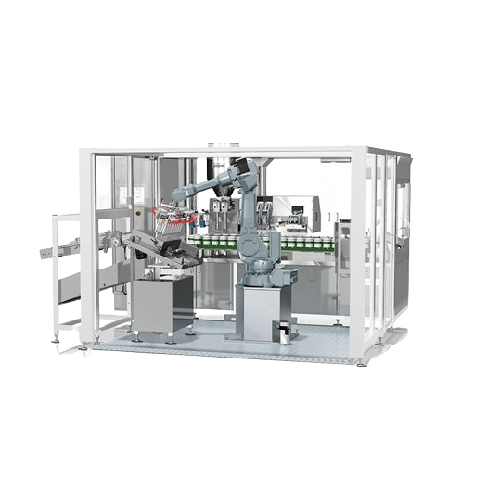

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head tube filler, designed for high-speed operations, ensuring accurate filling and sealing of various personal care and food products while enhancing production line sustainability.

Fills and Seals Tubes with Liquid Products

The NM 1703 from Norden is a robust twin head tube filling machine designed for precise and efficient packaging of liquid products such as sauces, condiments, and cosmetics. It operates using an intermittent filling process, meticulously handling tube diameters up to 65 mm at speeds of 170 tubes per minute.

This machine excels with its advanced Hot Air heating and sealing station, incorporating an integrated heat exchange function to enhance energy efficiency. It is equipped with the intuitive EasyWare control system for streamlined operations and real-time monitoring. The NM 1703 is apt for a diverse range of liquid applications including toothpaste, hand creams, and various personal care products.

With a maximum filling volume of 450 ml, it ensures high throughput without compromising accuracy. The machine’s construction offers compatibility with a variety of packaging materials like aluminum, laminated, and plastic, catering to cylindrical and oval shapes. Tailored for seamless integration into existing production lines, the NM 1703 is ideal for food and personal care product manufacturers aiming to optimize their packaging capabilities.

Benefits

- Enhances productivity with dual-head filling for high-speed operations.

- Lowers energy usage through an integrated heat exchange system.

- Ensures precise filling and sealing, minimizing material waste.

- Accommodates diverse packaging materials and shapes, increasing flexibility.

- Offers intuitive control and monitoring with EasyWare, reducing operational errors.

- Applications

- Food, Personal care, Sauces, Hair care, Sun care, Deodorants, Men's shaving, Skin care, Toothpaste, Cosmetics, Condiments, Liquid soaps

- End products

- Toothpaste gel, Sunscreen lotion, Face moisturizer, Liquid hand soap, Hand cream, Conditioner, Mayonnaise, Body lotion, Shampoo, Mustard, Antiperspirant roll-on, Aftershave lotion

- Steps before

- Mixing, Blending, Material preparation, Ingredients measurement

- Steps after

- Sealing, Cartoning, Labeling, Quality inspection, Distribution

- Input ingredients

- larger tubes, tubes up to 65 mm diameter, ingredients for food, cosmetic products, deodorants, men's shaving products, liquid soaps, toothpaste, skin care products, sun care products, hair care products

- Output ingredients

- filled tubes, packaged products, cylindrical packaging, oval packaging, sealed tubes

- Market info

- Norden Machinery, part of the Coesia Group, is renowned for its expertise in designing and manufacturing advanced tube filling machines, particularly for the pharmaceutical, cosmetics, and food industries, emphasizing precision and high-speed performance.

- Tube Diameter

- Up to 65 mm

- Filling Speed

- 170 tubes per minute (tpm)

- Max Filling Volume

- 450 ml

- Min Filling Volume

- 1 ml

- Packaging Material

- Aluminium - Laminated - Plastic

- Packaging Shape

- Cylindrical - Oval

- Machine Depth

- 3350 mm

- Machine Height

- 2455 mm

- Machine Length

- 4950 mm

- Machine Weight

- 4800 kg

- Max Pack Diameter

- 65 mm

- Min Pack Diameter

- 10 mm

- Max Pack Length

- 250 mm

- Min Pack Length

- 50 mm

- Operating Mode

- Intermittent

- Working mechanism

- Intermittent

- Automation level

- EasyWare control system

- Batch vs. continuous operation

- Batch

- Energy efficiency

- Improved HA

- Integrated steps

- Heating, Sealing with heat exchange

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Heat sensitivity

- Features integrated heat exchange function

- Viscosity

- Suitable for a range of products like liquid soaps and toothpaste

- Machine depth

- 3350 mm

- Machine height

- 2455 mm

- Machine length

- 4950 mm

- Machine weight

- 4800 kg

- Max filling volume

- 450 ml

- Min filling volume

- 1 ml

- Max pack diameter

- 65 mm

- Min pack diameter

- 10 mm

- Max pack length

- 250 mm

- Min pack length

- 50 mm

- Packaging Shape

- Cylindrical / Oval

- Control panel type

- EasyWare control system

- Integration possibilities

- Heat exchange integration