Spiral freezer for high-volume food products

Achieve rapid, sanitary freezing with this spiral system, designed to handle a wide variety of food products in high-volume operations, ensuring enhanced food safety and reduced downtime.

Freezes and Chills High-Volume Food Products

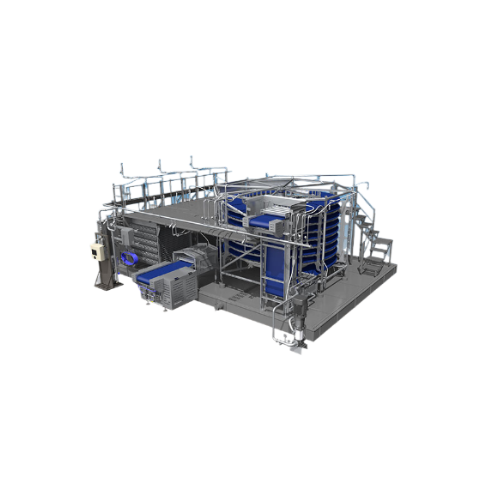

The Northfield CleanFREEZE™ Spiral Freezer by JBT is engineered for efficient, continuous freezing and chilling of high-volume food products. This spiral freezer excels in maintaining product integrity and hygiene, utilizing a fully welded enclosure and minimal joints to reduce bacteria traps. Its capless, solid plastic rails further enhance sanitation, making it ideal for applications in products like frozen yogurt, almond milk ice cream, and plant-based protein patties. Capable of handling diverse food items such as frozen shrimp, beef patties, and microwaveable ready meals, it operates with precision-controlled temperature environments to improve product quality and shelf life. With an optimized cold-to-cold turnaround time of just four hours, the CleanFREEZE meets the demanding throughput needs of modern food processors. Integrated with advanced design features, it reduces installation time by up to 30% compared to predecessors and supports efficient maintenance through externally-mounted fan motors. Customizable to specific user needs, the equipment offers modular systems that seamlessly integrate into existing production lines, enhancing operational flexibility and productivity.

Benefits

- Increases efficiency with a cold-to-cold turnaround of four hours, boosting production capacity.

- Enhances sanitation with design features that minimize bacteria exposure, ensuring food safety.

- Reduces labor and installation costs with advanced design that streamlines setup and maintenance.

- Offers flexibility with modular systems that adapt to changing production demands.

- Extends product shelf life with precise temperature controls and reliable food quality preservation.

- Applications

- Seafood, Ready meals, Meat, Dairy alternatives, Fruits, Nuts, Plant-based protein, Poultry, Dairy

- End products

- Pecan halves, Frozen shrimp, Soy-based burger patties, Beef patties, Mac and cheese ready meals, Frozen yogurt, Almond milk ice cream, Microwaveable lasagna, Frozen berries, Frozen chicken wings

- Steps before

- Portioning, Slicing, Marination, Forming, Packaging

- Steps after

- Packing, Labeling, Tray Sealing, Distribution, Storage

- Input ingredients

- raw poultry, par-fried poultry, fully-cooked chicken products, raw beef, raw pork, fully-cooked hamburger patties, sausage patties, sausage links, ground beef products, ground pork products, plain pizza crusts, topped pizza pies, breads, cakes, pies, donuts, bagels, ready meals in trays, handheld snacks, meat-filled treats, cheese-filled treats, fruit-filled treats

- Output ingredients

- frozen poultry, frozen beef, frozen pork, frozen pizza, frozen bakery items, frozen ready meals, frozen snacks

- Market info

- JBT is known for manufacturing industrial ETO equipment, specializing in food processing and airport ground support systems. They are reputed for innovative solutions and reliable service in industries requiring sophisticated automated systems and machinery.

- Turnaround Time

- 4 hours

- Freezer Type

- Spiral Freezer

- Food Product Compatibility

- Packaged and IQF products

- Temperature Control

- Precise

- Installation Time Reduction

- 30% over previous models

- Hygienic Design Features

- Fully welded enclosure, minimal overlapping joints

- Cooling Efficiency

- High-volume freezing and chilling

- Construction Material

- Solid plastic rails

- Working mechanism

- Spiral freezing technology

- Integrated steps

- Freezing, chilling, and cooling

- CIP/SIP capability

- Clean-in-Place optional upgrade

- Cold-to-cold turnaround time

- 4 hours

- Flexibility

- Accommodates a wide range of products

- Automation level

- Programmable control

- Changeover time

- 30% reduced installation time

- Batch vs. continuous operation

- Flexible to both, predominantly inline continuous

- Sanitary design

- Bacteria trap minimization

- Energy efficiency

- Optimized for reduced cost per unit

- Modular and customizable

- Yes

- Temperature control

- Precise environmental controls

- Freezing capacity

- High-volume

- Product type

- Packaged / Individual Quick Freeze (IQF)

- Material type

- Poultry / Beef / Pork / Bakery

- Application

- Freezing / Chilling / Cooling

- Hygiene level

- High food safety standards

- Turnaround time

- Cold-to-cold in 4 hours

- Sanitary design

- Fully welded enclosure

- Customization options

- Modular systems

- Maintenance ease

- Stairs instead of ladders

- Temperature control

- Precise

- Machine footprint

- Compact design

- Enclosure type

- Fully welded enclosure

- Frame design

- Open-profile frame

- Capless rail system

- Solid plastic rails

- Fan motor placement

- Externally-mounted

- Cooling method

- Spiral freezing

- Discharge method

- End-of-line discharge

- Programmability

- Customizable systems

- Modular construction

- Yes

- Slope design

- Sloped surfaces

- Control panel type

- Programmable

- Integration possibilities

- Modular and easy-to-integrate systems

- Customizable configuration

- Accommodates a wide variety of products

- Turnaround time customization

- Optimized for fast cold-to-cold turnaround

- Safety customization

- Smart design features for bacterial growth prevention

- Capless rail type

- Solid plastic rails

- Enclosure design

- Fully welded with minimal overlapping joints

- Environmental control

- Precise temperature controls