Industrial dough proofing systems

Optimize your bakery’s efficiency with customizable proofing systems designed to fit any space, ensuring consistent dough quality for a variety of bread and pastry products.

Proofs and Conveys Dough Products

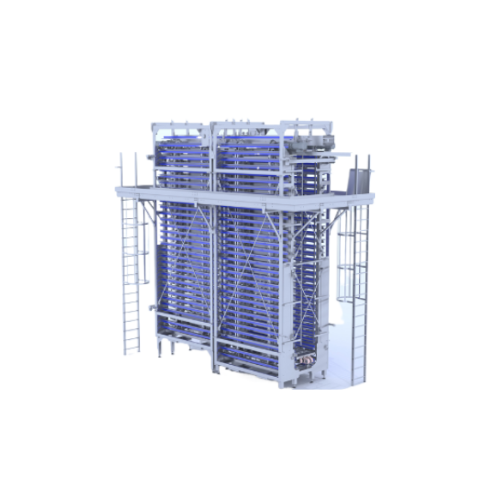

NewCap offers customized proofing solutions including the Step Proofer, Racetrack Proofer, and Step Proofer Multi Deck, designed to enhance bakery production lines. Featuring a compact design, these systems efficiently utilize vertical space while minimizing floor footprint. The Step Proofer uses a paternoster principle with up-going and down-going sections, ideal for varying capacities and baking forms. The Racetrack Proofer offers a flexible configuration adaptable to room constraints for lower capacity needs. The Step Proofer Multi Deck utilizes stacked conveyors and an elevator system to handle long-sized baking forms or large peel boards, following a FIFO unloading principle. These systems suit a wide range of dough products, including bread loaves and pastries, with options for continuous and flexible operation. Customizable for specific production environments, NewCap proofing systems promise reliable performance and seamless integration.

Benefits

- Optimizes space by utilizing vertical capacity, freeing up valuable floor area.

- Enhances product quality through consistent and controlled proofing times.

- Adapts to various production scales, from small artisanal setups to large-scale industrial operations.

- Minimizes manual intervention with automated conveyor loading and unloading.

- Supports a wide range of dough products, expanding production versatility.

- Applications

- Dough products, Bakery products, Peel boards, Baking forms

- End products

- Baguettes, Sourdough bread, Pizza bases, Bread loaves, Rolls, Pastries, Ciabatta, Brioche, Artisan bread, Focaccia

- Steps before

- Mixing, Dough Preparation, Kneading, Pre-shaping

- Steps after

- Baking, Cooling, Decorating, Packing

- Input ingredients

- dough, baking forms, peel boards

- Output ingredients

- proofed dough, proofed products

- Market info

- Design

- Solid and compact

- Footprint

- Minimal floor space

- Capacity

- High to low production capacity

- Operation principle

- Paternoster principle

- Suitable product types

- Baking forms or peel boards

- System flexibility

- Flexible alterations to fit room

- Proofing time management

- FIFO principle

- Deck layout

- Multi Deck with conveyors

- Product type

- Dough products on large peel boards

- Working mechanism

- Paternoster principle

- Integrated steps

- Proofing process

- Batch vs. continuous operation

- Batch / Inline Continuous

- Automation level

- Manual / PLC

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Type of baking forms

- Varied sizes

- Product types

- Dough products

- Machine footprint

- Compact

- Proofer type

- Step / Racetrack

- Shape and design

- Paternoster principle

- Capacity

- High / Low

- Footprint efficiency

- Utilizes building height, minimal floor space

- Configuration

- Multi Deck

- Proofer design

- Step, Racetrack, Multi Deck

- Capacity options

- High and low capacity

- Shape configuration

- Adjustable to fit room

- Footprint design

- Compact design

- Integration possibilities

- Suit production lines