heat sealing films and Lpde

Achieve unparalleled flexibility with a versatile vertical baggin...

Rotary can filler for dry free-flowing products

Achieve precise, high-speed filling of dry free-flowing products like nuts...

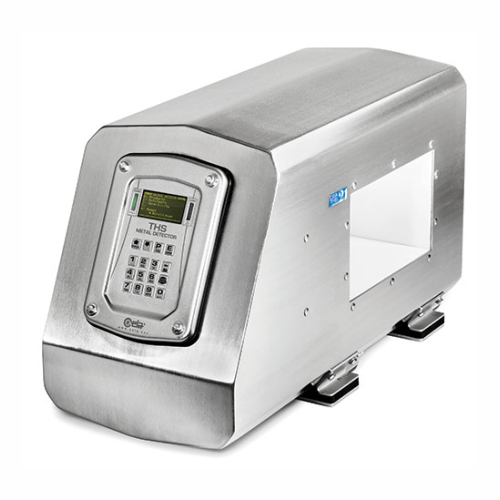

Multi-spectrum metal detector for food industry

Achieve unmatched detection accuracy in your food processing line with thi...

High volume rotary dryer roaster for continuous drying

Achieve uniform drying and roasting with a continuous, high-capaci...

Nut roaster for consistent and high-capacity processing

Achieve uniform roasting and elevate your nut processing with pre...

Nut roasting system

Achieve perfectly roasted and seasoned nuts with precision control over roasting, coating, cooling, and g...

Industrial heat recovery system

Transform exhaust heat from fryers into usable energy, reducing operational costs and boosti...

Oil curtain fryer for snack production

Enhance snack quality and shelf life by frying with rapid oil turnover and minimal o...

Nut and seed roaster for snack production

Ensure precise roasting and cooling of nuts and seeds while maintaining hygiene ...

Universal mill for grinding nuts and seeds

Optimize your nut paste production with a high-speed, versatile milling solutio...

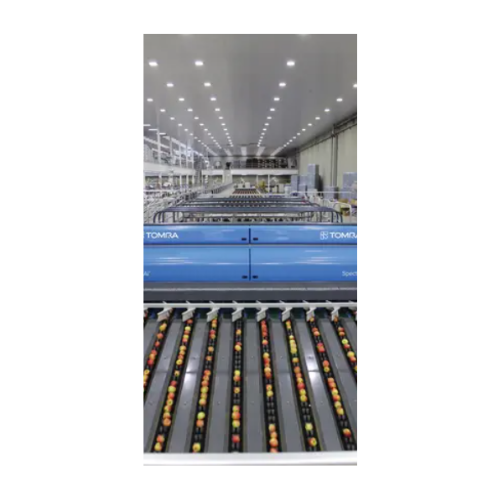

Optical sorter for grains, coffee, nuts, and plastics

Ensure consistent product quality and minimize waste with advanced ...

Optical sorter for nuts or dried fruits

Ensure maximum food safety and quality by efficiently sorting and removing shells, ...

Optical sorter for coffee beans

Achieve precise color differentiation and advanced foreign matter detection, optimizing your...

Hydrothermal kiln for oats and sorghum

Optimize your grain production with advanced enzyme inactivation and hydrothermal tr...

Bagging control system for centralized operations

Streamline your bagging operations with a centralized control system, d...

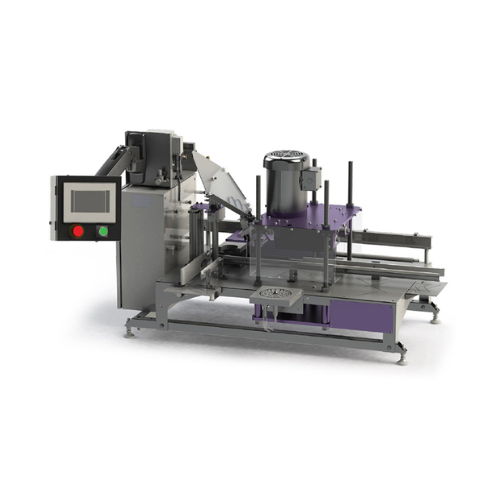

Bench mounted tray sealer for small-scale production

Perfect for pilot runs and small batches, this compact tray sealer e...

High throughput tray conveyor system

Looking to streamline your tray sealing process? This modular conveyor system integrat...

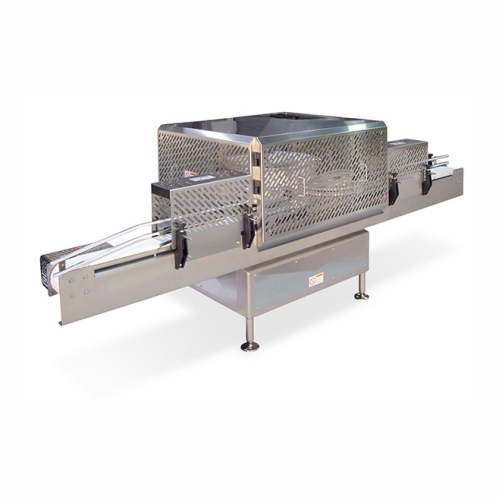

Surface pasteurizer for low moisture foods

Ensure a pathogen-free surface on low moisture products without altering their ...

Industrial spiral freezer for high-volume food processing

Optimize your production line with a modular spiral freezer th...

Vertical form-fill-seal for pillow bag packaging

Looking to enhance the speed and reliability of your packaging process? T...

High-speed vertical packaging system for candy and snacks

Achieve up to 500 pillow bags per minute with our high-speed p...

X-ray scanner for bulk material inspection

Ensure product safety and minimize downtime by intercepting foreign contaminant...

Product inspection systems for contamination control

Ensure product safety and compliance with precision inspection techn...

Robotic palletizing and depalletizing systems

Enhance your production efficiency by automating the repetitive and labor-in...

Industrial product fillers for precise packaging

Achieve consistent package weights and volumes with precision filling sol...

Large-capacity commercial food dehydrator

Achieve precise dehydration for a wide range of food items with unmatched consis...

High-precision sorter for nuts, coffee, seeds, and grains

Achieve unrivaled accuracy in sorting nuts, seeds, and grains ...

Intelligent optical fruit sorting and grading system

Enhance product quality and reduce waste with cutting-edge optical s...

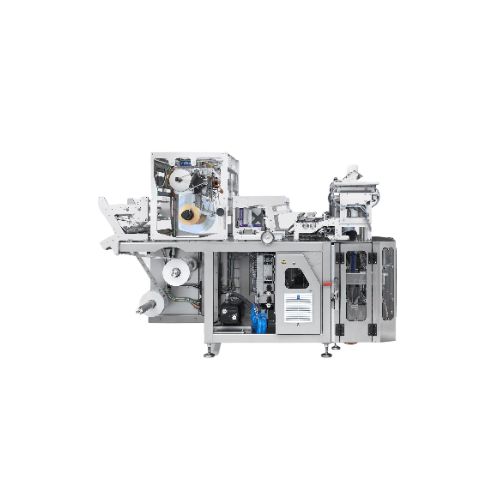

Modular linear packing system for granular products

Streamline your packing operations with a versatile system that integ...

10 head multihead weigher for dry products

Optimize your weighing and packaging operations with precise and rapid handling...

Industrial almond slicer for nut processing

Achieve precise nut slices with adjustable thickness, perfect for enhancing pa...

Peanut roaster for various nuts

Elevate your nut processing with efficient roasting solutions that enhance flavor, texture, ...

Nut coating machine for snack food processing

Enhance your snack and confectionery production with a nut coating machine t...

Stainless steel peanut butter grinder

Optimize your production line with high-speed emulsification and grinding, achieving ...

Garlic peeling equipment for industrial applications

Achieve optimal peeling efficiency with this garlic and nut peeling ...

Fully automatic electric heating frying system

Streamline your frying operations with a versatile system that not only sav...

Small scale cashew nut processing plant

Optimize your nut processing with our comprehensive cashew line, designed to stream...

Electrostatic drum flavoring system for food processing

Enhance your snack production efficiency with a system designed t...

Vacuum and Gas Injection System for FIBCs

Products packed in large bulk bags, such as FIBCs, require vacuum pressure and a...

Automatic FIBC Sealing machine

When sealing large bags containing bulk products, a sealer must be reliable to keep the MAP s...

Sensor for Modified Atmosphere FIBCs

Every year, more than 200 million FIBCs are filled with food for storage and transport...

Modified Atmosphere Big Bags

Manufacturers requiring big bag packaging have specific sizes, shapes, and material requirement...

Continuous bagger with twin sealing jaws

If you want to pack into gusseted and pillow style bags and packing speed is impor...

Frying line for nuts

Frying is one of the most common preparation methods for nut snacks. Oils bring out distinctive flavors,...

Industrial Nut Roaster

Moisture considerably depletes the shelf life of nut products. At the same time, however, manufacturer...

Bagger with mechanical driven jaw actuation

If you want to pack into unique bag styles like Quad-seal and Doypack, but you...

Case packer machine for pouches

Automated case packer machines are a good solution to achieve reliability and to increase th...

Nut and cheese grater

Smearing, clumping and crumbling are common problems when cheese and other soft textured foodstuffs are...

Washing cabinet for food bulk containers

With an ever-increasing demand for output and stricter hygiene regulations for foo...

Pillow bag vertical packing machine

When packaging products such as seeds, cereal, snacks, candies, nuts, tea, dried fruits...

Hygienic chocolate coating machine

Coat your product with chocolate or caramel. This is a next-generation chocolate coating...

High Speed Premade Pouch Packaging Machine

Pre-made pouches can be problematic for traditional cam-driven mechanical HFS m...

Entry-level infrared nut drying machine

For small scale production of cocoa beans and nuts, the use of traditional toasters...

Small scale nut chopping machine

Many confectionery and bakery products use nuts as a key ingredient or decoration. The abil...

Compact cylindrical roaster for beans, nibs and nuts

Roasting times and temperature can vary depending on the type of pro...

Packaging machine for sealed plastic bags from 250 g to 10 kg

Sealing small quantities of solids or liquids into plastic...

Continuous vertical bagger

Want a machine to pack unique bag styles such as quad-seal and Doy-pack bags at incredible speeds...