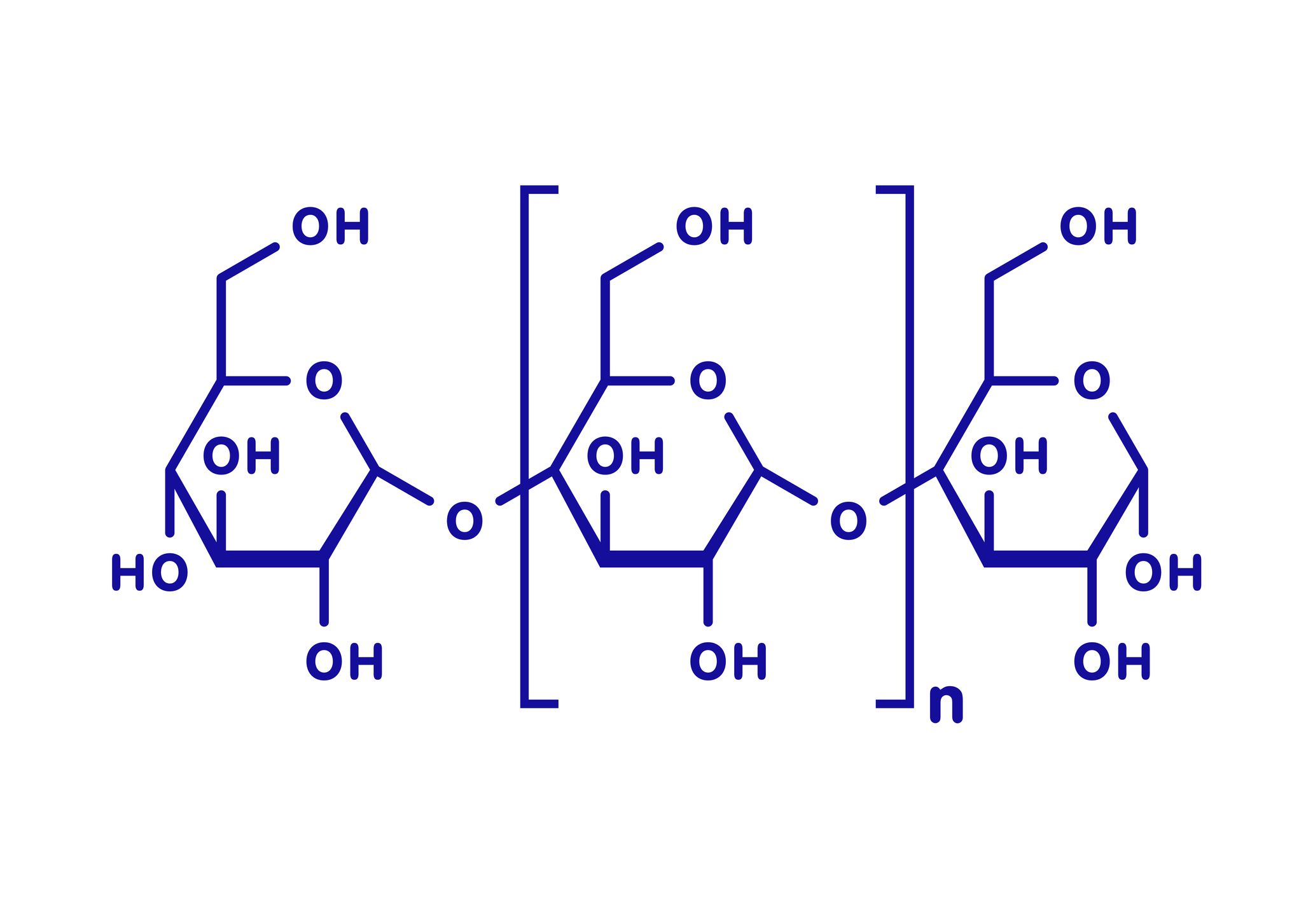

Continuous granulation dryer for chemical and polysaccharide applications

Enhance your production with precise drying and granulation, ensuring uniformity in particle size and moisture levels, ideal for intricate formulations and temperature-sensitive materials.

Dries and Granulates Multi-phase Products

The DRUVATHERM® Granulation Dryer from Lödige Maschinenbau is engineered for continuous drying and granulation of multi-phase products, offering a seamless operation ideal for complex production environments. By combining convection and contact drying within a fluidized bed, this equipment excels in handling materials with difficult flow characteristics, such as xanthan gum, battery cathode materials, and titanium powder. With its robust capacity for the chemical, food, and pharmaceuticals industries, it ensures reliable drying while maintaining product integrity. The machine’s design supports PLC integration for automation and precise control, optimizing energy usage through thermal energy application via heated jacket surfaces. Available in various material options to meet specific corrosion resistance requirements, the DRUVATHERM® complies with industry standards, ensuring safety and reliability. Easy to maintain, it features an optional CIP system that streamlines cleaning processes, enhancing productivity and reducing downtime.

Benefits

- Enhances product quality with consistent moisture control and granulation precision.

- Saves energy by utilizing efficient convection and contact drying methods.

- Minimizes product degradation with gentle, low-temperature drying.

- Improves process flexibility by accommodating a wide range of materials and consisitencies.

- Increases production uptime with reliable continuous operation and easy-to-maintain design.

- Applications

- Food, Polysaccharides, Metallurgy, Building materials, Cosmetics, Chemical industry, Environment, Plastics, Batteries, Pharmaceuticals

- End products

- Battery cathode materials, Compost stabilizers, Polypropylene powder, Tablet coatings, Silicon carbide ceramics, Instant soup powders, Titanium powder, Foundation creams, Catalysts, Xanthan gum

- Steps before

- Mixing, Granulation, Formulation Preparation

- Steps after

- Product Formulation, Quality Testing, Packing

- Input ingredients

- substances with problematic flow characteristics, substances with changing consistency, multi-phase process materials

- Output ingredients

- dried products, granulated products, defined grain size distribution

- Market info

- Loedige Process Technology is renowned for its expertise in industrial mixing, granulation, drying, and coating technologies, offering engineered-to-order solutions for various industries, including pharmaceuticals, chemicals, and food processing.

- Drying method

- Convection and contact drying

- Operation type

- Continuous

- Temperature range

- Low temperatures

- Product retention time control

- Yes

- Mixing technology

- Fluid bed

- Heat exchange method

- Heated drum walls

- Average product retention time

- Controlled

- Granulation capability

- Simultaneous

- Product grain size distribution

- Defined

- Atmosphere for drying

- Normal or inert

- Flow type

- Co-current and counter-current

- System adaptability

- High

- Chopper usage

- Optional

- Heat source

- Jacket surfaces and high-temperature gases

- Batch vs. continuous operation

- Continuous

- Automation level

- PLC / SCADA

- Changeover time

- Short

- Cleaning method

- CIP

- Energy efficiency

- High, due to convection and contact drying

- Gentle product treatment

- Yes

- Simultaneous product granulation

- Possible

- Adaptation of retention time

- Yes, based on specific process needs

- Density/particle size

- 0.5–2.5 g/cm³ / 50–1000 µm

- Problematic flow characteristics

- Multi-phase process handling

- Agglomeration risk

- Controlled granulation

- Tank shape

- Cylindrical

- Feed method

- Continuous

- Discharge method

- Continuous

- Control panel type

- PLC-controlled

- Integration possibilities

- Co-current and counter-current flow

- Discharge method

- Continuous operation

- Automation level

- Manual / PLC / SCADA

- Retention time adaptation

- Customizable