Automatic tube filling for coextruded products

Maximize efficiency in high-volume production with precision co-extruding capability, transforming your multi-color tube filling process with high-speed operations that ensure consistent results in each batch.

Fills and Co-Extrudes Multi-Color Cosmetic Tubes

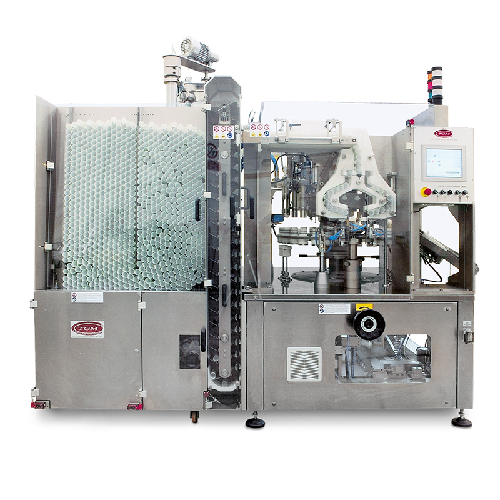

The T230 from TGM – TECNOMACHINES s.r.l. is an automatic tube filling machine known for its exceptional ability to handle co-extruded, multi-color cosmetic and pharmaceutical product applications. Designed to meet the high demands of personal care and cosmetic manufacturing, the T230 tackles production challenges with its dual-tube capability, allowing simultaneous filling of two tubes with up to three colors in various configurations like deep stripes and concentric color patterns. With a high throughput of up to 10,000 tubes per hour, the T230 serves industries requiring efficient batch processing.

Integrated into existing production lines, the T230 boasts advanced automation features, including PLC control for reliable operation and system integration, optimizing the co-extrusion process across various liquid product types. Its ergonomic design supports a large feeder system, simplifying the handling of metallic and plastic tubes, and its precise dose control reduces material wastage.

Constructed with robust materials suitable for handling chemical components, the T230 ensures durability and hygiene, easily meeting industry compliance standards. A configurable setup also offers flexibility, catering to specific product formulations and customized engineering support ensures a seamless fit for unique production environments.

Benefits

- Enhances production speed with dual-tube filling, reaching up to 10,000 tubes per hour.

- Minimizes material waste through precise multi-color co-extrusion capabilities.

- Seamlessly integrates into existing lines with PLC-controlled automation, reducing operational complexity.

- Suitable for diverse product needs across cosmetics and pharmaceutical sectors, boosting versatility.

- Supports sustainable practices with energy-efficient design and engineering.

- Applications

- Personal care products, Multi-color tubes, Cosmetic products, Co-extruded products, Pharmaceutical products

- End products

- Hair gel, Face creams, Lip balms, Sunscreen, Toothpaste, Dual-colored ointments, Ointments, Tri-color toothpaste, Body lotion

- Steps before

- Purification, Emulsification

- Steps after

- Packing, Cartoning

- Input ingredients

- co-extruded products, tubes, metal pipes, plastic pipes, 2-3 color products, 2 concentric color products

- Output ingredients

- filled tubes, coextruded 2-3 color filled products, 2 concentric color filled tubes

- Market info

- TGM - TECNOMACHINES srl is known for manufacturing customized, engineered-to-order packaging machinery, specializing in designing and producing high-quality, efficient equipment tailored to specific customer needs in various industries.

- Speed

- Up to 10000 Tubes/Hour

- Tube Diameter Range

- 10 - 42 mm (Metal)

- 10 - 50 mm (Plastic)

- Tube Length Range

- 50 - 240 mm

- Automation

- Automatic

- Filling Capability

- Co-extruded 2-3 color products

- Batch Processing

- <2 Tubes simultaneously

- Filling Method

- Ergonomic Feeder

- Automation level

- Automatic

- Batch vs. continuous operation

- Batch

- Cleaning method

- Manual

- Corrosive resistance

- Suitable for acidic and alkaline products

- Biological compatibility

- Compatible with pharmaceutical and cosmetic products

- Cleanability

- Smooth surfaces for easy cleaning

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Container size

- Diameter

- Container length

- 50-240 mm

- Batch size

- Large batches

- Machine footprint

- Compact

- Feeder size

- Very large ergonomic

- Processing capacity

- Two tubes simultaneously

- Tube diameter

- Metal

- Plastic

- 10 - 50 mm

- Tube length

- 50 - 240 mm

- Discharge method

- Automatic

- Control panel type

- PLC-controlled

- Compact footprint

- Yes