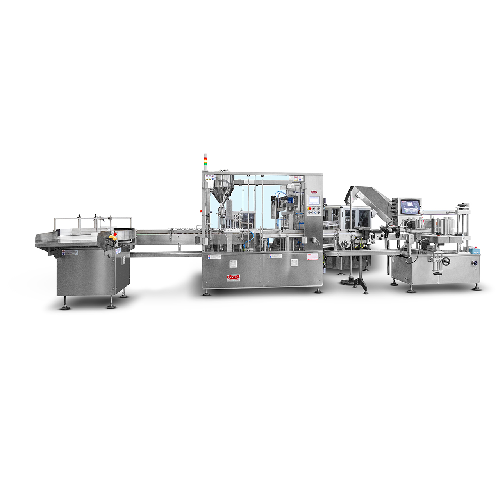

Medium volume bottle and jar filling system

Efficiently manage filling operations for diverse liquid and semi-dense products, ensuring versatile packaging solutions with seamless bottle and jar format adaptability.

Fills and Caps Liquid and Semi-Dense Products

The M100 from TGM – TECNOMACHINES is a versatile monoblock designed for medium-volume bottle and jar filling. It excels in handling liquid, dense, and semi-dense formulations such as shampoos, creams, sauces, and syrups, offering flexibility for different product viscosities and container stability. With a capacity of up to 2400 pieces per hour, the M100 efficiently manages the filling, capping, and packaging processes. Its semi-automatic operation integrates seamlessly into existing production lines, and its user-friendly design allows for quick format changes between bottles and products. The machine’s construction in stainless steel ensures durability and compliance with industry standards, making it suitable for pharmaceutical, cosmetics, food, and personal care sectors.

Benefits

- Optimizes production with up to 2400 units per hour throughput.

- Ensures product versatility, accommodating a range of liquid viscosities.

- Simplifies format changes, reducing setup time between production runs.

- Enhances production integration with semi-automatic operation.

- Maintains compliance with industry standards for pharmaceuticals and food products.

- Applications

- Liquid formulations, Dense and semi-dense products, Bottled goods, Jarred goods, Packaged liquids

- End products

- Hair gel, Olive oil, Face masks, Syrups, Honey, Mayonnaise, Body lotion, Shampoo, Tomato sauce, Liquid soap, Skincare creams

- Steps before

- Emulsification, Preparing Containers

- Steps after

- Capping, Packing

- Input ingredients

- bottles, jars, liquid products, dense products, semi-dense products, caps, undercaps, disks

- Output ingredients

- filled bottles, filled jars

- Market info

- TGM - TECNOMACHINES srl is known for manufacturing customized, engineered-to-order packaging machinery, specializing in designing and producing high-quality, efficient equipment tailored to specific customer needs in various industries.

- Filling speed

- Up to 2400 pieces/hour

- Capacity

- Medium volume production

- Filling type

- Liquid, dense, and semi-dense products

- Container type

- Bottles and jars

- Automation

- Automatic filling and loading systems

- Component Loading

- Equipped for bottle, jar, cap, undercap, disk

- Production capacity

- Up to 2400 pieces/hour

- Automation level

- Manual / PLC

- Changeover flexibility

- Simple change of bottle and product format

- Filling flexibility

- Handles liquid or dense and semi-dense products

- Packaging component management

- Bottle, jar, cap, undercap, disk

- Stability management

- Works with stable or unstable bottles

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container Size

- 50 ml – 1 L

- Container Type

- Stable / Unstable

- Filling Purpose

- Bottles and Jars

- Bottle and product format changeover

- Simple

- Loading systems

- Bottle / Jar / Cap / Undercap / Disk