Two-component filling machines for food and beverage packaging

Streamline your filling process with precise two-component systems designed to maintain consistent product ratios while accommodating various packaging sizes and maintaining hygiene standards, ensuring your liquid formulations are blended and filled with high accuracy and efficiency.

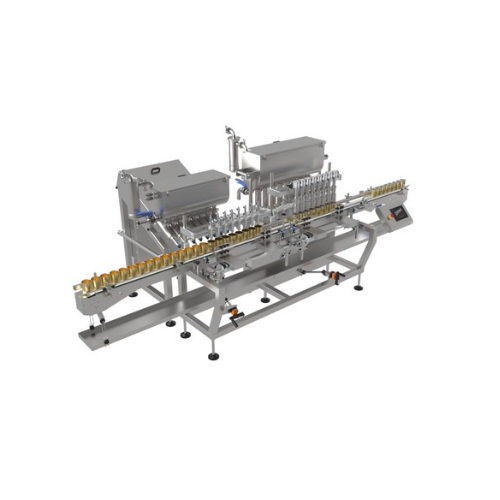

Fills Dual Liquid Components into Various Packages

The VD50-4 FOT and VD10-4 FOT from Kulp Makina are engineered two-component volumetric filling machines designed to enhance filling precision for food and beverage applications. These machines stand out with their dual filling systems that handle a variety of liquid products, such as vinegar-oil mixes and yogurt-jam combinations, ensuring high accuracy of ±1% and a capacity of up to 4,800 packages per hour. Featuring separate product hoppers with automatic level control, these machines integrate smoothly into continuous production lines. They operate pneumatically and electronically with a 6-bar compressed air system and consume 800 liters per minute at maximum throughput. Constructed using 316L stainless steel for product-contact parts, they assure durability and compliance with food hygiene standards. Optional features include a Cleaning-In-Place (CIP) system and custom sealings for high-temperature operations, ensuring ease of maintenance and adaptability.

Benefits

- Enhances production efficiency with precise dual-component filling, maintaining a ±1% accuracy rate.

- Increases operational speed to handle up to 4,800 packages per hour, optimizing output.

- Facilitates hygienic operations with easy-clean design and optional CIP system.

- Supports diverse product applications, minimizing the need for multiple machines.

- Ensures seamless integration into existing lines with modular and pneumatic design.

- Applications

- Sauces, Edible oils, Condiments, Balsamic products, Liquid food formulations, Vinegar blends, Dairy products, Juice blends

- End products

- Vinegar and olive oil dressing, Tomato sauce with oil blend, Chocolate sauce with oil blend, Balsamic glaze, Yogurt and berry compote, Herb-infused cooking oil, Garlic-infused olive oil, Lemon vinaigrette

- Steps before

- Product Preparation, Ingredient Mixing, Ingredient Storage

- Steps after

- Packing, Labeling, Cooling, Quality Control

- Input ingredients

- vinegar, oil, sauce, balsamic, lemon juice, yogurt, jam

- Output ingredients

- 2 component filled package, combined sauce-oil package, vinegar-oil package, balsamic-oil package, lemon juice-oil package, yogurt-jam package

- Market info

- Capacity

- 4800 packages per hour

- Filling Accuracy

- ±1%

- Filling Method

- Volumetric filling system

- Operating Temperature

- +5 ºC to +85 ºC (standard)

- Above 90 ºC (special sealing)

- Compressed Air Usage

- 6 bars

- Electrical Connection

- 380v / 50-60 Hz (three phase)

- Consumption of Air

- 800 lt/minute at max volume and speed

- Automation

- User-friendly touch screen interface

- No Container-No Fill System

- Yes

- Filling Range (First Product)

- 5ml - 500ml (depending on model)

- Filling Range (Second Product)

- 2ml - 150ml (depending on model)

- Nozzle Feature

- Anti-dropping system

- Adjustable speed diving nozzle for foamy products

- Batch vs. continuous operation

- Batch / Inline Continuous

- CIP/SIP

- Optional CIP suitable cleaning system

- Cleaning method

- CIP / Manual

- Automation level

- PLC / Touch Screen Interface

- No container-No fill System

- Yes

- Product level control

- Automatic level control system

- Anti-dropping system

- Yes, on filling nozzles

- Corrosive resistance (e.g. acids)

- Yes

- Cleanability

- Easy disassembling with tri-clamps

- Biological compatibility

- Food hygiene standards compliant

- Abrasion resistance

- 316 L stainless steel contact parts

- Density/particle size

- Various liquid and viscous products

- Container type

- Various sizes and shapes

- Food Hygiene Standards

- Compliant

- Control panel type

- User friendly touch screen interface available in different languages

- Discharge method

- No container-No fill System

- Control panel type

- Touch screen interface available in different languages

- Customization of filling nozzles

- Interchangeable for liquids and viscous products

- Hopper options

- Optional double jacketed hopper with agitator

- Cleaning system options

- Optional C.I.P. suitable cleaning system