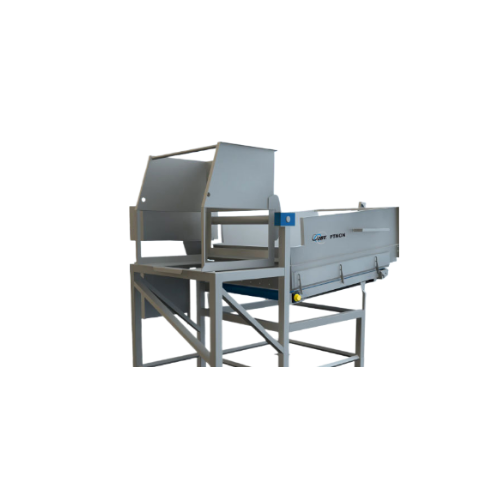

Electric bin tipper system for food processing

Achieve consistent product flow and minimize manual handling with this advanced tipping system, designed to efficiently transfer and empty solid food products, enhancing productivity and integration in high-speed operations.

Transfers and Empties Bulk Food Products

The FTNON Bin Tipper System from JBT offers a highly customizable solution for efficient handling and emptying of bulk food products such as lettuce leaves, diced tomatoes, and vinaigrette dressings. This electrically driven system operates by rotating bins up to 175 degrees, ensuring complete product transfer while accommodating various bin heights. It’s designed to seamlessly integrate with existing conveyor systems, enhancing automation and reducing labor costs in food processing lines. The system features outfeed conveyors equipped with adjustable speeds controlled via a sophisticated stainless steel control panel, allowing operators to optimize throughput. Built with stainless steel surfaces, the system offers enhanced durability and ease of cleaning, minimizing contamination risk and maintenance efforts. With the ability to tip and transfer up to 2,200 lbs of product, the system supports continuous high-speed operations, making it ideal for vegetable, oil, sauce, and ready meal processors seeking to improve line efficiency and hygiene.

Benefits

- Enhances line efficiency with seamless bin integration and automated operation.

- Minimizes downtime with easy assembly and hygienic, low-maintenance design.

- Optimizes product handling, reducing waste through thorough 175-degree bin rotation.

- Offers flexible processing with customizable bin height and conveyor speed settings.

- Supports high capacity operations, managing up to 2,200 lbs per cycle.

- Applications

- Ready meals, Soups, Sauces, Potatoes, Fresh produce, Oils, Dressings, Vegetables, Seasonings

- End products

- Vegetable broth, Pre-packaged salad, Olive oil, Alfredo sauce, Tomato soup, Potato flakes, Lettuce leaves, Vinaigrette dressing, Barbecue sauce, Potato wedges, Marinara sauce, Vegetable mix for stir-fry, Ranch dressing, Diced tomatoes, Canola oil

- Steps before

- Infeed, Sorting, Loading

- Steps after

- Outfeed, Conveying, Portioning, Slicing

- Input ingredients

- fresh produce, vegetables, potatoes, food products

- Output ingredients

- processed vegetables, processed potatoes, processed food products, emptied bin contents

- Market info

- JBT is known for manufacturing innovative industrial machinery and solutions, particularly in the food processing and air transportation sectors, renowned for their advanced technology, reliability, and customer-focused engineered-to-order solutions tailored to specific industry needs.

- Bin Rotation Angle

- Up to 175 degrees

- Material

- Stainless Steel

- Bin Capacity

- Up to 2, 200 lbs

- Bin Size

- 122 cm x 102 cm x 102 cm

- Outfeed Conveyor Width

- 1, 500 mm (59")

- Outfeed Conveyor Length

- 1, 400 mm (55")

- Outfeed Height

- 600 mm (24")

- Automation

- Electronically driven, optional pneumatic knocker system

- Cleaning Method

- Easy disassembly for cleaning

- Control Panel

- Stainless steel, intuitive interface

- Conveyor Speed Control

- Adjustable speeds via frequency inverters

- Working mechanism

- Electronic rotation up to 175 degrees

- Automation level

- Intuitive control panel

- Batch vs. continuous operation

- Batch / Inline Continuous

- Changeover time

- Minimal, due to easy disassembly

- CIP/SIP

- Manual, designed for easy cleaning

- Flexibility of Use

- Personalized configurations, adjustable bin height

- Cleaning method

- Manual, easy access design

- Integration

- Seamless integration into existing lines

- Abrasion resistance

- High

- Cleanability

- Stainless steel surfaces for ease of cleaning

- Corrosive resistance (e.g. acids)

- Stainless steel construction

- Biological compatibility

- Food-grade stainless steel

- Bin Size

- 122 cm x 102 cm x 102 cm (48” x 40“ x 40”)

- Bin Rotation Angle

- Up to 175 degrees

- Material

- Stainless Steel

- Bin Height Options

- Adjustable to accommodate different bin heights

- Control Panel Type

- Stainless steel with intuitive interface

- Knocker System

- Optional with pneumatic cylinders

- Outfeed Conveyor

- Double or single with adjustable speeds

- Integration Possibilities

- Seamlessly integrates with existing processes

- Rotation Capability

- Up to 175 degrees