In-line disperser for high-volume liquid processing

Streamline your emulsification process with powerful rotor-stator homogenization, delivering consistent particle size reduction and high shear mixing for optimal product consistency and stability.

Processes and Homogenizes Emulsions and Suspensions

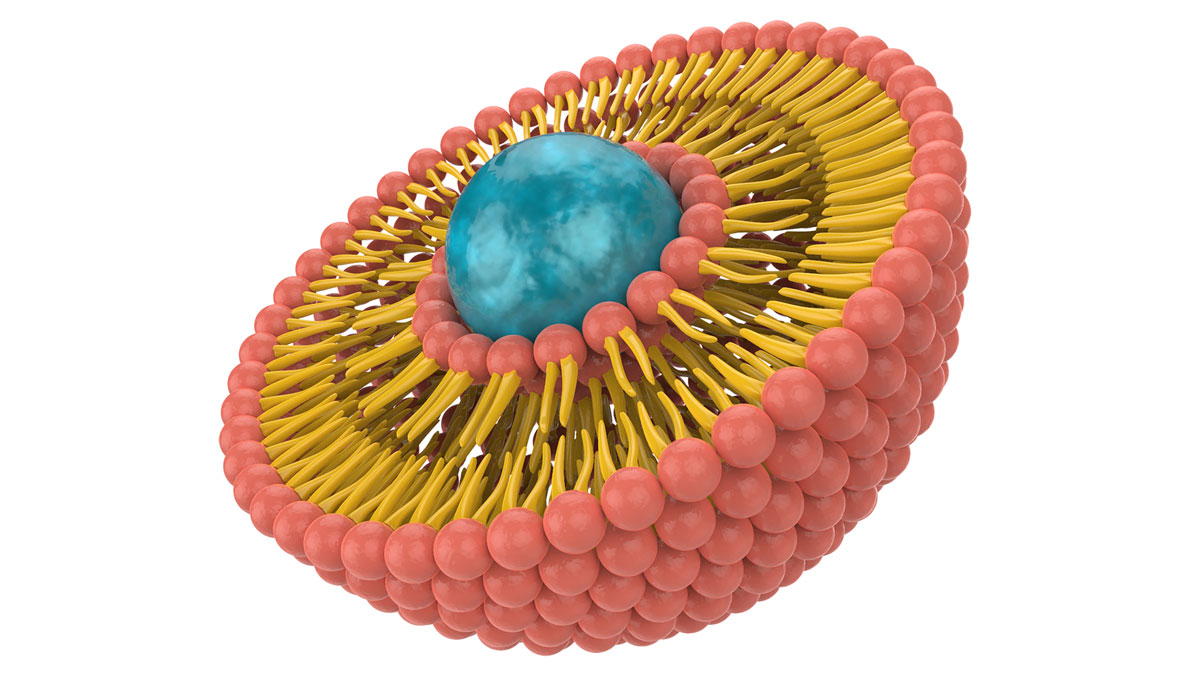

The MEGATRON® MT / MT-V Series from Kinematica AG is an advanced inline rotor-stator homogenizer engineered for efficient mixing, emulsifying, and dispersing across multiple industries including pharmaceuticals, chemicals, and food production. This equipment is renowned for its precise three-stage chamber design that ensures uniform processing of liquid and slurry products. Ideal for creating fine emulsions such as vaccine adjuvants, polymer emulsions, and silicone dispersions, it boasts a throughput capacity of up to 150,000 L/h. Featuring wear-free three-phase motors with RECO® speed control, the MEGATRON® series integrates seamlessly into existing production lines, offering robust build quality with high-grade stainless steel and customizable sealing systems. Compliance with CE, CIP, SIP, and 3A standards underscores its suitability for rigorous applications, while an electropolished surface ensures easy maintenance and sanitation.

Benefits

- Enhances product consistency with precise emulsification and dispersion.

- Reduces operational costs with wear-free motors and RECO® speed control.

- Customizable sealing options ensure compatibility with a wide range of processes.

- Streamlines cleaning and maintenance with electropolished surfaces.

- Meets stringent industry standards for pharmaceutical and chemical applications.

- Applications

- Chemicals, Food, Suspensions, Cosmetics, Emulsions, Life sciences, Dispersions, Pharmaceuticals

- End products

- Vaccine adjuvants, Fruit purees, Topical creams, Dna/rna suspensions, Protein emulsions, Nanoemulsions, Paint emulsions, Liposomal formulations, Polymer emulsions, Face lotions, Silicone dispersions, Mayonnaise

- Steps before

- Mixing, Blending, Emulsification, Formulation preparation

- Steps after

- Quality control, Formulation analysis, Filling, Packaging

- Input ingredients

- fluids, samples, emulsions, dispersions, suspensions

- Output ingredients

- homogeneous emulsions, homogeneous dispersions, homogeneous suspensions, homogenous material systems

- Market info

- Throughput Volume

- 3000–128, 000 L/h

- Motor Power

- 4 kW three-phase motor

- Speed Range

- up to 12, 000 min-1

- Circumferential Speed

- max. 41 m/s

- Processing System

- Inline product processing

- Shaft Seal

- One- or three-stage rotor/stator / Four different rotor/stator variants

- Materials

- High-grade stainless steel 316L

- Surface Finish

- Electropolished, Ra =< 0.8

- Standards

- CE, CIP, SIP, 3A

- Working Mechanism

- Inline Homogenizer

- Integrated Steps

- Single- and Multi-stage Work Chambers

- CIP/SIP

- CE, CIP, SIP

- Batch vs. Continuous Operation

- Inline Continuous

- Process Control

- Customer Requirements Adaptable

- Cooling/Heating Options

- Available

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Work chamber type

- Single-stage and multi-stage

- Cooling/heating jacket

- Available as standard

- In/outlet connections

- Various types available

- Rotor/stator variants

- Four different types

- Shaft sealing

- Single- or double-action floating ring seals

- Shaft sealing type

- Single- or double action floating ring seals

- Work chamber stages

- One- or three-stage

- Rotor/Stator variants

- Four different variants

- In/outlet connections

- Various options available

- Cooling/heating jacket

- Available as standard

- Sealing materials

- Product-compliant

- Process control

- Customer requirements-based