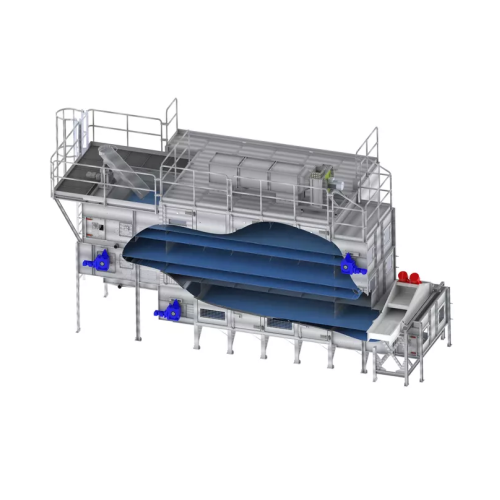

Layer dryer for food and pet food applications

Optimize drying efficiency with multi-layer technology that minimizes space, reduces energy costs, and enhances thermal performance—ideal for diverse material processing requirements.

Dries and Handles a Wide Range of Materials

The Belt Dryer Type BTF-L from STELA Laxhuber is a versatile layer dryer engineered for industries such as agriculture, timber, food, and beyond. What sets the BTF-L apart is its ability to maximize drying area while minimizing installation space through its multi-belt configuration. This design not only reduces heat loss but also optimizes energy consumption, as multiple belts can be ventilated with a single airflow system, lessening the demand for fans and heat sources.

Applications include drying cereals, OSB boards, dried fruits, and pet kibble, with customizable processing solutions for diverse end-products like granola, wood fibers, and sustainable fuel pellets. Capable of handling various material handling setups, this dryer integrates seamlessly into continuous production lines with options for PLC automation.

For energy efficiency, the BTF-L supports diverse heat sources such as gas, oil, and biomass, achieving significant reductions in electricity demand. Constructed with high-quality materials for durability and low maintenance, it allows for easy customization to meet specific drying needs across multiple industries.

Benefits

- Increases production efficiency with compact design reducing installation space.

- Lowers operational costs by minimizing heat loss and energy demand.

- Adapts to diverse drying needs for multiple industries and end-products.

- Offers flexible heat source options to use available fuels efficiently.

- Enhances product quality with controlled drying for various materials.

- Applications

- Water management, Berries, Cement industry, Pet food, Extrudates, Snacks, Recycling industry, Fruits, Renewables fuels, Foodstuffs, Pulp and paper, Pellet industry, Cereals, Bars, Nuts, Vegetables, Timber industry, Agriculture

- End products

- Wood fibers, Millboard, Osb boards, Protein bars, Berry chips, Sustainable fuel pellets, Dried apples, Dried vegetables, Paper pulp, Cornflakes, Celery flakes, High-quality pellets, Sludge granules, Cement clinker, Granola, Muesli base flakes, Potato crisps, Pet kibble, Raisins, Cat food crunchies

- Steps before

- Product placement, Swivel chutes, Swivel belts, Product chutes, Vibration chutes

- Steps after

- Vibrating chutes, Slides, Discharge conveyors, Screws

- Input ingredients

- nuts, cereals, extrudates, fruit, berries, vegetables

- Output ingredients

- dried nuts, dried cereals, dried extrudates, dried fruit, dried berries, dried vegetables

- Market info

- Stela Laxhuber is known for their expertise in manufacturing custom-engineered drying systems, particularly belt dryers for biomass, sludge, and food industries, with a reputation for innovation, quality, and energy efficiency in the market.

- Drying area

- Large in small installation space

- Layer configuration

- Multiple belts

- Heat generator options

- Gas, oil, biomass, electric boiler

- Heat carrier options

- Hot water, steam, thermal oil

- Energy efficiency

- High thermal energy efficiency

- Ventilation intensity

- Lower compared to stage dryer

- Exhaust air flow rate

- Reduced

- Compact design

- High belt areas, high dwell times

- Installation space requirement

- Reduced by number of belts

- Material handling

- Swivel chutes, vibration chutes, discharge conveyors

- Water evaporation capacity

- Medium or low

- Product suitability

- Nuts, cereals, extrudates, fruits, vegetables

- Automation level

- Consultation for customisation

- Airflow control

- Ventilation for multiple belts

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual / PLC / SCADA

- Energy efficiency

- High thermal energy efficiency

- Changeover time

- Quick installation within compact spaces

- Cleaning method

- CIP / Manual

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Low/Medium

- Moisture sensitivity

- High/Low

- Drying time requirement

- Medium to Long

- Agglomeration risk

- Low

- Water evaporation rate

- Medium/Low

- Material type

- Nuts, Cereals, Extrudates

- Specific water evaporation

- Medium/Low

- Ventilation intensity

- Lower compared to stage dryer

- Fruit and vegetable drying

- Applicable

- Pet food drying

- Applicable

- Layer drying

- Multi-layer belts

- Installation space

- Compact

- Thermal energy efficiency

- High

- Machine footprint

- Compact

- Layer configuration

- Multi-layer (up to 3 belts)

- Installation space

- Reduced

- Dryer housing type

- Layer dryer

- Discharge method

- Vibrating chutes, slides, discharge conveyors or screws

- Belts

- Multiple belts in one housing

- Belt area

- Large area in small space

- Heat source options

- Gas, oil, biomass, electric

- Heat carrier options

- Hot water, steam, thermal oil

- Ventilation system

- Common air flow for multiple belts

- Product feed

- Swivel chutes, swivel belts, vibration chutes

- Heat carrier

- Hot water, steam, thermal oil

- Heat generators

- Gas, oil, biomass, electric boiler

- Control panel type

- PLC-controlled

- Ventilation option

- Multiple belts with same air flow

- Installation configuration

- Compact with multiple belts

- Product handling technology

- Swivel chutes, vibration chutes