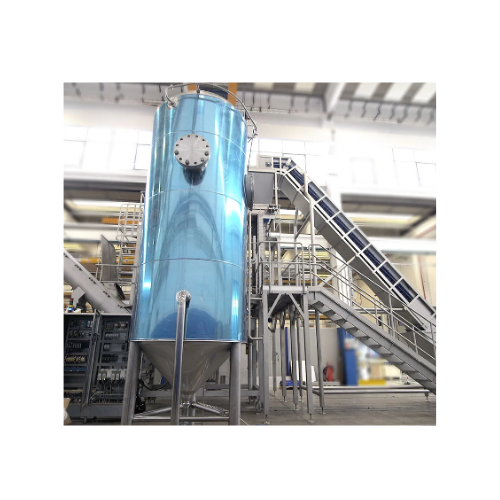

Tomato peeler

Efficiently handle tomatoes and vegetables with advanced peelers designed for high-speed operations, ensuring precise peeling and reduced energy consumption.

Peels and Processes Tomatoes and Vegetables Efficiently

The Vesuvio Millenium from CFT Group is an advanced steam peeler tailored for large-scale food processing facilities, specifically in tomato and vegetable sectors. It features a pressurized chamber with a rotor, ensuring efficient and gentle peeling for high-quality output. This machine stands out due to its ability to preserve the natural consistency and sensory qualities of tomatoes while minimizing energy consumption through low peeling temperatures. It operates continuously at high speeds, processing up to 2,200 tons of tomatoes per day, with dual steam and water peeling options for maximum efficiency. The user-friendly TSP peeler complements the Vesuvio Millenium by offering automated operation, precision control, and efficient juice recovery, handling capacities of 240 to 1,500 tons per day. Additionally, the Steam Peeler Geyser excels in peeling carrots and potatoes, delivering uniform results and maintaining hygiene with steam sterilization. These peelers integrate seamlessly into existing production lines, are constructed with durable stainless steel for longevity, and support enhanced operational efficiency with adjustable parameters and an intuitive electric control interface.

Benefits

- Enhances product quality by preserving the natural consistency and sensory attributes of produce.

- Increases operational efficiency with high-speed, continuous processing up to 2,200 tons per day.

- Reduces energy usage with low peeling temperatures and optimized steam flow.

- Minimizes maintenance costs with durable, easy-to-clean stainless steel construction.

- Provides flexibility and precision in production with adjustable parameters and automated control systems.

- Applications

- Potatoes, Vegetables, Tomatoes, Carrots

- End products

- Carrot strips, Mashed potatoes, Carrot slices, Canned tomatoes, Frozen potato cubes, Tomato paste, Diced tomatoes, Sliced potatoes

- Steps before

- Receiving, Washing, Sorting

- Steps after

- Sterilization, Pasteurization, Aseptic filling, Packaging

- Input ingredients

- tomatoes, carrots, potatoes

- Output ingredients

- peeled tomatoes, peeled carrots, peeled potatoes, high-quality peeled products

- Market info

- CFT Group specializes in manufacturing engineered-to-order equipment for the food and beverage industry, renowned for its innovative processing and packaging solutions, focusing on sustainability and advanced technology.

- Capacity

- 48 - 2, 200 tons/day

- Automation

- Fully automatic

- Heating temperature

- 106-108 °C

- Product handling

- Delicate

- Peeling method

- Steam / Dual steam and water

- Material

- Stainless steel / Galvanized steel

- Control panel

- Touch-screen monitor / PC

- Operation pressure

- Pressurized chamber

- Steam flow

- Parallel steam flow

- Working mechanism

- Abrasive and steam peeling

- Integrated steps

- Dual steam and water peeling

- Automation level

- Fully automatic / Manual

- Changeover time

- Effortless process management

- Energy efficiency

- Low peeling temperature reduces energy consumption

- Process control

- Independent adjustment of temperature and dwell time

- Cleaning method

- Automatic washing system

- Batch vs. continuous operation

- Continuous operation

- CIP/SIP

- Automatic washing system

- Abrasion resistance

- High

- Corrosive resistance (e.g. acids)

- Stainless steel components

- Biological compatibility

- Not applicable

- Cleanability

- Easy to clean with automatic washing system

- Heat Sensitivity

- Low heat penetration

- Product Uniformity

- Uniform results for different sizes and shapes

- Material Type

- Tomatoes, carrots, potatoes

- Control panel type

- Electric control panel with a touch-screen monitor or PC

- Frame material

- Stainless steel or galvanized steel

- Control panel type

- Touch-screen monitor or PC

- Material

- Stainless steel or galvanized steel