Mayonnaise Manufacturing Equipment

Find innovative production technology for making mayonnaise and connect directly with world-leading specialists

Mayonnaise is created by blending oil with eggs, and then flavoring with vinegar, mustard, herbs, and spices. The eggs are a natural emulsifier that creates a uniform mixture. Ingredients are pumped into mayonnaise manufacturing equipment. First, a dynamic mixer maintains the desired level of emulsification of the mixture, which then moves on to packaging and bottling once reaching a satisfactory consistency.

Tell us about your production challenge

Improving your production process with mayonnaise processing equipment

The production process of mayonnaise is fairly straightforward. You prepare a stainless steel mixing tank with water and vinegar, to which ingredients may be pumped from other tanks. This emulsification mixer blends the ingredients into a uniform consistency. Once adequately combined, your mayo is ready to be pumped to your bottling equipment. Your filled bottles are capped, sent to your labelling machine, and ready for distribution.

Fundamentals of food safety

The production of mayonnaise employs the use of raw eggs, so food safety becomes a major point of concern due in particular to the risk of salmonella poisoning. All eggs used in the production of mayonnaise must be pasteurized. This process uses heat of approximately 60 °C to kill any bacteria present without cooking the egg. The mayonnaise making machine and equipment used in this step are pasteurization machines that significantly accelerate this process at an industrial scale.

Pasteurized eggs that are refrigerated should remain so, or condensation may stimulate bacterial growth into the egg. Eggs at room temperature, however, do not require refrigeration after pasteurization. In addition, maintaining pH below 4.1 will further help to prevent salmonella growth. Failure to ensure proper food safety of your egg ingredients can compromise the safety of your mayonnaise.

Eggs, the exceptional emulsifiers

The importance of eggs in the production of mayonnaise lies in their properties of emulsification. Traditionally mayonnaise contains only the yolk portion of the egg, but low-fat varieties will typically use the whites instead. The yolk emulsifies so well due to a protein called lecithin, but egg whites also have emulsifying properties from their albumin content, so either or both will suffice for this purpose.

The egg proteins envelope minute portions of vinegar, allowing it to disperse evenly within an oil base. The water-loving heads of lecithin are drawn to the vinegar, while the fat-loving tails extend into the oil. Any insoluble ingredients may be combined in this way to achieve uniform consistency. Interestingly, turmeric and saffron are prohibited from use in mayonnaise production for their ability to mimic the color of egg yolk.

No eggs, no problem! Making vegan mayonnaise

Producing vegan mayonnaise comes with the challenge of achieving a similar emulsion to traditional mayo without the eggs. To do this, any emulsifier will work, but soy-derived lecithin is a common substitute. Vegan mayonnaise may also be produced in partial emulsions that separate slowly. If your mayo has separated, a quick mixing will reconstitute the ingredients into a uniform mixture for consumption. Without the eggs, this may not be considered true mayonnaise, as is the case in the United States. Even so, it is often indistinguishable in taste and texture.

Mayonnaise: the modifier of many mixtures

A variety of products incorporate mayonnaise for its rich flavor and creamy texture. Considering that mayo is mainly just a mixture of oil and eggs, it can be substituted for them in any recipe. Cakes and cookies are one such example. Mayonnaise can provide a protective coating to lock in moisture when cooking, or be used to create a more complex emulsion such as creamy salad dressings like creamy italian, or sauces such as mustard.

Fry sauce is a combination of mayonnaise and ketchup, spicy mayonnaise is a common ingredient in Asian cooking, and Aioli is essentially mayonnaise with garlic and other dried spices. Non-food uses also abound as a lubricant, cleaning agent, burn treatment, hair treatment, cosmetics and others. Though simple to make, mayonnaise is an exceptionally versatile ingredient.

Processing steps involved in mayonnaise making

Which mayonnaise technology do you need?

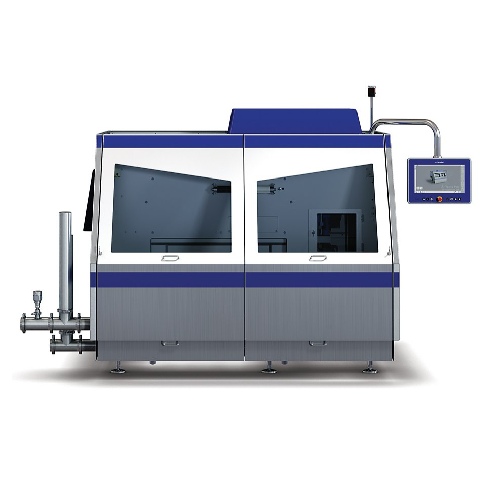

High shear emulsifier for mayonnaise production

Streamline your production of high-quality emulsions with this high-capaci...

High shear emulsifier for food and pharmaceutical products

Optimize your production line with precise emulsification, ho...

Heat exchangers for efficient heat transfer in industry

Achieve precise temperature control across diverse viscosities wi...

Precise liquid cooling solution for food processing

Ensure high-quality preservation of flavors and textures in liquid fo...

Continuous nut paste production line

Elevate your production efficiency with a versatile preparation line designed to seaml...

Continuous mustard production line

Optimize your condiment production with precision-engineered systems capable of transfor...

Cheese blending and heating line for processed cheese

Optimize your processed cheese production with a solution that seam...

Continuous caramel production line

Optimize your caramel production with seamless integration, achieving precise fat meltin...

Industrial cooker for sauces and stews

When producing diverse culinary delights such as sauces and stews, achieving even he...

Continuous heat exchanger for soups and sauces

Optimize your soup and sauce production with a continuous heat exchanger th...

Efficient cooling and cooking systems for food processing

Streamline your production with integrated cooling and cooking...

Industrial cutting system for fine emulsions

Optimize your production line with precision cutting and emulsifying, ensurin...

Vacuum deaeration system for mustard and liquid detergents

Ensure optimal product quality by effectively removing air fr...

Cleaning systems for food, pharmaceuticals, and cosmetics

Ensure optimal hygiene and safety with advanced cleaning syste...

Continuous caramel process line

Optimize your continuous food processing with an engineered-to-order line tailored for preci...

Continuous cheese line

Achieve precise temperature control and seamless product transitions with this equipment, ideal for en...

Continuous mustard line

Streamline mustard production with high-capacity continuous processing that reduces air pockets and e...

Continuous tahina production line

Streamline your tahina production with precise grinding and controlled cooling, ensuring ...

Vacuum de-aeration unit for liquid to pasty products

Optimize your product consistency and stability with continuous de-a...

Colloid mill for emulsifying and wet milling applications

Achieve precise mixing and grinding with our colloid mill, des...

Vertical colloid mill for emulsifying and homogenizing

Optimize your production line with precise particle size reduction...

Multistage mixers for emulsions and dispersions

Experience efficient emulsification and dispersion processes with this ver...

Turnkey food and beverage processing solutions

Optimize your production line with integrated processing systems designed t...

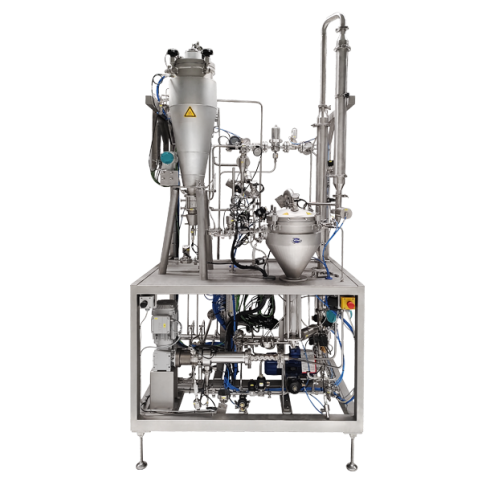

Mayonnaise production system

Ensure precise emulsification for low to full-fat mayonnaise and similar cold emulsions with a ...

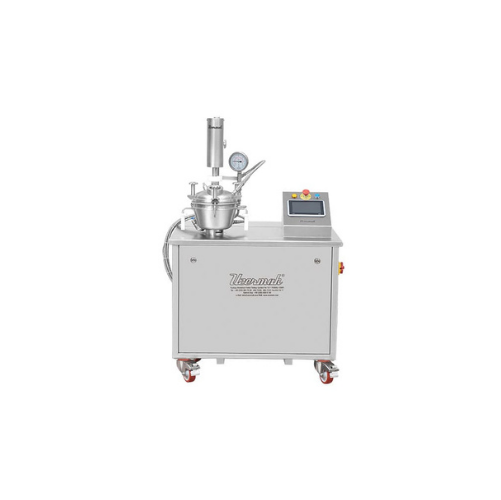

Compact production unit for liquid food products with varied viscosities

Streamline your batch production with this ver...

Scraped surface heat exchanger for food processing

Efficiently handle temperature-sensitive food products with a compact ...

Aseptic thermal processor for high viscosity products

Optimize your processing of high viscosity products with precise te...

Semi-liquid weigh filler for edible oils & fats

Achieve precise weigh filling of semi-liquids while minimizing product was...

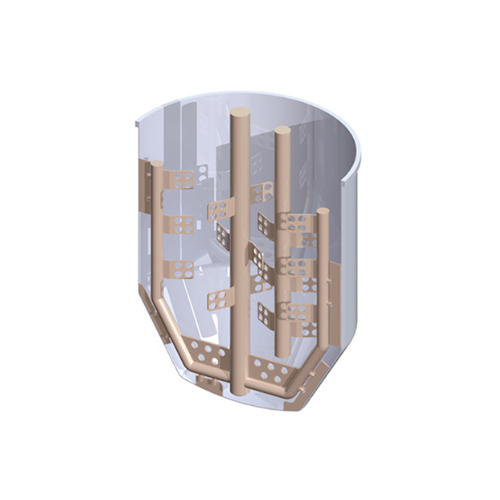

Atmospheric blending vessel for r&d activities

Optimize your liquid blending processes with this versatile vessel, designe...

Direct steam infusion for high spore kill rate in sensitive food products

Achieve rapid, efficient sterilization and m...

Tube filling machine for cosmetics and food products

Achieve precise and efficient packaging with this advanced twin-head...

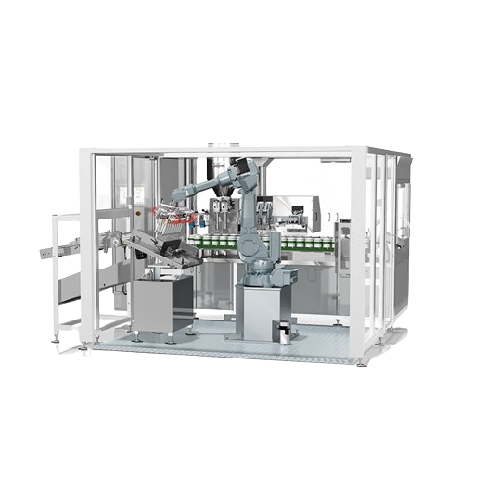

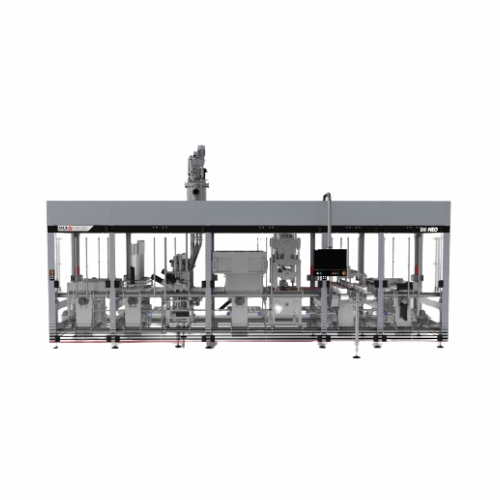

Pick & place robot for packing tubes in boxes

Efficiently streamline your packaging line with this compact case packer, de...

Tube filling station for plastic, laminate, and aluminum tubes

Efficiently seal and fill various tube materials, ensurin...

Oil and fat filling system for industrial use

Optimize your production line with this precise filling solution, designed t...

Professional dosing system for creams and sauces

Streamline your production with precise dosing of creams and sauces, tail...

Vacuum mixing system for emulsion and homogenization

Achieve seamless emulsion and homogenization with precision: this sy...

Precision weighing tank for liquid and dry ingredient blending

Enhance your production line with precision control over ...

Industrial powder blender

Optimize your production with precise dry blending, ensuring efficient mixing processes and seamle...

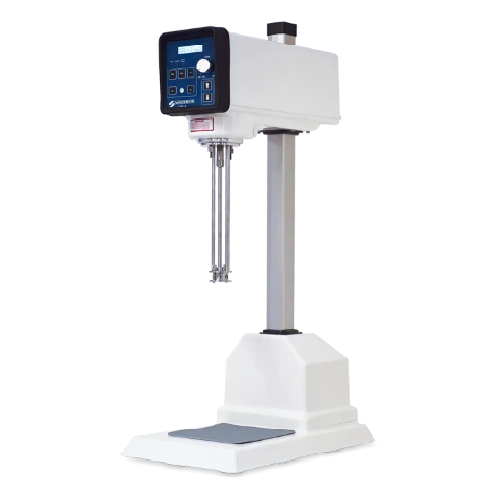

Industrial mixer for high shear mixing and emulsifying

Enhance your production line efficiency with versatile high shear ...

Inline high shear mixing for dairy and condiments

Streamline your production line with innovative inline high shear mixin...

Batch mixer for dry and liquid ingredients

Achieve efficient blending of diverse ingredients with high shear mixing to str...

High-shear inline mixer for lump-free products

Achieve consistent texture and prevent clumping in liquid and powder blends...

Pre-mixer for dissolving powders fast

Quickly dissolve powders without lumps or “fisheyes,” ensuring a smooth a...

Multifunctional mixer for high volume batches

Efficiently handle complex mixing, emulsifying, and homogenizing tasks with ...

Industrial melting tank for diverse manufacturing applications

Optimize your production with this versatile melting tank...

Blender for high viscous products

Tackle high-viscosity challenges with an advanced blending solution designed for efficien...

Customized oil storage tank for industrial use

Enhance production efficiency and ensure seamless integration with customiz...

Large insulated oil storage tank

Ensure optimal temperature control for sensitive liquids like oils, sauces, and creams with...

Heating solution for vegetable and meat products

Achieve efficient heating and optimal heat transfer for sauces and dairy ...

Cip dosing and water unit for industrial cleaning

Elevate your plant’s hygiene with this system, designed for seaml...

Conical buffer tank for hygienic dairy and food processing

Achieve efficient processing of high-viscosity products with ...

Powder dissolver for large liquid quantities

Achieve uniform powder blending swiftly with a vacuum-assisted system that pr...

Ultra high temperature treatment system

Achieve extended shelf life and product stability with ultra high temperature treat...

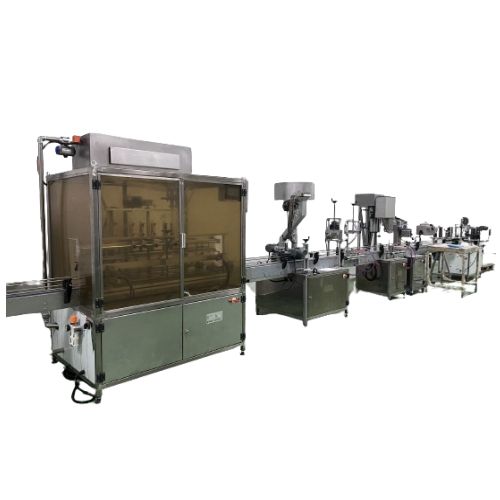

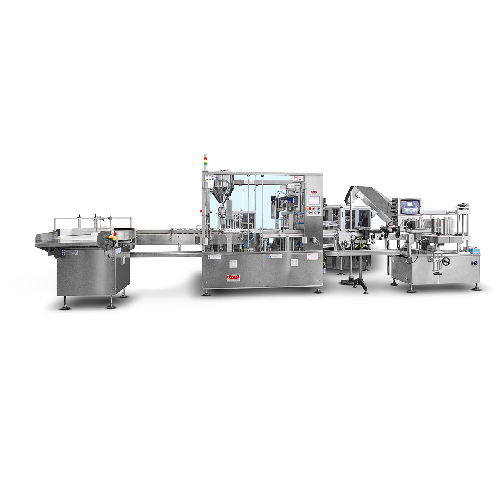

High capacity filling line for jars and bottles

Need to streamline your packaging line? This high-capacity solution proces...

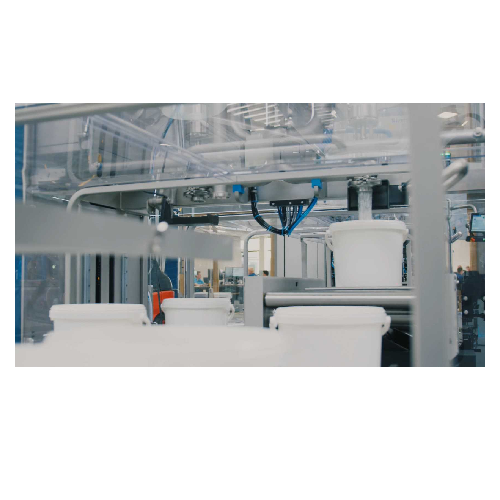

Large container filling line

Optimize your production line with a seamless solution for efficiently filling large containers...

Semi-automatic capper for twisting and screwing metal and plastic caps

Effortlessly achieve precise cap tightening with...

Volumetric filler for packaging liquids and semi-solids

Optimize your filling process with precision control and adaptabl...

2-head liquid and viscous product filling system

Streamline your filling operations with precision and versatility designe...

8 head liquid and viscous product filling system

When precision and speed are crucial, this 8 head filling machine ensures...

Automatic capping system for varied cap types

Enhance your packaging line efficiency with a high-speed capping machine des...

In-line disperser for high-volume liquid processing

Streamline your emulsification process with powerful rotor-stator hom...

Tank bottom mixer for high viscosity applications

Achieve seamless emulsification and homogenization of high-viscosity pr...

In-line high shear mixing solution

Achieve precise emulsification and particle size reduction with high shear capabilities,...

High shear vertical mixer for dispersion and emulsification

Achieve seamless emulsification and homogenization in divers...

Agitators for mixing tanks

Optimize mixing operations with versatile agitators designed for various viscosities and fluid ty...

Steam jacketed kettle for cooking sauces and dressings

Enhance your sauce production with a steam jacketed kettle that en...

High-speed drift-dwell motion doypack forming system

Optimize your liquid packaging efficiency with a dual-motion system ...

Form fill and seal machine for portion packs

Streamline your portion packaging with a compact system that efficiently form...

Form fill and seal solution for dairy portion packs

Optimize your production with precision portion packing, reducing mat...

Filling and sealing system for pre-formed cups

Experience seamless integration of hygienic filling and sealing with adapta...

Automatic tubefiller for food and dairy products

Achieve precise dosing and seamless tube filling with high-speed efficien...

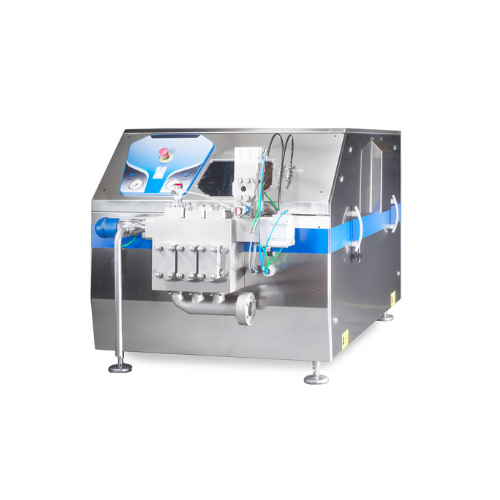

Industrial homogenizer for food and pharmaceutical applications

Ensure product consistency and stability with high-press...

Magnet for emulsion technology for lump-free blends

Achieve perfectly smooth and stable emulsions in a single pass with a...

Steam-heated hemispherical bottom cookers for sauce production

Streamline your sauce and condiment production with multi...

Liquid food filling solutions

Maximize efficiency in your packaging line with versatile filling machines designed for precis...

Conical powder mixer for uniform powder blending

Achieve consistent powder blending while preserving the integrity of deli...

Automated cleaning in place (cip) systems for beverage processing

Optimize your production with automated CIP systems t...

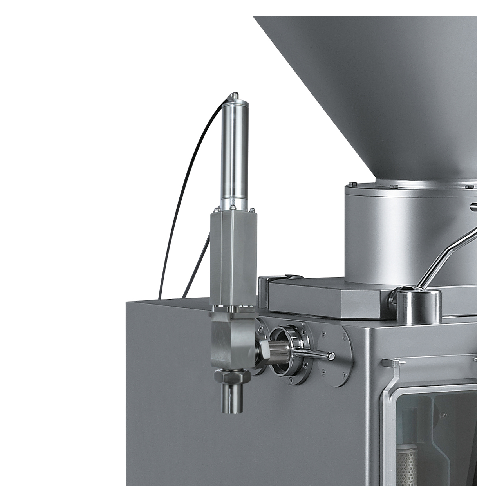

In-line mayonnaise emulsifying system

Streamline your sauce and dip production with a system designed for efficient emulsif...

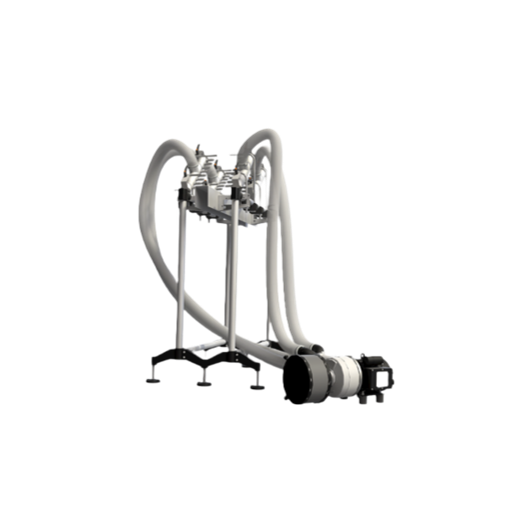

Dilute-phase conveying solution for powder handling

Efficiently transfer powders and granules with robust leak containmen...

Inline high-shear mixer for powders and liquids

Achieve efficient mixing and homogenization in your production line with a...

High-capacity inline mixer for dairy and beverages production

Achieve a rapid and homogeneous mix in high-capacity produ...

Mixer for low to medium viscosity products

Optimize your mixing, dosing, and homogenization processes with a versatile mix...

High-shear mixer for high viscosity products

Achieve consistent, homogeneous mixtures of high-viscosity products with a ve...

Ultra-high shear mixer for emulsification and homogenization

Optimize your production with ultra-high shear mixing, acce...

Bigbag discharge system for food, chemical, and pharmaceutical industries

Ensure precise and dust-free handling of bul...

Bigbag filling system for powder and bulk materials

Ensure precise and dust-free bigbag filling with this versatile syste...

Dense-phase powder conveying system

Optimize your powder processing with a system designed to handle abrasive and fragile m...

Transfer hopper with stainless Pd pump for food processing

Eliminate spillage and maintain continuous flow with a positi...

Horizontal screw loader for food processing

Optimize your production flow with a smooth-loading solution designed to effic...

Compact food emulsion and reduction system

Achieve precise control over product texture and temperature with a compact sol...

High-precision rotary weight filler for edible oils and sauces

Achieve exceptional filling precision with solutions desi...

Automatic piston fillers for liquid products

Optimize your liquid filling process with high-precision piston fillers, engi...

High-capacity filler and closer for pumpable products

Efficiently handle pumpable, flowable, and pasty products with this...

High-pressure homogenizer for dairy and food production

Optimize your product consistency and stability with a high-press...

Industrial homogenizers for high-pressure applications

Optimize homogenization with high-pressure solutions designed for ...

Industrial homogenizer for food and beverage applications

For manufacturers seeking consistent quality, this homogenizer...

Vacuum deaerator for elimination of gases

Optimize your product quality by eliminating occlusive gases with this advanced ...

Homogenizer for high viscosity emulsion and dispersion

Achieve unparalleled dispersion and emulsification with a system d...

Industrial vacuum mixer and reactor for liquids

For manufacturers needing precise blending and stability, this advanced va...

Colloidal mill for fine grinding and homogenisation

Optimize your liquid and semi-solid processing by achieving precise p...

Pneumatic dosing system for dense and semi-dense products

For precise dosing of dense and semi-dense liquids, this pneum...

Linear filler for preformed containers

Streamline your packaging process with a compact solution that ensures precise filli...

Automatic food cooking oil bottling solution

Ensure precise volumetric filling for a range of liquid products, enhancing y...

Flexible bag-in-box filler for liquid and viscous products

Optimized for flexibility and efficiency, this bag-in-box fil...

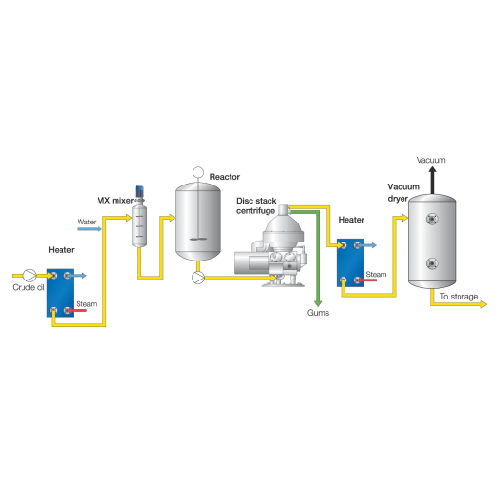

Degumming systems for edible oils

Achieve superior oil quality with innovative degumming systems that effectively eliminate...

Double-wall scraped surface heat exchanger

Achieve high-capacity processing with gentle handling for shear-sensitive produ...

Scraped surface heat exchanger for viscous products

Efficiently handle challenging viscosities and heat-sensitive product...

Scraped surface evaporator for high-viscosity materials

Efficiently concentrate high-viscosity and hard-to-handle materia...

Scraped surface heat exchanger for high-pressure applications

Handle high-viscosity and particulate-rich products with p...

Emulsion processing system for homogenizing solids into liquids

Achieve precision in emulsifying and homogenizing proces...

Benchtop mixer for lab-scale product development

Easily scale up your formulations with precise and repeatable lab-scale m...

Inline continuous mixer for dairy and beverage processing

Achieve precise emulsification and particle size reduction for...

Inline wet mill for mayonnaise emulsions

Eliminate the challenges of achieving stable, uniform emulsions in your sauces and...

Pilot scale mixers for product development and small production runs

Optimize your mixing processes with precision cont...

Low-shear portable mixer

For processes demanding strict hygiene, this mixer eliminates rust and chipped coatings by offering ...

High shear emulsifier for hygienic applications

Achieve precise emulsification and consistent mixture quality with enhance...

Efficient tube filler and sealer

Optimize your production line with a semi-automatic tube filling and sealing solution, desi...

Dual asymmetric centrifugal mixer for epoxy and slurry mixing

Achieve precise mixing and consistency in your formulation...

Automatic positive displacement bottle filler

Streamline your liquid filling operations with precision and flexibility, id...

Semi-automatic volumetric piston filler

Achieve precise filling of diverse liquids and viscous products while minimizing wa...

Accurate net weight filling for liquid and semi-liquid products

Ensure precise filling of diverse viscosities, from thin...

Automatic capper for dual head o-ring chuck

Ensure precise cap application with dual-head precision, handling various bott...

Centrifuge for drying fragile salads

Achieve consistent drying of delicate leafy greens with minimal damage, enhancing prod...

Mixing tank for soups, sauces, and dressings

Streamline your soup and sauce production with advanced mixing technology des...

Industrial mixing tanks for liquid, slurry, and gas dosing

Optimize your production with versatile mix tanks, designed t...

Industrial block melt system for butter and chocolate

Efficiently transition solid blocks of butter, chocolate, or waxes ...

Layer pad for agitating retorts in food processing

Efficiently secure and process irregularly shaped containers in retort...

Aseptic bag filler for bulk containers

Eliminate spoilage events and ensure sterility in high-speed filling of bulk aseptic...

Twin screw pump for viscous media

Streamline your production with a twin screw pump that effortlessly handles viscous media...

High shear mixer for dairy and personal care products

Achieve consistent emulsification and stable homogeneity with high ...

High shear test mixers for developing new products

Streamline product development with high shear test mixers, allowing y...

Microparticulation unit for whey protein processing

Enhance your dairy and food formulations with optimized whey protein ...

Laboratory homogenizers for nanoparticles and emulsions

Tackle the challenge of achieving consistent nano-scale dispersio...

Laboratory homogenizer for scaling nisox-valve benefits

Achieve reliable scaling from lab to production with this precise...

Complete filling and closing line for food containers

Optimize your production line with a versatile solution that ensure...

Inline disperser for food production

Quickly achieve stable, agglomerate-free dispersions and emulsions with minimal manual...

Horizontal flat pouching solution for foods and chemicals

Achieve precision in pouching liquids and powders with high-sp...

Planetary mixers for baking and food industries

Achieve precise mixing and consistency across a range of products with adv...

Emptying systems for high viscosity fluids and pastes

Efficiently empty high-viscosity fluids and pastes with precision, ...

Complete mixing systems for industrial applications

Optimize your production efficiency and product consistency with adva...

Complete mixing solution for food, cosmetics, and chemical industries

Optimize your production line with a system that ...

Inline mechanical homogenizer for food processing

Achieve precise particle size and uniform texture in your emulsions and...

Multifunctional industrial food mixer

Efficiently handle complex food processing tasks from mixing to homogenizing with a m...

Multifunctional cheese and sauce processor

Optimize your production of sauces, dressings, and confectionery fillings with ...

Multifunctional industrial mixer for processed cheese and sauces

Optimize your batch production with a versatile solutio...

Compact food depositor for direct container use

Streamline your depositing process with a versatile solution that handles ...

Rotary cup filling and closing system

Maximize production efficiency with a system that offers precision filling and secure...

Commercial food mixers for versatile culinary applications

Streamline your food production with mixers and kneaders desi...

Medium volume bottle and jar filling system

Efficiently manage filling operations for diverse liquid and semi-dense produc...

High shear mixer for emulsions and dispersions

Achieve precise emulsification and dispersion with advanced high-speed mixi...

Tubular heat exchanger for food processing

Optimize energy consumption and ensure unparalleled food safety during heat tre...

Industrial homogenizer for liquid food applications

Achieve unparalleled product consistency and quality with high-speed ...

Homogenizer for high-capacity food processing

Achieve superior emulsification and suspension handling with this high-press...

Ultra-high temperature processor for premium liquid foods

Achieve superior product quality and flexibility with advanced...

High shear mixer for dairy and beverage industry

Achieve consistent product quality with a high shear mixer, enabling seam...

Batch mixer for soft drinks ingredients

Effectively manage diverse ingredient formats with a high-performance mixing system...

Industrial homogenizer for dairy and beverage applications

Enhance product quality and reduce operational costs with a h...

High-pressure homogenizer for dairy and beverage products

Achieve optimal product consistency and extend shelf life with...

Batch dissolver for sugar or dextrose

Efficiently dissolve crystalline substances like sugar and dextrose with precision, e...

Versatile filling system for aseptic packaging

Achieve seamless integration in high-speed aseptic packaging with this flex...

Manual monoblock for filling and capping jars

Optimize your jar filling and capping processes, even with high-temperature ...

Manual system for filling and capping jars

Ideal for efficiently handling liquid and semi-dense products, this manual syst...

Accurate volumetric filler for liquid and semi-dense products

Achieve precise dosing and filling of various liquid and s...

Bench-top piston filler for liquid and semi-dense products

Optimize your filling precision with a versatile piston fille...

Automatic line for filling and capping spouted pouches

Streamline your production line with high-speed filling and cappin...

Inline blender for liquid ingredients

Optimize your production line with seamless liquid blending, enhancing flavor consist...

Colloid mill for particle size reduction and emulsification

Achieve precise particle size reduction and stable emulsions...

High-shear mixer for emulsions, dispersions, and foams

Achieve precise emulsions and dispersions effortlessly with high-s...

Shear pumps for continuous on-line dispersion

Effortlessly achieve consistent shearing and mixing with versatile shear pum...

Scraped surface heat exchangers for high viscosity products

Ideal for continuous processing, these heat exchangers effic...

Scraped surface heat exchanger for high-viscosity products

Designed for handling high-viscosity products, this system en...

Soymilk processing plant

Enhance your plant-based production with our tailored soymilk processing plants, designed to efficie...

High pressure homogenizer for food and beverage processing

Optimize your production line with a versatile high-pressure ...

Hygienic tanks for various processing needs

Achieve optimal processing and storage with customizable hygienic tanks, desig...

Pilot plants for small-scale viscous product processing

Optimize your product development with pilot plants designed for ...

Process tanks for mixing, cooking, and cooling applications

Efficiently tackle viscous product challenges with advanced ...

Laboratory in-line mixer for precise mixing and reproducibility

Achieve precise laboratory-scale mixing with rapid proce...

In-line ultra sanitary mixer for pharmaceutical and food applications

Enhance your liquid formulations with precision m...

High shear lab mixer for laboratory work and r&d

Achieve unparalleled precision and consistency in laboratory and pilot-sc...

Pilot scale batch mixer for small scale production

Achieve precise control and consistency in small-scale production with...

Sanitary high shear mixers for pharmaceutical production

Achieve unparalleled hygiene and efficiency in your mixing proce...

Bottom entry mixers for high viscosity products

Optimize your production line with mixers designed to handle both high and...

Automated production line for ground meat products

Enhance your meat processing efficiency by seamlessly integrating grin...

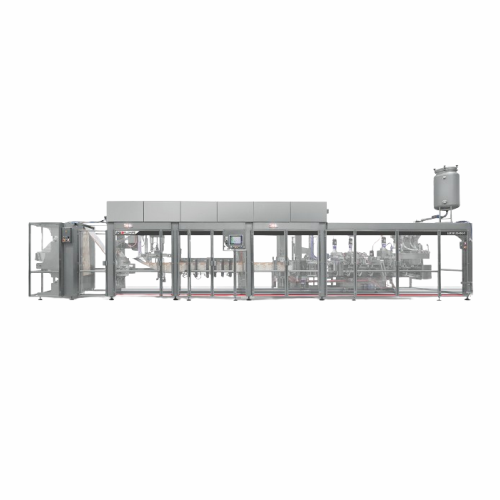

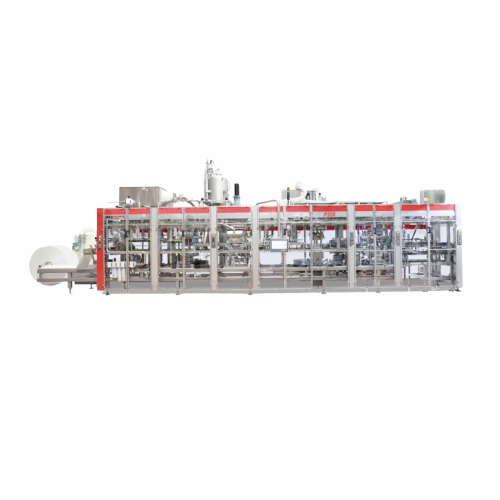

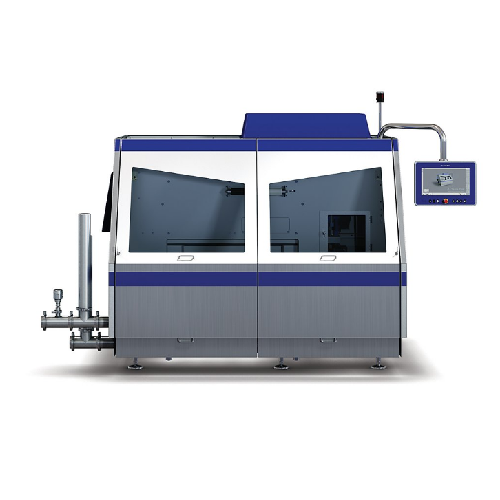

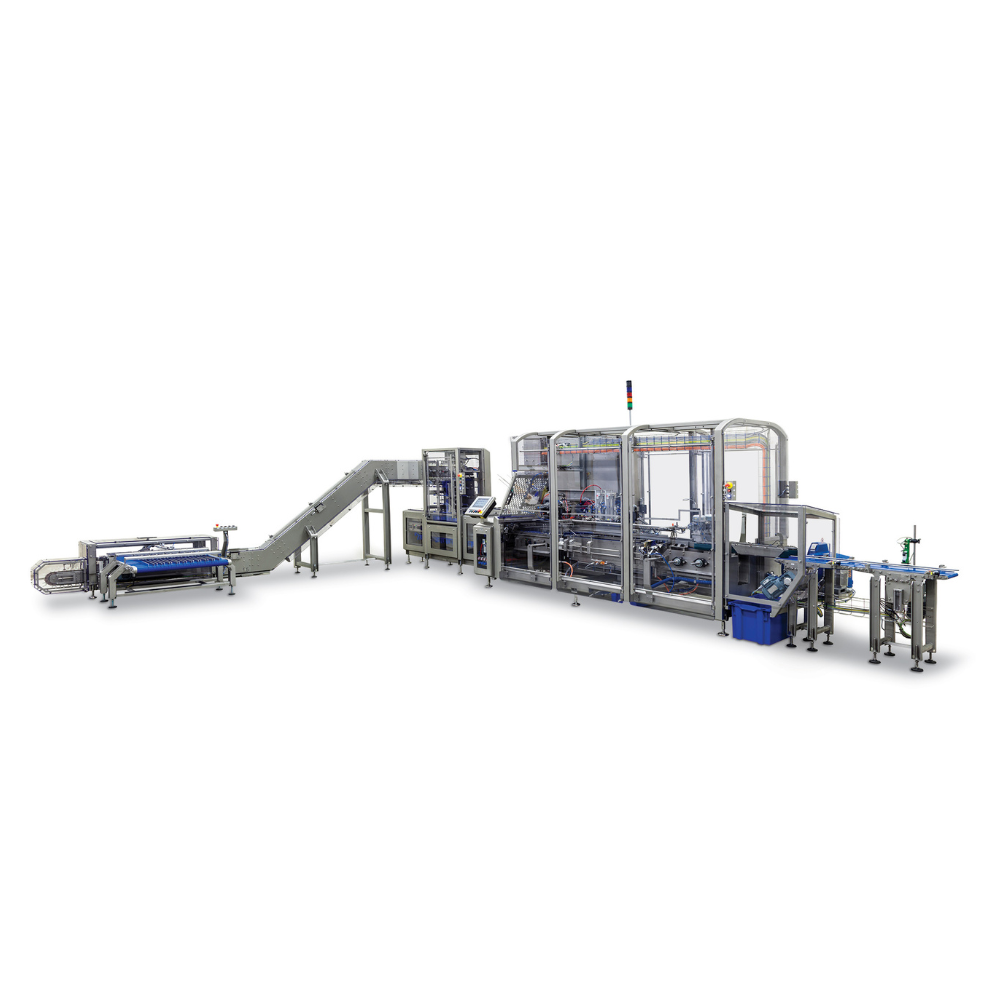

Mayonnaise production line

Streamline your high-capacity mayonnaise production with precise mixing, emulsifying, and pasteur...

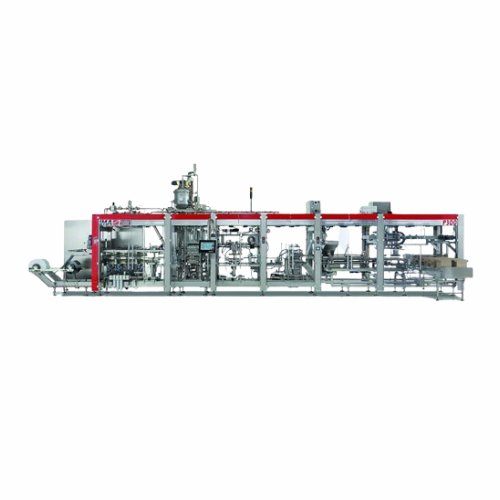

Automated mayonnaise and dressing production line

Ensure the consistent quality of your mayonnaise, dressings, and sauces...

Blow-fill-cap solution for low/medium batch production

Streamline your production line with a compact blow-fill-cap syste...

Ketchup manufacturing line

Streamline your sauce production with precision-engineered efficiency, allowing for seamless reci...

Industrial solutions for beverage mixing and carbonation

Optimize your beverage production with precise mixing and carbon...

Vacuum process system for food product mixing and emulsifying

Optimize your production of sauces, dressings, and condime...

High pressure plunger pump for continuous food processing

Achieve consistent texture and quality in spreads and sauces w...

Vertical dosing valve for accurate food portioning

Ensure precision in portioning liquid and semi-liquid food products wi...

All-in-one system for making emulsions

To make smooth batches of mayonnaise or ketchup you need to use process equipment fo...

Homogenization and emulsifying system for fine foods

Texture and consistency are critical to foods with delicate composit...

Pilot plant homogeniser

From food to pharma, homogenization is an essential step in the production process that provides unif...

Monobloc filler and capper

If you have separate filling and capping stations you may experience lower throughput rates due t...

Autoclave sterilizer for food cans and jars

An autoclave is a must-have machine for canned food production lines. It perfo...

Temperature-treatment mixer for bakery & gastronomy

The production of creams, sauces, ragouts, ready-to-bake, and sim...

Small-scale laboratory dispersing machine

Developing and validating new processes requires reliable and highly versatile e...

Bottle filling and capping monobloc

Spillage and overfilling are common problems in most production lines for bottled produ...

Industrial vacuum cooker

Batch cookers can be highly inflexible and inefficient, relying on maximum fill levels to operate we...

Pilot ultrasonic extractor

In the herbal medicine industry, an ultrasonic extractor is a valid alternative to conventional e...

Automatic filling machine for sauce

Traditional sauce filling units can struggle to maintain a high quality of output in ca...

Pipeline metal detector for sauces

Ensuring liquid and viscous products such as sauces, soups, juices and meat are contamin...

Vacuum based homogenizer

When producing liquid and viscous products such as mayonnaise, sauces, dressings and ketchup it’s vi...

Universal Mixer and Cooker for Sauces

Sauce cookers and mixing machines have traditionally been designed to suit one proces...

Colloid mill

For creating extremely fine emulsions and high quality dispersions a high pressure homogenizer is often chosen. ...

High-pressure homogenizer

When processes call for homogenized emulsions with extremely fine particle sizes the traditional t...

Stickpack Machine

If you are looking to pack your product into stick packs from 17 x 40 mm to 100 x 200 mm in size, you may b...

High-speed unscrambler for small bottles

Large-scale production of smaller volume bottled product needs a gentle, accurate ...

Shrink sleeve applicator - 800 per minute

High speed, in-line shrink sleeving systems require dual head capability with hi...

Advanced auto-steam shrink system

Design and development of shrink sleeves could be made much easier if small batches of sa...

Premium steam tunnel for sleeve application

Maximum flexibility in terms of pressure, temperature and ramp setting and adj...

Shrink tunnel for applying sleeves to different containers

Maximum flexibility is required when setting pressure and dir...

Corundum disk mill

Wet milling and grinding of viscous liquids or pastes containing solid particles such as peanut butter,mus...

Dispersing machine for emulsions and suspensions

Equipment operating under the rotor/stator principal is often employed wh...

Economic dispersing machine for emulsions and suspensions

For products of medium viscosity and relatively consistent par...

Dispersing machine for very fine emulsions and suspensions

For continuous high performance mixing of solid and liquid ra...

Ultra-fine dispersing machine for emulsions and suspensions

Producing the finest micro-emulsions and suspensions require...

Cone mill machine

When your raw materials include agglomorated suspensions of grainy or crystalline solids and your process n...

Empty bottle shape, colour and size sorting system

Accurate bottle sorting system that differentiates between the bottles...

Smart Industrial Sauce Cartoning System

Large volume producers of sauces and ready meals continuously pack different produc...

Batch processing system for emulsions and suspensions

Emulsions enhance foods with a creamy mouthfeel and richer flavors....