Iqf freezer for fruits and vegetables

Achieve perfect individual quick freezing with fluidization technology, ensuring delicate products like strawberries and plant-based protein chunks maintain their quality and appearance, while maximizing hygiene and efficiency in your food processing line.

Freezes and Fluidizes Delicate Food Products

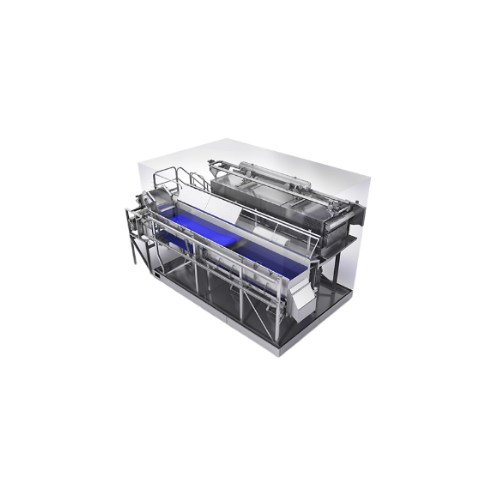

The Frigoscandia FLoFREEZE IQF Freezer by JBT Corporation delivers efficient and high-quality freezing solutions for the food industry. Specializing in fluidized bed freezing, it features a patented airflow system that enables true fluidization, offering stable, dual-zone operation. This innovation ensures even freezing of delicate food items, from peas and corn kernels to strawberries and plant-based protein chunks, maintaining their shape and texture.

Designed specifically for continuous, high-speed operations, the freezer can handle capacities from 1 to 17,500 metric tons per hour, based on frozen peas. Its pulsation system modulates air pressure and frequency to gently separate product layers during crust freezing, enhancing throughput while maintaining product integrity. The Agitation system further ensures proper Individual Quick Freezing (IQF) at the initial stages.

For integration into production lines, the freezer is PLC-controlled, offering real-time monitoring to adapt to various operation conditions. Options such as the ADF Air Defrost System and LVS FRIGoPAK® for low volume refrigeration enhance operational efficiency and minimize energy consumption. Constructed with stainless steel trays for hygiene-critical environments, it meets the stringent standards of food safety and quality, providing reliable performance for fruits, vegetables, and plant-based protein processors.

Benefits

- Increases product yield and quality by maintaining the integrity of delicate food items during freezing.

- Enhances production efficiency with high throughput capabilities up to 17,500 metric tons per hour.

- Reduces energy consumption through optimized airflow systems and refrigeration options.

- Provides flexibility with customizable options to meet specific production needs and hygiene standards.

- Ensures seamless integration and operation with PLC-controlled systems for real-time process management.

- Applications

- Potatoes, Fruits, Nuts, Plant-based protein, Vegetables

- End products

- Frozen strawberries, Frozen potato wedges, Frozen plant-based protein chunks, Frozen mixed vegetables, Frozen diced carrots, Frozen peas, Frozen blueberries, Frozen corn kernels

- Steps before

- Washing, Blanching, Cutting, Sorting

- Steps after

- Packaging, Labeling, Storage, Distribution

- Input ingredients

- fruits, vegetables, peas, corn kernels

- Output ingredients

- frozen fruits, frozen vegetables, frozen peas, frozen corn kernels

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Freezing Capacity

- 1 to 17, 500 metric tons per hour

- Fluidization System

- Dual zone with separate pressure chambers

- Pulsation System

- Air pressure and frequency modulation

- Air Bypass

- Fine-tuned airflow

- Material

- Stainless steel IQF tray

- Pulsation System

- Crust freezing stage agitation

- Options

- ADF Air Defrost System, SD Sequential Defrost System, LVS FRIGoPAK® system

- Fluidization type

- Fluidized bed

- Freezing zones

- Multi-zone

- Automation level

- PLC-controlled

- Air bypass

- Adjustable

- Agriculture product compatibility

- Fruits and vegetables

- Capacity range

- 1-17, 500 metric tons/hour

- Defrost system

- ADF Air Defrost / SD Sequential Defrost

- Agitation type

- Back and forth

- Cleanability

- High

- Corrosive resistance (e.g. acids)

- Stainless Steel

- Biological compatibility

- Yes

- Abrasion resistance

- Moderate

- Product Sensitivity

- Delicate Products

- Hygiene Standards

- Industry Food Hygiene Standards

- Patented Technology

- Patented air flow system

- IQF Track System

- Dual zone fluidization

- IQF Tray Material

- Stainless steel

- Options

- ADF Air Defrost System, SD Sequential Defrost System, LVS FRIGoPAK®

- Footprint

- Compact design

- Refrigeration system

- LVS FRIGoPAK® low volume refrigeration system