Cryogenic coating tumbler for ready meal components

Achieve precise and consistent coating of substrates like seafood and vegetables in your production line with cryogenic technology, enhancing product quality and reducing waste with efficient, high-speed processing.

Coats, Freezes, and Mixes Food Products

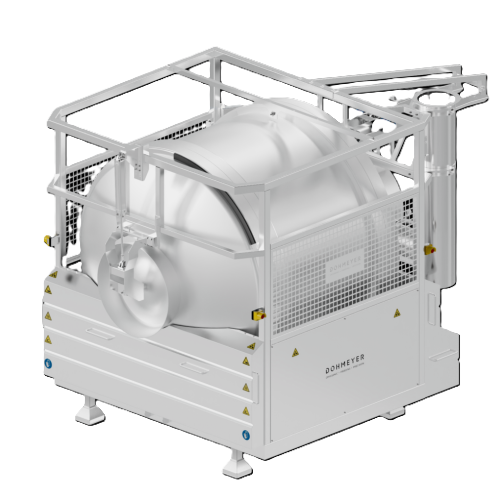

The Coating Tumbler from Dohmeyer is designed for food manufacturers seeking precise and versatile cryogenic coating solutions. This equipment specializes in evenly coating and freezing various products such as seafood, vegetables, and meats. Utilizing a programmable logic controller, it allows flexibility with multiple recipes and ensures batch consistency. The tumbler integrates advanced nozzles and injection systems, supporting up to 200% coating by weight, while minimizing product breakage and fines production. With batch sizes ranging from 50 to 800 kg, it accommodates different production scales. Swift discharging within 36 seconds and integration into existing lines enhance operational efficiency. The cryogenic process also reduces energy consumption, improving cost-effectiveness. Available in food-grade materials, it meets industry standards for hygiene and safety. Maintenance is streamlined with easy access to internal components, ensuring minimal downtime. The Coating Tumbler offers customization options to meet specific operational needs, supported by Dohmeyer’s engineering expertise.

Benefits

- Enhances product quality with precise, even coating and quick freezing.

- Minimizes production waste, reducing fines and breakage during processing.

- Increases operational efficiency with swift product discharge in under 36 seconds.

- Adapts to varying production scales with customizable batch sizes.

- Lowers energy costs through an optimized cryogenic coating process.

- Applications

- Seafood, Potatoes, Convenience food, Pasta, Meat, Ready meal components, Vegetables, Free rolling products

- End products

- Battered shrimp, Breaded fish fillets, Glazed vegetables, Marinated chicken pieces, Coated potato wedges, Popcorn chicken, Pasta salads

- Steps before

- Emulsification, Grinding, Preparing substrates

- Steps after

- Individually Quick Freezing (IQF), Packing

- Input ingredients

- seafood, vegetables, meat, potatoes, pasta, free rolling products

- Output ingredients

- IQF added value product, cryogenic sauce coated products, seasoning coated products

- Market info

- Dohmeyer is renowned for manufacturing advanced cryogenic equipment, specializing in ultra-low temperature applications for various industries, including pharmaceuticals and food processing. They are recognized for their innovation, quality, and customer-focused engineered-to-order solutions.

- Automation

- PLC-controlled

- Batch size

- 50 to 800 kg

- Nominal volume

- 500 to 8800 liter

- Discharge time

- 36 seconds

- Coating application

- Up to 200% in weight

- Working mechanism

- Cryogenic coating

- Batch vs. continuous operation

- Batch

- Automation level

- Programmable Logical Controller

- Coating efficiency control

- Up to 200% in weight

- Discharge speed

- Swift, within 36 seconds

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product type

- Seafood, Vegetables, Meat, Potatoes, Pasta

- Batch size

- 50 to 800 kg (500 liter to 8800 liter)

- Discharge method

- Swift, prevents segregation

- Control panel type

- Programmable logical controller

- Control panel type

- Programmable Logical Controller (PLC)

- Integration possibilities

- Customizable Recipes

- Batch size

- 50 to 800 kg

- Coating capacity

- Up to 200% by weight

- Discharge time

- Within 36 seconds