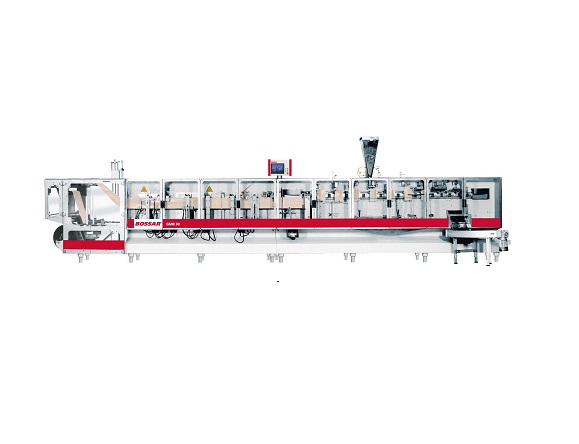

HFFS Machine for Large or Heavy Pouches

Traditional pouch-forming machines can struggle to maintain the position of the packaging through the filling process, resulting in a slower throughput and more rejected pouches. A machine specifically designed to effectively handle larger volumes and weights ensures maximum efficiency with perfect results.

Pouch filling machine for liquids or solids in large formats up to 15kg

The GMB Series from Bossar has been designed from the ground up to meet the challenges posed by large format and heavyweight flexible pouch packaging.

Key to the GMB’s success is the patented transport system. Unlike traditional walking beam transport system, the GMB utilises mechanical grippers on a chain or linear carousel. This unique system holds the pouch perfectly in place throughout the entire filling and sealing process, handling weights of up to 15kg.

Suited to hygienic production environments, the GMB features an autoclave function for sterilizing pre-made pouches or films. With up to 4 filling stations, it’s fully suitable to fill low-acidity food like pet food, fish, liquid soups, sauces, gravies, precooked meals, vegetables, pâté and more, as well as a wide range of non-food items.

GMB machines can be fitted with up to 4 work stations for functions including product filling, gas or steam injection, pouch stretching or the installation of accessories such as re-closable systems and valves. This allows them to be tailored to your exact requirements.

All machines are equipped as standard with two top sealing groups allowing the effective sealing of all packaging types, including the thick films most commonly used for large format packing of liquids, solids and frozen items.

Offering production speeds of up to 80 units per minute, the GMB series can handle pouch sizes up to 460mm x 500mm and volumes up to 15,000cc. All this while keeping operating noise to a class-leading sub-70dB, thanks to its patented linear gripper carousel system.

Benefits

- Designed specifically for large-format packaging with perfect results

- High throughput with lower reject rates means rapid ROI

- Able to seal even the thickest films used for the largest formats

- Wide range of options includes different closures and steam injection