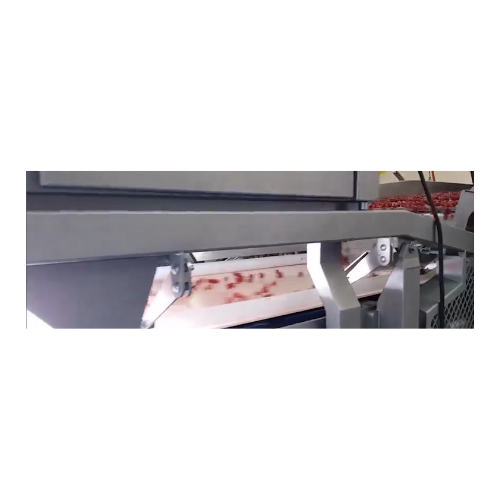

Belt sorter for potatoes and leafy vegetables

Enhance the precision and efficiency of your sorting process with a system designed to seamlessly handle a variety of solid and granular food products, ensuring consistent quality and reducing waste through advanced detection and ejection features.

Sorts and Inspects Food Products with Precision

The TOMRA 5B, from acclaimed manufacturer TOMRA, excels in enhancing product quality through precise sorting and inspection. Utilizing advanced sensor technology and innovative algorithms, this optical belt sorter detects color and shape defects with remarkable accuracy, essential for food processors dealing with a range of products, from French fries and potato chips to nuts and seafood. Operating at high speeds, it seamlessly ejects foreign materials and non-conforming items, ensuring only quality products proceed down the line. Its intuitive TOMRA ACT user interface simplifies operation while promoting ease of maintenance through a built-in health check. The TOMRA 5B is built for continuous operation, capable of handling substantial throughputs, making it an integral component for those focused on maximizing yield and meeting stringent quality standards. Configurable sorting parameters and a durable, easy-to-clean design ensure adaptability across diverse processing conditions, ultimately contributing to reduced waste and optimized production efficiency.

Benefits

- Maximizes yield by minimizing false rejects with advanced ejection technology.

- Enhances product quality through precise defect and foreign material detection.

- Increases operational efficiency with user-friendly interface and continuous high-speed processing.

- Reduces waste and optimizes resource use by customizing sorting parameters for varied applications.

- Simplifies maintenance with intuitive health checks and easily cleanable design.

- Applications

- Seafood, Proteins, Grains, Leafy products, Potatoes, Pet food, Meat, Nuts, Vegetables

- End products

- Grain mix pouches, Dehydrated potato flakes, Mixed vegetable bags, Diced carrots, Kibble for dogs, Bell pepper strips, Potato chips, Peeled shrimp, Flavored nuts, Green bean cuts, Spinach packaging, Cat food pellets, Seafood medley packs, Diced chicken pieces, French fries, Almond slices

- Steps before

- Sorting, Pre-cleaning, Pre-processing

- Steps after

- Quality Inspection, Packing, Final Processing

- Input ingredients

- potatoes, vegetables, proteins, leafy products, French fries, chips, green beans, spinach, peas, carrots, bell peppers, leafy veggies, baby spinach leaves

- Output ingredients

- sorted potatoes, sorted vegetables, sorted proteins, sorted leafy products, flawless potatoes, high-quality almonds

- Market info

- TOMRA is known for its expertise in sensor-based solutions for resource productivity, particularly in recycling, food sorting, and mining industries, offering advanced technology to improve resource recovery and efficiency, enhancing sustainability and operational performance.

- Accuracy

- ±0.01 mm

- Automation

- Advanced algorithms

- Inspection Coverage

- 360° view

- Sorting Parameters

- Shape, size, length-to-width ratio

- Foreign Material Detection

- Advanced sensor tech

- User Interface

- TOMRA ACT

- Ejection,Sort-to-Spec

- Smart Features

- Inspection method

- On-belt sensor inspection

- Sorting capability

- Shape, size, and length-to-width ratio

- Foreign material detection

- Sensors and algorithms for hard-to-find objects

- Automation level

- User-friendly interface with intuitive controls

- Yield optimization

- Smart ejection, sort-to-spec features

- Inspection view

- 360° view

- Batch vs. continuous operation

- Continuous inline

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Compact footprint

- Yes

- Control panel type

- TOMRA ACT User Interface

- Compact design

- Optimized for space efficiency

- Discharge method

- Belt

- Machine footprint

- Varies by customization

- Control panel type

- TOMRA ACT user interface

- Integration possibilities

- Advanced algorithms and sensor technology

- Sorting parameters adjustment

- Shape, size, and length-to-width ratio

- User interface

- Intuitive design

- Health check feature

- Pre-sorting assessment