High-pressure homogenizers for dairy and juice processing

Ensure superior texture and stability in your liquid formulations with precise high-pressure homogenization, reducing particle size and enhancing material efficacy across production stages.

Enhances Product Stability and Uniformity

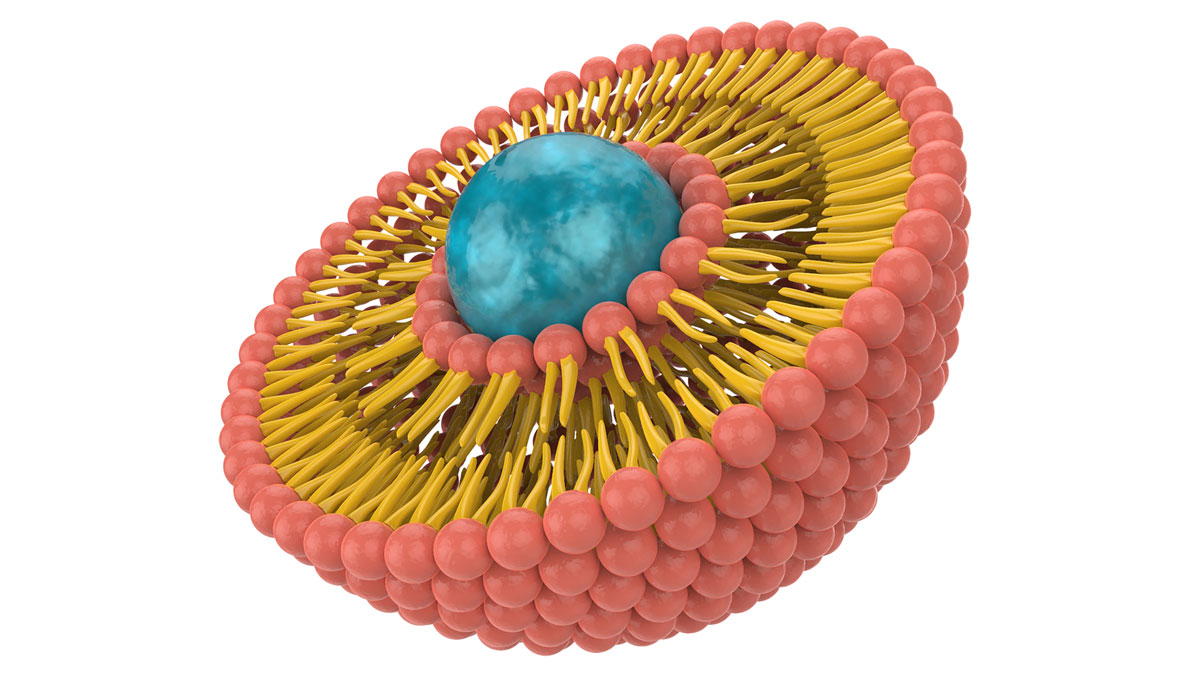

The HST series of high-pressure homogenizers, including models like the HST HL 2 and HST HLI90, offer versatility across various industries, including food, pharmaceuticals, cosmetics, and chemicals. Employing a unique turbulent and laminar force application within a narrow gap, these homogenizers break down fat globules and stabilize emulsions, improving product consistency and extending shelf life without over-reliance on stabilizers. Ideal for producing fresh milk, infant formula, and lubricants, they offer capacities ranging from 300 to 80,000 liters per hour. Engineered for efficient integration, these homogenizers feature aseptic designs for sterile processing, and some models are equipped with ATEX compliant options for explosive atmospheres. Constructed with material adaptability in mind, HST offers high-strength stainless steel or ceramic components, ensuring longevity and compatibility with a wide range of substances. Optimization for reduced pulsation and noise is achieved through custom piston geometry and a special HST coating that minimizes abrasion. With energy-efficient designs and comprehensive engineering support for customization, HST homogenizers promise reliable operation and easier maintenance with options for integrated PLC control systems.

Benefits

- Enhances product quality with consistent texture and stability for diverse applications.

- Increases operational efficiency by handling up to 80,000 liters per hour.

- Reduces maintenance costs through durable materials and abrasion-resistant components.

- Supports sterile processing with aseptic design options, eliminating contamination risks.

- Offers energy savings with optimized motor controls and reduced water consumption.

- Applications

- Chemicals, Intravenous emulsions, Dyes, Textures, Nanosomes, Food industry, Cosmetics, Cell disruption, Pigment dispersions, Beauty creams, Ointments, Lubricants, Emulsions, Resins, Liposomes, Special drinks, Latex, Pharmaceuticals

- End products

- Luxury beauty moisturizers, Infant formula, Pigment dispersants, Condensed milk mix, Encapsulated nanosomes, Water-based fuel emulsions, Liposome encapsulation, Industrial wax emulsions, Ketchup consistency enhancer, Synthetic resin binders, Latex stabilizers, Fruit juice concentrates, Nutraceutical beverages, Renewable lubricants, Uht processed milk, Mixed ice cream blend, Salad dressings, Biological cell lysates, Vegetable juice concentrate, Fresh milk, Agricultural pesticides, Medical ointments, Yogurt base, Nanoemulsions, Thickening agents, Injectable dyes, Egg product stabilizer

- Steps before

- Heat Treatment, UHT Processing, Ingredient Mixing

- Steps after

- Sterilization, Aseptic Packaging, Flavor Addition, Creaming Stability Enhancement

- Input ingredients

- Fresh milk, Cream, Vegetable juices, UHT milk, Yoghurt, Baby and infant food, Condensed milk, Ketchup, Sauces and dressings, Mixed ice cream, Fruit juices, Egg products, Special drinks, Intravenous emulsions, Liposomes, Ingredients, Textures, Beauty creams, Dyes, Ointments, Cell disruption, Pigment dispersions, Lubricants, Fuels/water emulsions, Wax emulsions, Insecticides/herbicides, Resin dispersions, Nanosomes, Colours, Latex

- Output ingredients

- Stable emulsions, Evenly distributed fat globules, Improved shelf life, Enhanced flavour, Consistent texture, Creaming stability, Reduced stabiliser usage

- Market info

- HST Maschinenbau is known for its expertise in designing and manufacturing custom-engineered industrial machinery, particularly in the sectors of hydraulics and automation, with a strong reputation for quality and innovative solutions tailored to client needs.

- Capacity Range

- 5.5 - 250kW (300l/h until 35, 000l/h)

- Capacity Range

- 55-90kW (8, 000 - 14, 000l/h) and 400kW (up to 80, 000l/h)

- Capacity Range

- 3-75kW (10, 000l/h – 200bar)

- Design Options

- Aseptic / ATEX

- Noise Insulation

- Included

- Valve Type

- PLUG / PILOTED / Multigap

- Piston Material

- Standard / Chrome-plated / Ceramic / Special HST Coating

- Working mechanism

- High-pressure homogenization

- Integrated steps

- Turbulent and laminar force application

- Batch vs. continuous operation

- Continuous

- Noise insulation

- Noise insulation cladding

- Aseptic operation

- Aseptic design as an option

- ATEX operation

- ATEX design as an option

- Automation level

- Pneumatic or hydraulic valve control

- Energy efficiency

- Energy-saving Multigap valve

- Abrasion resistance

- High

- Corrosive resistance

- High-strength stainless steels, ceramics

- Biological compatibility

- Sterile water compatibility

- Cleanability

- CIP/SIP compatible

- Density/particle size

- Compatible with various viscosities and particle sizes

- Versatile industry applications

- Food, Pharmaceuticals, Chemicals

- Noise Insulation

- Noise insulation cladding available

- Design Options

- Aseptic, ATEX

- Homogenizing Valve Types

- PLUG, PILOTED, Multigap

- Control panel type

- PLC-controlled

- Valve material

- High-strength stainless steels, sintered materials, ceramics

- Piston coating

- Standard, chrome-plated, ceramic, HST special coating

- Design options

- Aseptic, ATEX

- Noise insulation

- Noise insulation cladding

- Homogenizing valve type

- PLUG, PILOTED, Multigap