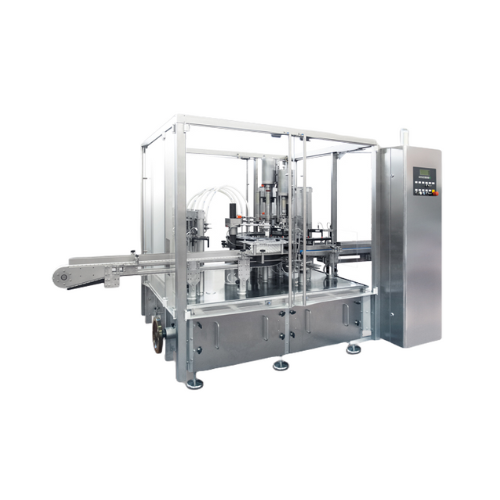

Volumetric filling and capping system for pharmaceuticals

Optimize your liquid filling and capping operations with a versatile system designed for precise dosing and seamless integration into existing packaging lines, ensuring high-performance and GMP compliance.

Fills and Caps Liquid Products Efficiently

The LA monobloc from Tecnicam is an engineered solution designed for high-precision filling and capping of liquid products, tailored for pharmaceutical and cosmetic manufacturers. Its standout feature is the volumetric filling system, utilizing up to eight dosing pumps with three micrometric adjustment eccentrics, ensuring precise measurements and consistency across all production runs. Designed for intermittent motion operations, the LA monobloc efficiently manages filling, prescrewing, and final capping, accommodating various cap types with optional screwing torque control. Engineered to meet GMP norms, its structure facilitates easy cleaning and maintenance through excellent accessibility between the transfer area and the machine bedplate.

The innovative transfer starwheel design allows rapid format changeovers and smooth laminar flow, crucial for maintaining sterility in production environments. Perfect for products like syrups, cosmetic serums, and skincare lotions, this monobloc easily integrates into existing manufacturing lines with its compact footprint and versatile automation setup. Additionally, the robust and reliable mechanical motion, driven by close-profile cams, enhances operational resilience and reduces downtime, making it a vital asset for high-throughput production cycles.

Benefits

- Ensures precision and consistency in filling processes, minimizing waste and product variance.

- Facilitates rapid format changeovers, increasing production flexibility and reducing downtime.

- Compliance with GMP norms enhances product safety and regulatory adherence.

- Compact and modular design allows seamless integration into existing packaging lines.

- Robust mechanical motion reduces maintenance demands, extending machine lifespan and reliability.

- Applications

- Cosmetics, Pharmaceuticals

- End products

- Hair oils, Pharmaceutical liquids, Skincare lotions, Liquid vitamins, Liquid medicines, Cosmetic serums, Syrups, Essential oils

- Steps before

- Bottle Cleaning, Bottle Preparation, Cap Sorting

- Steps after

- Quality Inspection, Labeling, Packaging, Sterilization

- Input ingredients

- bottles, caps, pharmaceutical materials, cosmetic materials

- Output ingredients

- filled bottles, capped bottles, pharmaceutical products, cosmetic products

- Market info

- CAM Packaging is known for its expertise in designing and manufacturing advanced packaging machinery tailored to client specifications, with a strong reputation for reliability and innovation in the engineered-to-order equipment market.

- Motion type

- Intermittent

- Filling system

- Volumetric with up to 8 dosing pumps

- Filling accuracy

- Extremely accurate with micrometric adjustment

- Capping capability

- Up to three different capping units

- Cap placement method

- Positive movement or pick-off positioning

- Screw-on caps

- Pre-screwing and successive final closure

- Automation

- Mechanical motion with close-profile cams

- Format change-over

- Rapid and easily repeatable

- Design

- Sterile environment regulation compliance

- Automation level

- PLC

- Changeover time

- Rapid

- Cleaning method

- Easy cleaning and inspection

- Batch vs. continuous operation

- Intermittent

- Filling and capping

- Integrated monobloc

- CIP/SIP

- None specified

- Format flexibility

- Ease of format change-over

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Filling purpose

- Pharmaceutical / Cosmetic

- Machine footprint

- Compact

- Discharge method

- Positive movement or pick-off positioning

- Control panel type

- PLC-controlled

- Conveyor frame design

- Sterile environment regulation compliant

- Format change-over

- Easy and rapid

- Transfer starwheel design

- Allows laminar flow application

- Filling system

- Volumetric with up to 8 dosing pumps

- Capping units

- Up to three different types

- Control panel type

- Modern design, GMP compliant

- Ease of format change-over

- Rapid, easily repeatable

- Capping units

- Up to three different types

- Conveyor frame design

- Sterile environment regulation compliant

- Volumetric filling system

- 8 dosing pump maximum

- Mechanical motion

- Close-profile cams