Forming, filling and sealing solution for cups

Maximize production efficiency and flexibility with a high-output machine designed for versatile cup forming, filling, and sealing. Ideal for producing a wide range of dairy and food products, this solution ensures precision and hygiene while adapting to varying cup shapes and sizes.

Forms, Fills, and Seals Cups Efficiently

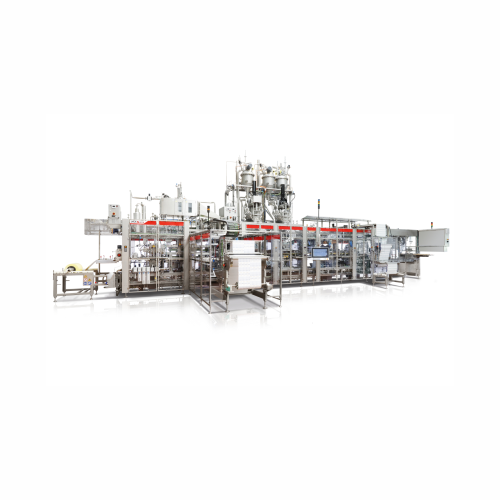

The C500 from IMA Group is an engineered-to-order Form-Fill-Seal (FFS) machine designed for the efficient production of various cup sizes and shapes, including dual cavity configurations. This high-output machine excels in handling applications ranging from yogurt and desserts to sauces and liquid formulations. The machine’s servo-driven operation ensures precise process control and integrates seamlessly into continuous, high-speed production lines. Offering a throughput of up to 57,600 cups per hour, it caters to diverse production needs with customizable processing capacities. The C500 stands out with its aseptic packaging option, complying with VDMA, FDA, and EHEDG standards to extend product shelf life without chemical preservatives. Constructed with hygiene in mind, options range from clean to aseptic classes. Featuring advanced HMI and software for user-friendly operation, the C500 supports in-line cup decoration and offers low maintenance with minimized spare parts costs. Additionally, the machine is equipped with a multi-component filling system, facilitating accurate dosing and reduced product loss. Customizations are available to suit specific processing requirements, backed by engineering support for seamless integration.

Benefits

- Maximizes production efficiency with throughput up to 57,600 cups per hour.

- Enhances product safety and shelf life with aseptic packaging capabilities.

- Minimizes maintenance costs due to its streamlined design and reduced spare parts requirement.

- Provides flexibility with a wide range of cup shapes and dual cavity options.

- Ensures precise filling and reduced product waste through servo-driven control systems.

- Applications

- Food, Sauces, Liquid formulations, Confectionery, Pasty products, Yoghurt, Desserts, Dairy

- End products

- Flavored yoghurt cups, Pudding cups, Whipped cream topping containers, Marinara sauce containers, Chocolate mousse dessert cups, Olive oil portion packs, Mashed potato cups, Fruit compote cups, Cream cheese cups, Soup cups, Barbecue sauce cups, Custard cups

- Steps before

- Pre-heating, Bottom web infeed

- Steps after

- Sealing, Labelling, Packing, Case packing, Palletizing

- Input ingredients

- PET, PP, PP multilayer, PS, PS multilayer, PVC, Paper-based lid material, Aluminium-based lid material, PET-based lid material, Heat sealable materials

- Output ingredients

- Yoghurt cups, Dessert cups, PP cups, Yoghurt cups with wrap-around labelling

- Market info

- IMA is known for its expertise in manufacturing automated packaging machines and solutions, particularly for the pharmaceutical, cosmetics, food, tea, and coffee industries, offering innovative, high-quality equipment and comprehensive customer service.

- Output Capacity

- 10, 000 to 57, 600 cups/h

- Cup Shape Variety

- Handles a wide variety of cup shapes including dual cavity

- Hygiene Class

- Clean to Aseptic

- Servo-driven Control

- Yes

- Working Width

- Optimised per production capacity

- Filling Accuracy

- Outstanding accuracy (minimizing product loss)

- Material Width

- Max. 550 mm

- Draw-off Length

- Max. 320 mm

- Forming Depth

- Max. 90 mm

- Bottom Web Materials

- PET, PP, PP multilayer, PS, PS multilayer, PVC

- Lid Material

- Paper, Aluminium, PET-based, Heat Sealable

- Cycle Speed

- 18, 000 – 57, 600 cups/h based on cup type

- Reel Diameter Bottom Web

- Max. 1, 200 mm

- Reel Diameter Lid Material

- Max. 600 mm (lateral reel feed)

- Punching Principle

- Grid

- Automation level

- Servo-driven controls

- Batch vs. continuous operation

- Inline Continuous

- CIP/SIP

- Clean, Ultra-clean, Aseptic standards

- Cleaning method

- Hygiene classes from 'clean' to 'aseptic'

- Modularity

- Modular design

- Output efficiency

- 10, 000 to 57, 600 cups/h

- Flexibility

- Handles dual cavity cups and different cup shapes

- Footprint

- Reduced footprint

- Integration with other equipment

- In-line cup decoration

- Material width

- max. 550 mm

- Forming depth

- max. 90 mm

- Bottom web

- PET, PP, PP multilayer, PS, PS multilayer, PVC

- Lid material

- Paper-, aluminium- or PET-based or other heat sealable materials

- Container type

- Cups, Dual cavity cups

- Hygienic standard

- Clean, Ultra-clean, Aseptic

- Filling purpose

- Yoghurt, Desserts, PP Cups

- Material compatibility

- PET, PP, PS, Aluminium

- Decoration options

- Labelling versions

- Machine footprint

- Reduced footprint

- Control panel type

- Enhanced HMI and software

- Discharge method

- Servo-driven functions for process control

- Material width

- Max. 550 mm

- Draw-off length

- Max. 320 mm

- Forming depth

- Max. 90 mm

- Customization Options

- In-line cup decoration, multiple filling styles

- Cup shape capability

- Handles a wide variety of cup shapes, including dual cavity

- Decoration capability

- Labelling versions

- Control panel type

- Enhanced HMI and software