Industrial dough laminator for croissants and pastries

Achieve consistently light and flaky products with precision laminating technology designed to optimize the fat and dough layering process, ensuring high-quality results in pastry production while maintaining flexibility in your processing setup.

Processes and Laminates Dough for Baked Goods

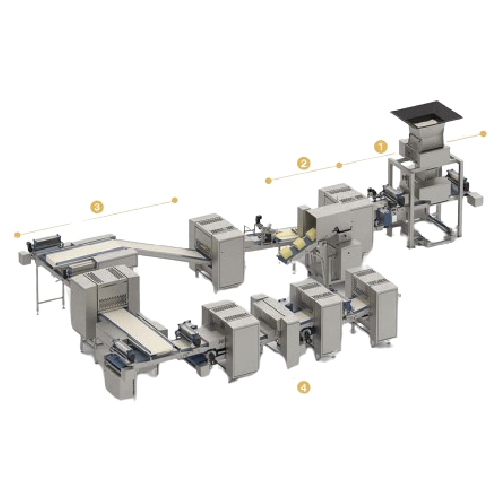

The Radini Laminator from Rademaker is engineered to enhance your bakery’s production efficiency by creating high-quality laminated dough sheets for a variety of baked goods including croissants, pastries, and artisanal breads. Specializing in precise dough and fat layer integration, this equipment operates with a modular configuration that fits seamlessly into any production line. With a capacity ranging from 250 to 1,000 kg per hour, it can scale to meet industrial demands. The Radini Laminator features an intuitive interface for easy operation, offering both semi-automatic and fully automatic processes with minimal footprint. Its robust construction ensures consistent product quality, employing either horizontal laminating or cutting and stacking methods for diverse applications. Designed with the baker’s needs in mind, it simplifies cleaning and maintenance with accessible components, while supporting customization to accommodate specific production requirements. Integrating effortlessly into existing workflows, it provides a reliable solution for producing laminated dough on both small and industrial scales.

Benefits

- Enhances product consistency with precise layer integration for superior baked goods.

- Reduces production time and manual labor with fully automated processes.

- Scales easily with modular configuration to meet growing demand without sacrificing quality.

- Minimizes operational footprint, maximizing available workspace in your facility.

- Simplifies maintenance and cleaning, reducing downtime and ensuring continuous operation.

- Applications

- Pie, Bread, Flatbreads, Laminated dough, Pizza, Croissants, Quiche, Donuts, Pastries, Bread and buns

- End products

- Glazed donuts, Viennoiseries, Pita bread, Quiche lorraine, Sourdough bread, Artisan breads, Laminated croissants, Puff pastries, Ciabatta bread, Cheese quiche, Focaccia flatbread, Fruit tartes, Lamb pies, Beignets, Pizza bases, Danish pastries, Brioche buns

- Steps before

- Pre-sheeting, Fat application

- Steps after

- Sheeting, Resting, Cooling, Block making, Make up line production

- Input ingredients

- dough, fat, butter, margarine

- Output ingredients

- laminated dough, pastries, croissants, bread, buns, donuts

- Market info

- Rademaker is known for its expertise in manufacturing industrial bakery equipment, offering engineered-to-order solutions. They have a strong reputation for innovative, high-quality machines designed for efficiency and reliability in food production.

- Working width

- 600 or 800 mm

- Capacity

- 250 up to 1, 000 kg dough per hour

- Automation level

- Manual / Automatic

- Lamination options

- Horizontal / Cutting, Stacking

- Lamination layers

- 4, 6, or 8 per section

- Modular configuration

- 2-section (L shape), 3-section (U, S, or Z shape), Inline

- Fat application method

- Manual / Automatic with Radini Fat Pump

- Fat sheet thickness

- Adjustable

- Block folding options

- 2, 3, or 4 layers

- Working mechanism

- Horizontal lamination and cutting/stacking

- Automation level

- Manual / Fully Automated

- Batch vs. continuous operation

- Inline Continuous

- Cleaning method

- Fast and easy cleaning

- Modular configuration

- L shape / U shape / S shape / Z shape / Inline

- Pre-sheeting method

- Chunker / Extruder

- Layer adjustment

- Configurable layers (3 to 8)

- Fat application

- Manual / Automatic with fat pump

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Product compatibility

- Bread, Croissants, Pastries, Donuts

- Working width

- 600 or 800 mm

- Footprint

- Small

- Modular configuration

- 2 or 3 section laminator, Inline

- Control panel type

- Intuitive interface

- Working Width

- 600 or 800 mm

- Capacity

- 250 up to 1, 000 kg dough per hour

- Lamination Layers

- 4, 6, or 8 layers

- Automation Level

- Fully automated or manual-automated combination

- Modular Configuration

- L shape, U shape, S shape, Z shape, Inline

- Laminating Methods

- Horizontal Laminating and Cutting and Stacking

- Fat Application

- Manual or Automatic (Radini fat pump)

- Control Interface

- Intuitive Operating Panel

- Sheeter Size

- Adjustable thickness

- Footprint

- Small footprint design