Sausage filling line for natural, collagen, and peel-off casings

Streamline your sausage production with rapid casing changes under 2 seconds, seamless integration for continuous high-speed operation, and precise portioning for consistent quality in every link.

Links, Fills, and Portions Sausages Efficiently

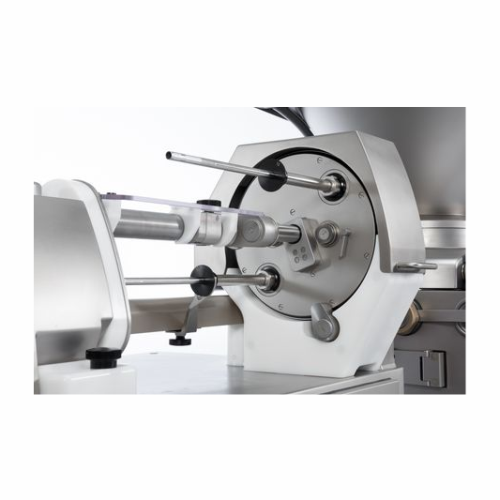

The PVLH 228 Plus from Handtmann is a high-performance sausage filling and linking line tailored for diverse food processing needs. This system excels in minimizing casing change times to under 2 seconds, thanks to its dual linking nozzles and revolving head, enhancing throughput and efficiency. It handles a variety of products such as wieners, kielbasa, and vegetarian sausages with precision, delivering portions accurate to the gram. Built for continuous, high-speed operation, the PVLH 228 Plus seamlessly integrates into existing production lines, offering automation via state-of-the-art EtherCAT technology. Its ergonomic design includes an adjustable hanging unit for optimized smoke stick utilization. This equipment is suitable for meat producers, convenience food manufacturers, and more, supporting industries from meat processing to vegan products. Additionally, its digital setup assistant facilitates quick product changeovers, while integrated smoke stick scales reduce product giveaway, making it a robust solution for maximizing production efficiency.

Benefits

- Increases production output with rapid casing changes under 2 seconds.

- Enhances portion accuracy, reducing material waste and product giveaway.

- Streamlines setup and operation, requiring minimal manual adjustment.

- Supports diverse product ranges, from meat to vegan sausages, expanding production capabilities.

- Optimizes ergonomic conditions with adjustable components, improving operator comfort and efficiency.

- Applications

- Sausage and meat products, Baked goods, Soups, Sauces, Combined products, Vegan and meat substitute, Salads, Pet food, Confectionery, Vegetarian, Stews, Fish and seafood, Dairy products

- End products

- Wieners, Cocktail sausages, Vegetarian sausages, Weisswurst, Pet food meat sticks, Kielbasa, Fresh sausages, Hot dogs, Vegan sausage products

- Steps before

- Grinding, Mixing, Massaging

- Steps after

- Hanging, Smoking, Packing

- Input ingredients

- natural casing, collagen casing, peel-off casing, sausage mix

- Output ingredients

- wieners, kielbasa, cocktail sausages, weisswurst, hot dog, fresh sausage, vegetarian/vegan sausage products, pet food

- Market info

- Handtmann is known for its engineering expertise in providing high-quality, tailor-made processing solutions, particularly in the food industry, with a strong reputation for innovation, reliability, and technical support in portioning and filling equipment.

- Speed

- up to 2, 000 port./ min.

- Setup Time

- Less than 2 seconds casing change time

- Automation

- State-of-the-art EtherCAT technology

- Output Capacity

- High production output

- Portion Accuracy

- Accurate to the gram

- Portion Lengths

- 25 mm

- Casing Diameter Range

- 13 to 50 mm

- Changeover Time

- Short conversion times during product changes

- Linking Nozzles

- 2-nozzle revolver

- Automation level

- State-of-the-art EtherCAT technology

- Batch vs. continuous operation

- Continuous

- Changeover time

- Under 2 seconds

- Cleaning method

- Easy operation

- Natural casing compatibility

- Yes

- Collagen casing compatibility

- Yes

- Artificial casing compatibility

- Yes

- Cleanability

- Easy operation

- Casing types

- Natural, collagen, peel-off casing

- Footprint

- Compact

- Control panel type

- Touchscreen

- Discharge method

- Automatic

- Nozzle type

- 2-nozzle revolver

- Casings types support

- Natural, Collagen, Peel-off

- Control panel type

- Easy operation interface

- Integration possibilities

- State-of-the-art EtherCAT technology

- Setup time

- Minimum setup times

- Product change conversion

- Short conversion times with digital setup assistant

- Hanging unit

- Individually adjustable height