Degumming systems for edible oils

Achieve superior oil quality with innovative degumming systems that effectively eliminate impurities, reduce operational costs, and enhance overall yield in edible oil processing.

Efficiently Degums and Purifies Edible Oils

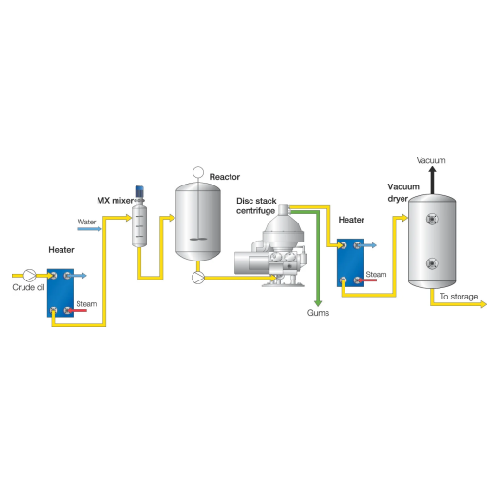

Alfa Laval’s degumming systems are designed to enhance the quality and yield of edible oils by effectively removing hydratable and non-hydratable gums, phospholipids, proteins, and other impurities. These systems utilize a combination of disc stack centrifuges, mixers, and plate heat exchangers, allowing for continuous, high-speed processing that integrates seamlessly into existing production lines. Ideal for edible oil refineries and food processing companies, these systems support a wide range of applications, producing end-products like margarine, olive oil, and soybean oil.

The equipment operates using modular, automated components that ensure operational reliability and efficiency, contributing to increased uptime and service life. By employing enzymatic, water, acid, and special degumming processes, Alfa Laval systems optimize the pre-treatment stage, minimizing gum content and operating costs while maximizing oil yield and product quality. The systems are also engineered for energy efficiency, leveraging advanced motor control to reduce energy consumption. Constructed with durable materials, the systems are built to handle demanding operational conditions, ensuring long-term performance and corrosion resistance. Customization options and engineering support are available to meet specific production needs, making Alfa Laval’s degumming systems a vital component in the edible oil refining industry.

Benefits

- Enhances oil quality and yield, reducing operational costs through effective gum removal.

- Increases production efficiency with continuous and high-speed processing capabilities.

- Lowers energy expenses via optimized motor control and modular equipment design.

- Extends system longevity and reliability with corrosion-resistant materials and robust construction.

- Offers flexibility and adaptability for various oil types and production requirements.

- Applications

- Sunflower oil, Edible oils, Fats, Animal fats, Vegetable oils, Soybean oil

- End products

- Olive oil, Mayonnaise, Lecithin, Margarine, Tomato paste, Bottled sunflower oil

- Steps before

- Extraction, Acid Conditioning

- Steps after

- Neutralization, Bleaching, Deodorization, Dewaxing, Packing

- Input ingredients

- vegetable oils, animal fats, lard, tallow, fish oil, phospholipids, proteins, carbohydrates, nitrogen compounds, chlorides, metals, insoluble impurities

- Output ingredients

- edible oil, lecithin, neutral oil, diacylglycerol, lyso-gums, free fatty acids, refined oils

- Market info

- Alfa Laval is renowned for its expertise in heat transfer, separation, and fluid handling technologies, providing innovative, energy-efficient engineered-to-order solutions for various industries including food, marine, and energy.

- Capacity

- Small, medium and large plant capacities

- Automation

- Modular and easy to install

- Degumming Method

- Water/Enzymatic/Acid/Special

- Enzyme Type

- Phospholipase C, Phospholipase A

- Centrifuge Type

- Disc stack centrifuges

- Heat Exchangers

- Plate heat exchangers

- Mixers

- Alfa Laval mixers

- Oil Type

- All types of fats and oils

- Utility Cost

- Reduction in utility costs

- Installation Type

- Standalone or integrated into existing lines

- Operational Reliability

- Raise operational reliability and efficiency

- Working Mechanism

- Disc stack centrifuge, plate heat exchangers, mixers

- Integrated Steps

- Degumming, acid degumming, enzymatic degumming, water degumming

- Batch vs. continuous operation

- Continuous

- Automation level

- Manual / PLC

- Cleaning Method

- CIP

- Temperature Control

- Controlled temperatures for certain processes

- System Flexibility

- Modular and easy to integrate

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Edible Oil Type

- Vegetable, Animal

- Integration possibilities

- Modular, stand-alone, or complete system integration

- Control panel type

- Not specified

- System configuration

- Water, enzymatic, acid, special degumming setups

- Centrifuge type

- Disc stack centrifuge, self-cleaning

- Mixing capability

- Flexible mixing type, including MX mixer